Cellulose fibre composition

A composition and cellulose technology, applied in the direction of secondary cellulose fiber, non-fibrous pulp addition, fiber raw material treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

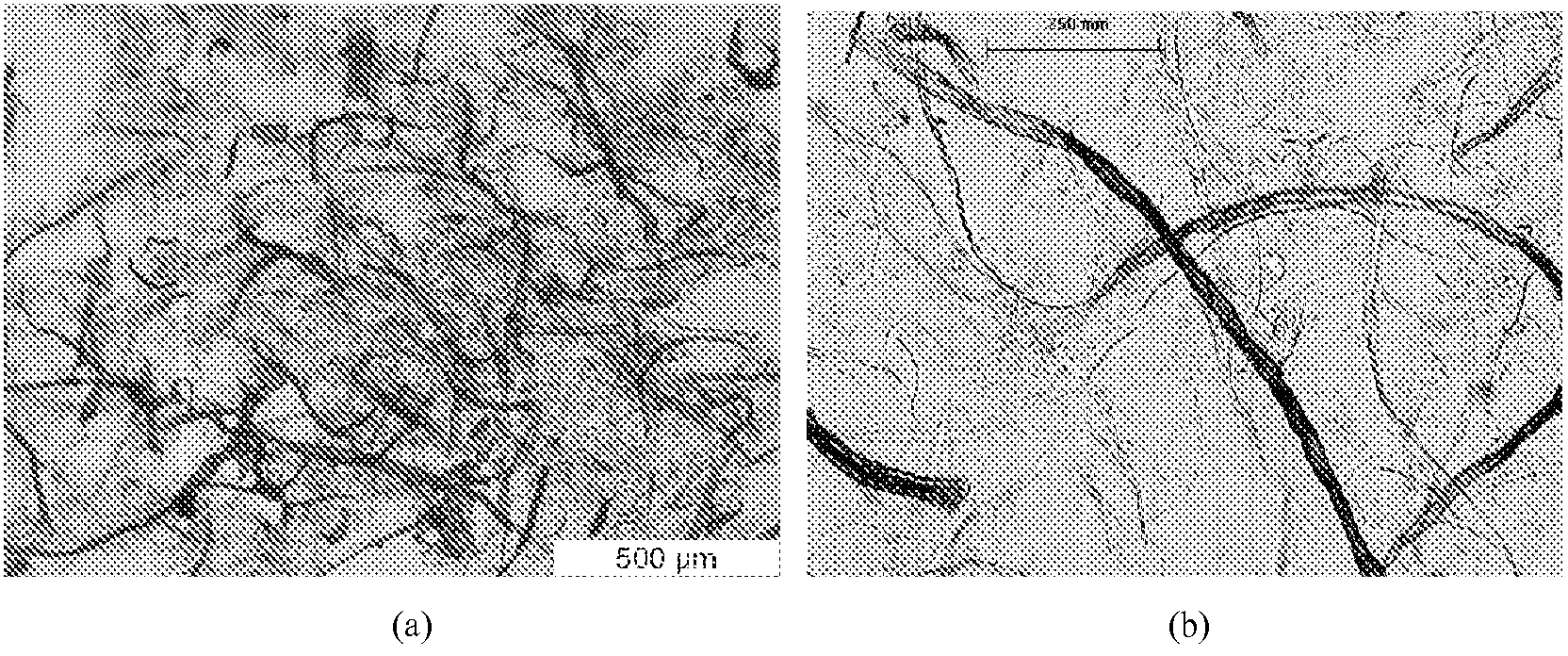

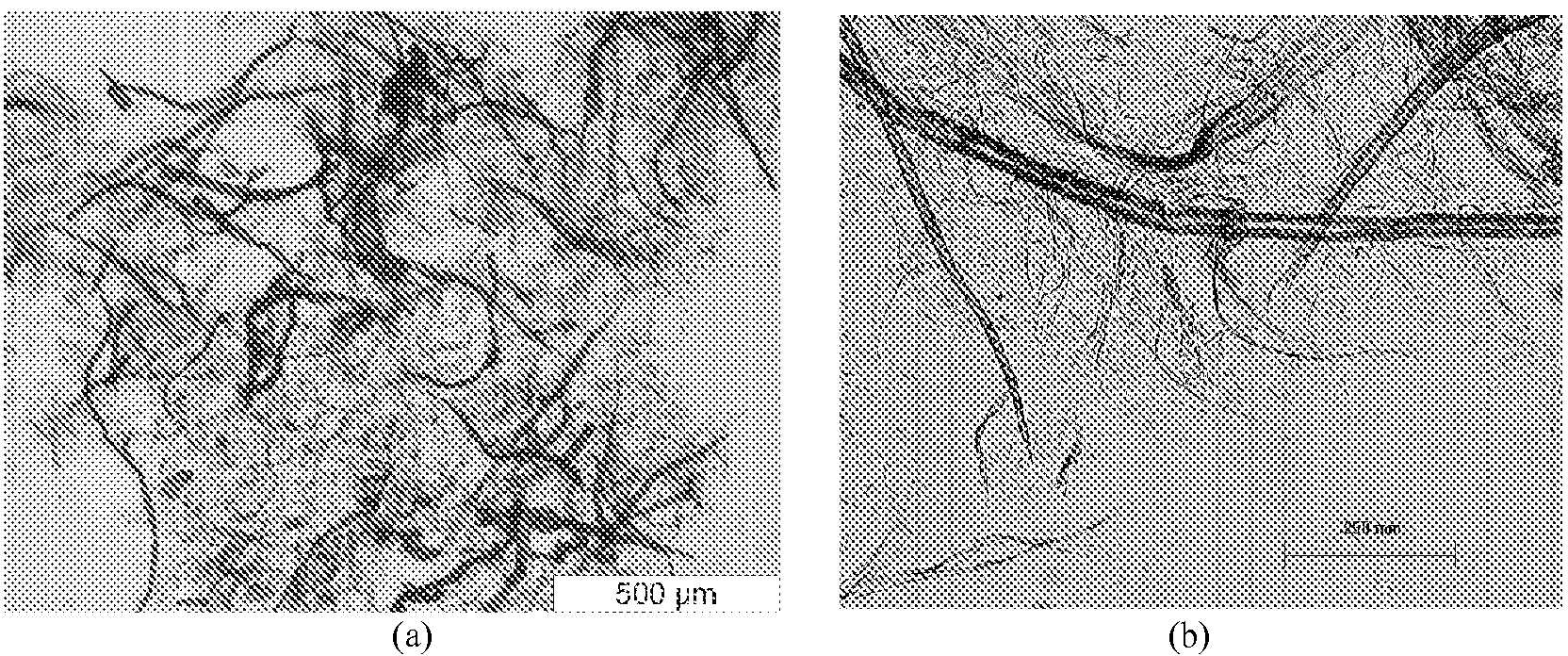

[0057] Fiber furnish and degree of fibrillation

[0058] Five samples (A-E) of waste paper based, RCW80 deinked waste paper recovered from Amcor and one sample (F) of hemp cellulose based Hempcell B from Celesa, Spain, were subjected to grinding in a high concentration 22" refiner The fiber (solids) content in the slurry was 16 wt% and the flow rate of the slurry through the refiner was about 200 L / min. The specific energy (the amount of energy transferred from the motor of the refiner to the fibers) input for these samples was :

[0059]

[0060] The specific edge load (the amount of energy applied one meter across the edge of the rod of the refiner plate and transferred to the slurry in one second) was 4-8 Ws / m at the beginning of the refining process, and this load was carried over to the process At the end, gradually reduce to between 1-4Ws / m.

[0061] The fibers are processed until the spread of the average fiber length matches the known "bell curve". Empirically an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com