Composite copper bush and preparation method thereof

A technology of copper sleeves and inner copper sleeves, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of affecting the stability of the amorphous forming process, small contact area, and reduced thermal conductivity. Increase the effective heat dissipation area, high heat exchange capacity, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

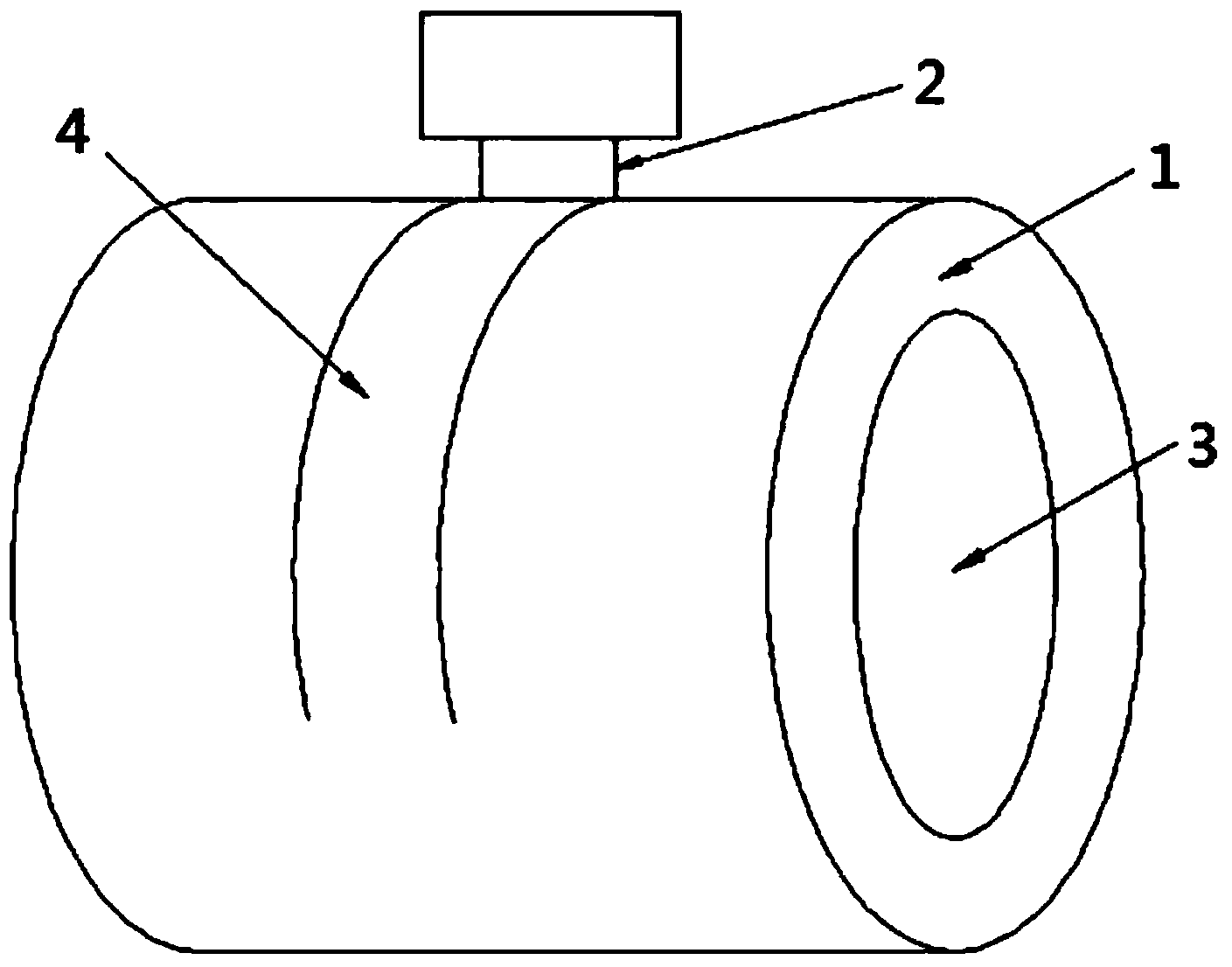

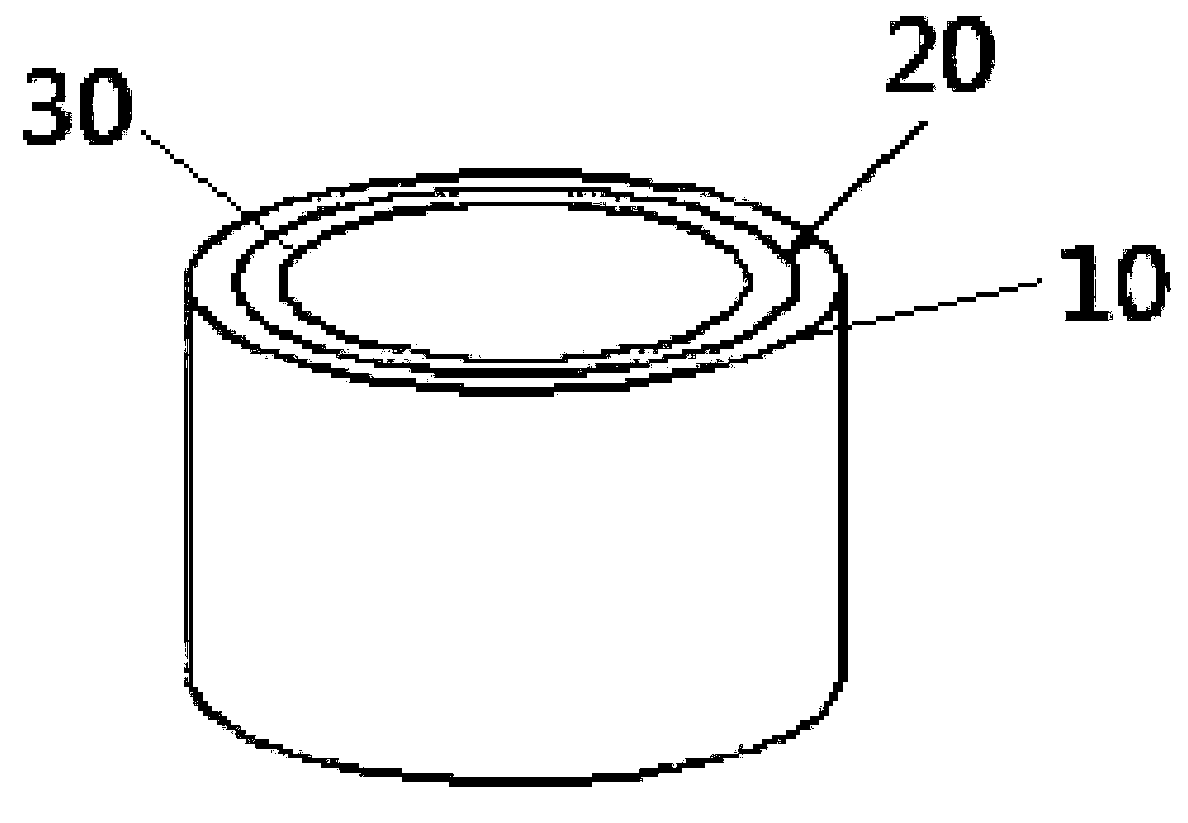

[0032] An embodiment of the composite copper sleeve of the present invention, as attached image 3 As shown, the composite copper sleeve described in this embodiment includes an outer copper sleeve 10 closely fitted together, a lateral high thermal conductivity material layer 20 and an inner copper sleeve 30 from outside to inside, and the thickness of the outer copper sleeve 10 is 5-30 mm, the thickness of the lateral high thermal conductivity material layer 20 is 0.1-1.5 mm, the thickness of the inner copper sleeve 30 is 5-15 mm, and those skilled in the art can select an outer copper sleeve with a suitable thickness according to actual needs, Lateral layers of high thermal conductivity material and inner copper sleeve.

