Electronic equipment with asymmetrical heat dissipation structure

A technology of heat dissipation structure and electronic equipment, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of large dielectric loss coefficient, signal transmission loss, signal loss, etc., and achieve large effective heat dissipation area, large welding area, and efficient heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

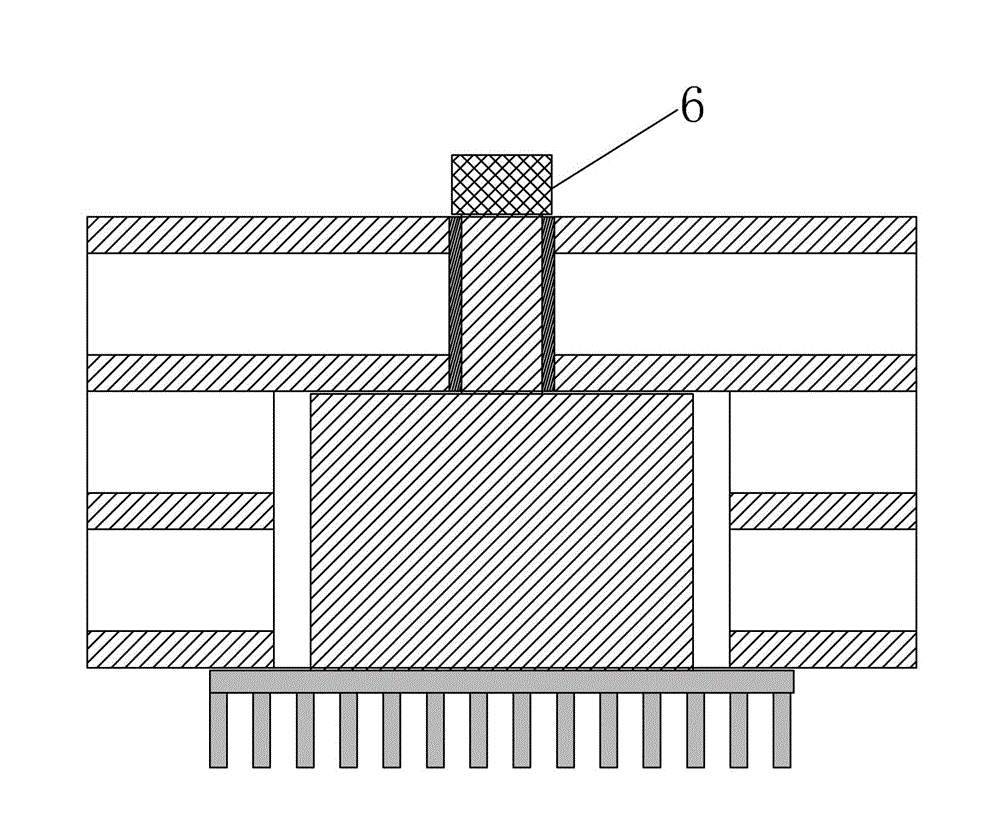

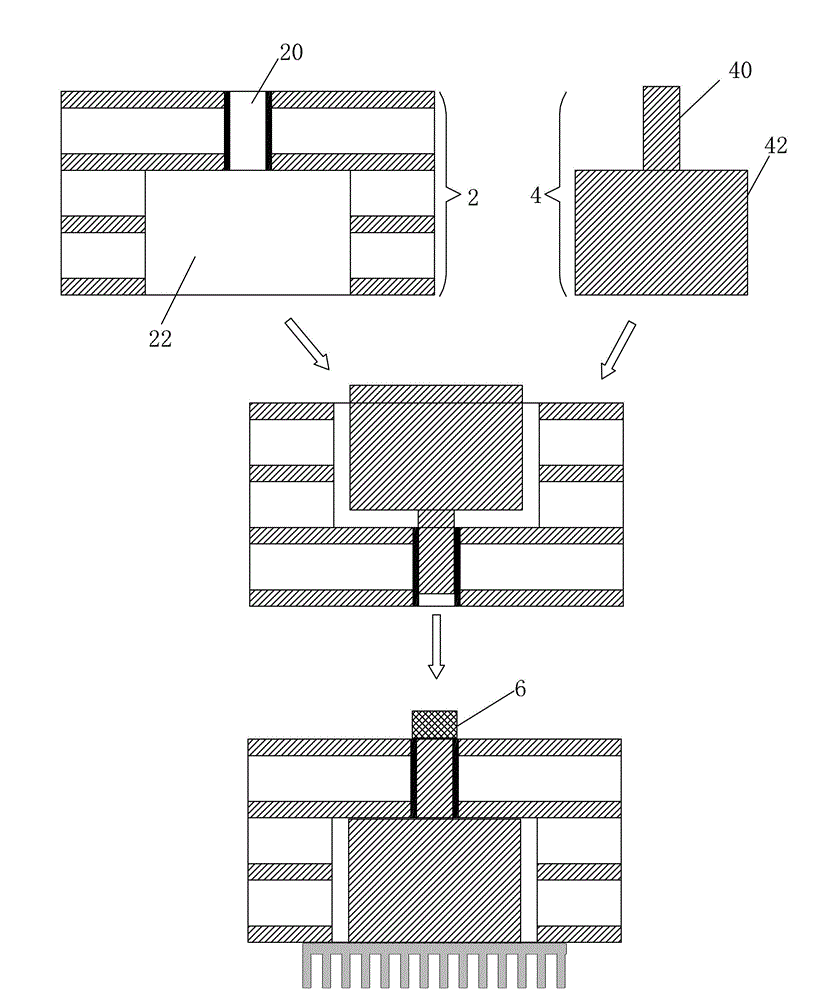

[0022] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0023] see figure 1 and figure 2 , the present invention provides an electronic device with an asymmetric heat dissipation structure, comprising: a PCB substrate 2, a heat-conducting metal core 4 installed in the PCB substrate 2, and a high-power micro-device 6 installed on the heat-conducting metal core 4, the heat-conducting The metal core 4 includes a base 42 and a protrusion 40 extending from the base 42. The size of the protrusion 40 is set corresponding to the micro high-power device 6. The size of the base 42 is larger than the size of the protrusion 40. The micro high-power device 6 is mounted on the raised portion 40 .

[0024] The PCB substrate 2 is provided with a first groove 20 corresponding to the protruding portion 40, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com