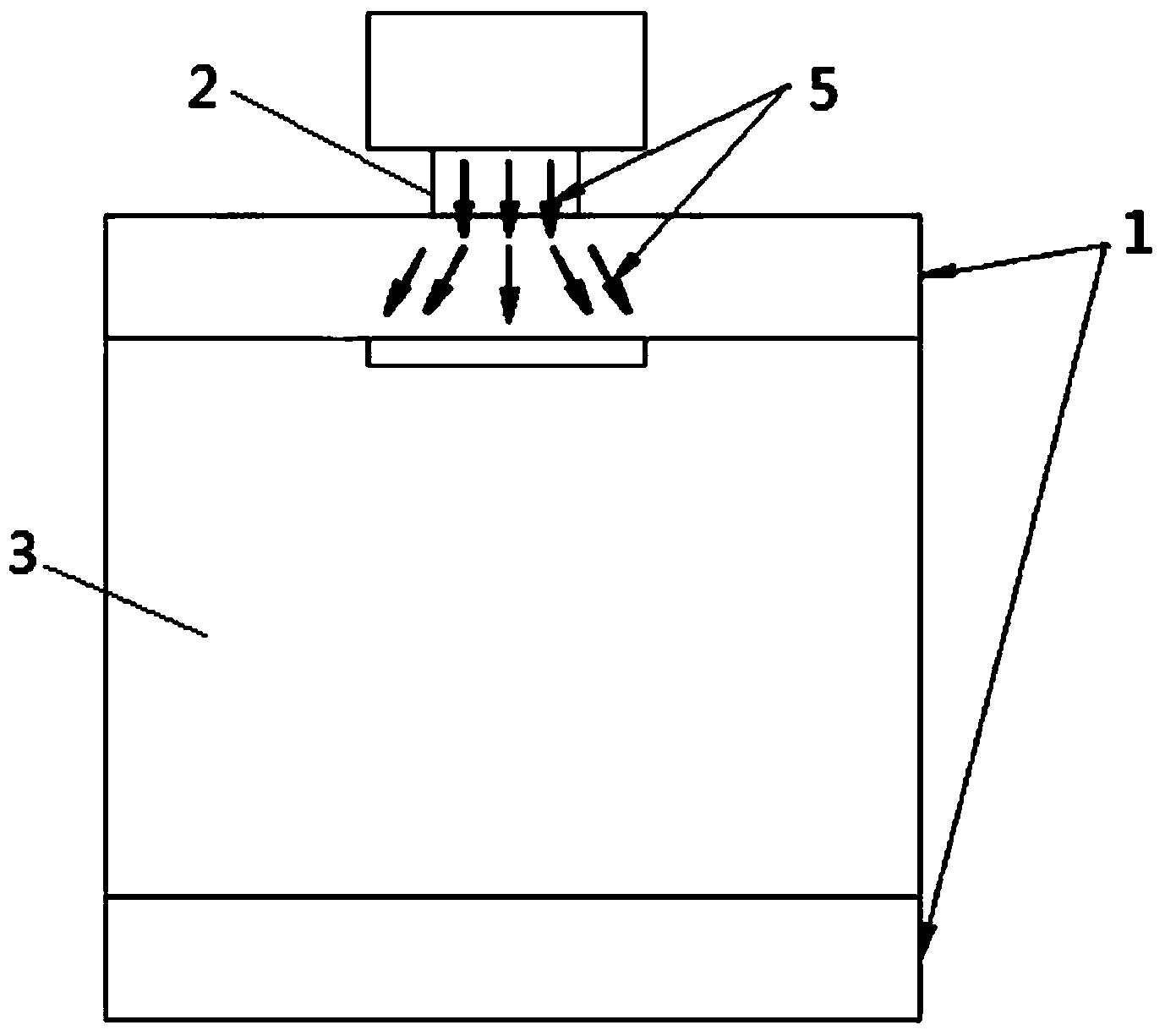

[0033] as attached Figure 4 As shown, the composite copper sleeve described in this embodiment is prepared by the following method:

[0034] (1) Preparation of the outer copper sheath: using chromium-zirconium copper to prepare the inner and outer smooth...

Embodiment 2

[0042] Cooling effect experiment of composite copper sleeve of the present invention

[0043] Use a 100kg level amorphous strip machine to make strips, the composition grade is 1k101, the temperature of the molten steel is controlled at 1000-1450°C, and the existing cooling copper sleeve and the composite copper sleeve of the present invention are respectively used for cooling. The experimental results are shown in Table 1. :

[0044] Table 1 Comparison of cooling effects

[0045] project

[0046] It can be seen from Table 1 that the composite copper sleeve of the present invention can effectively improve the cooling efficiency, improve the performance of amorphous and nanocrystalline products, and the product pass rate of amorphous and nanocrystalline belt making equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com