Wind driven generator

A technology for wind turbines and ventilation pipes, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., which can solve the problems of difficulty in improving the cooling efficiency and the limited effective heat dissipation area of the stator, and achieve the improvement of cooling effect and increase Large effective heat dissipation area and low electromagnetic influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

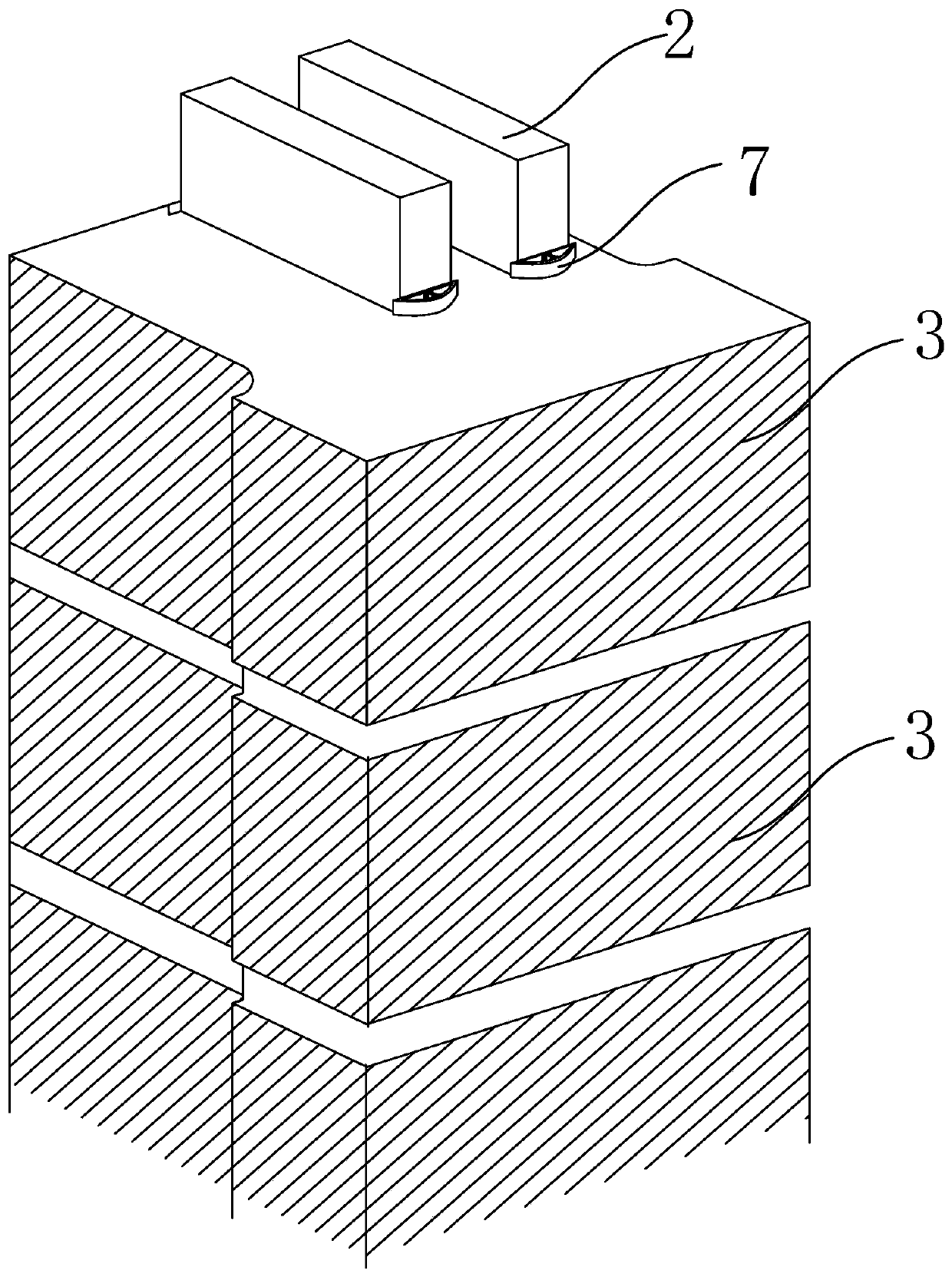

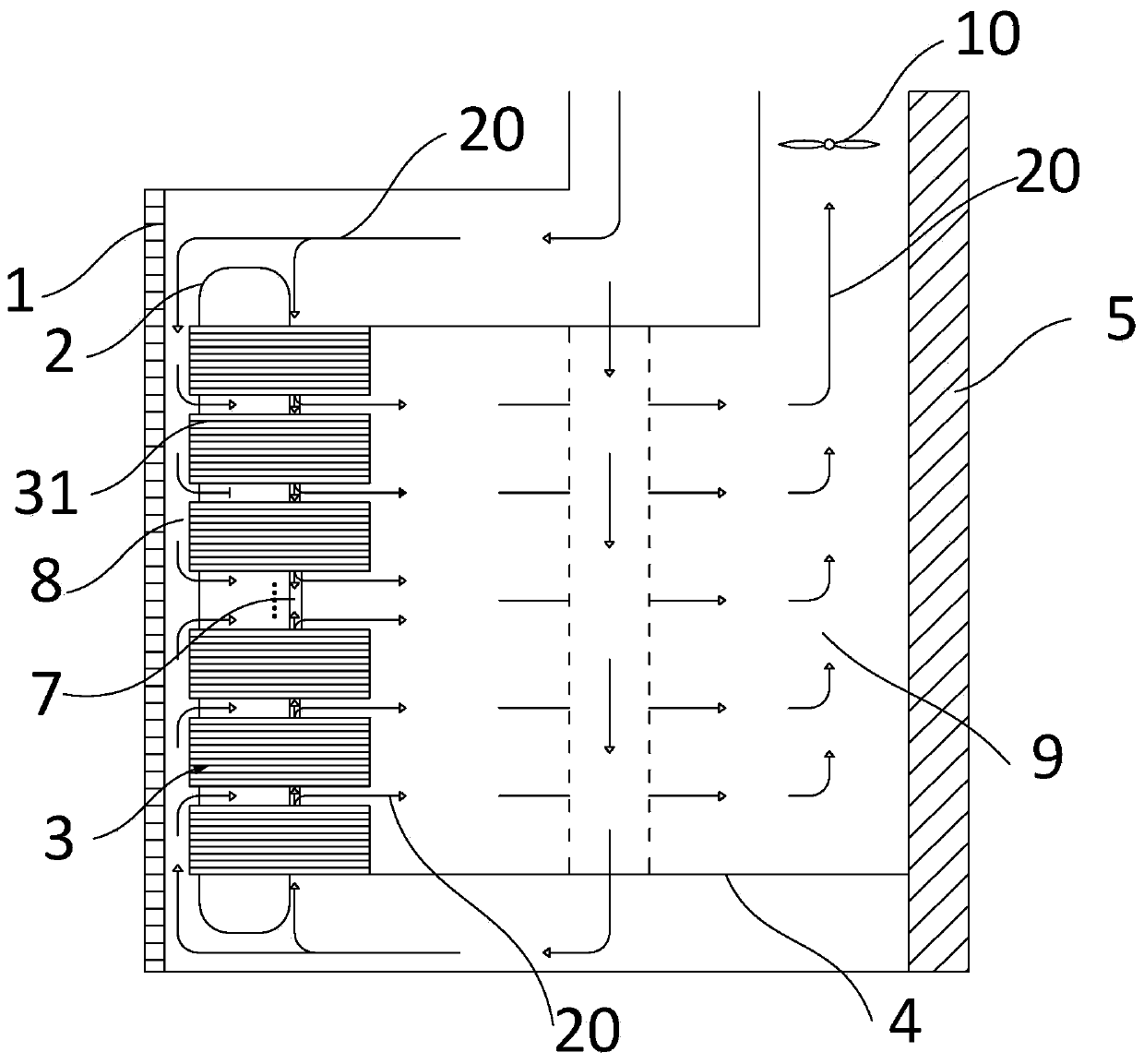

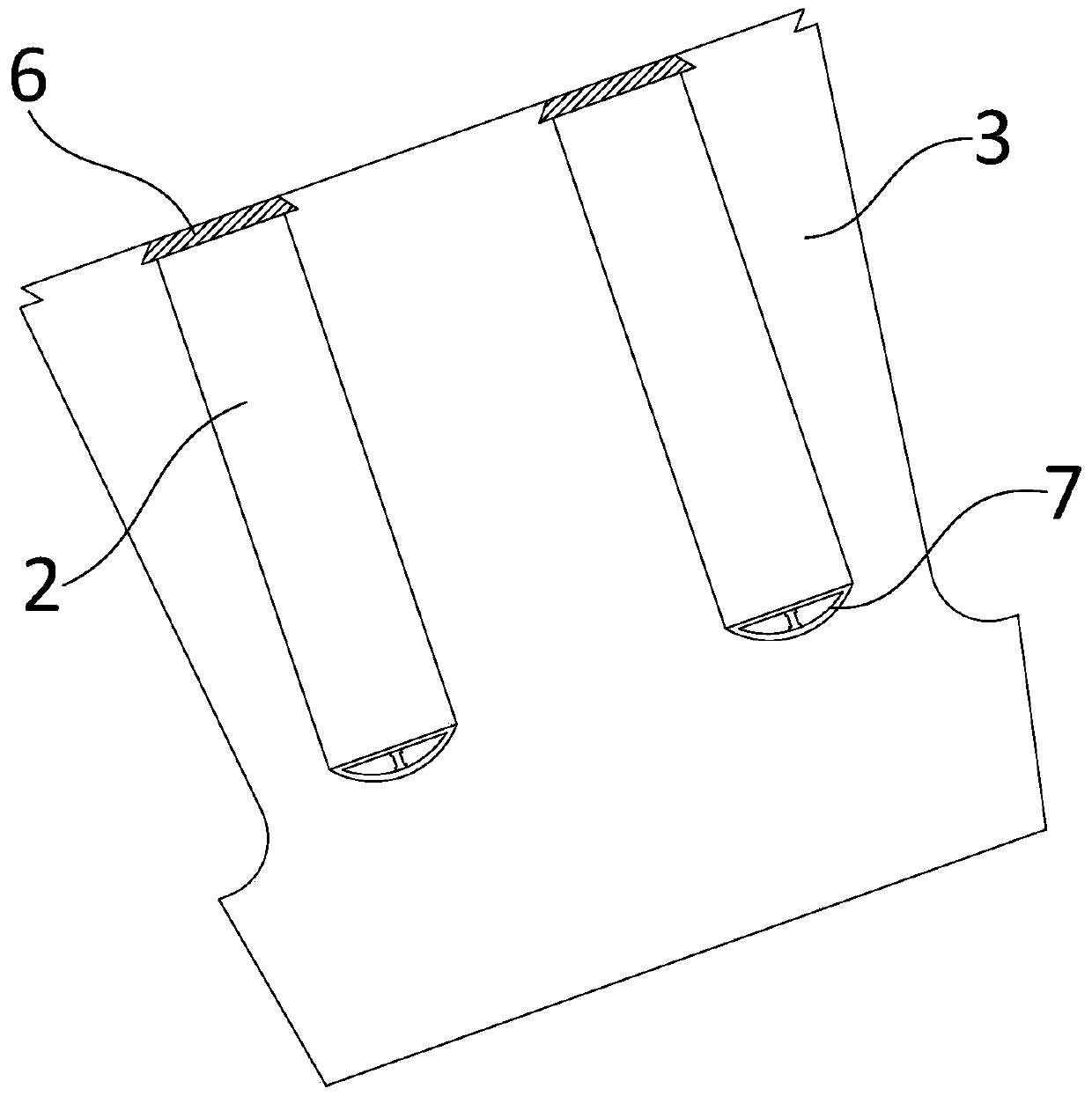

[0047] Such as Figure 1 to Figure 3 As shown, the present invention provides a wind generator, which includes a rotor 1, a stator and an air gap 8 between the rotor 1 and the stator, the stator includes a stator coil 2 and a stator core 3, and the radial inner side of the stator core 3 , The internal space enclosed by the stator central part 5 and the stator end plate 4 forms a cavity 9 . The stator core 3 has a tooth slot structure, and the stator coil 2 is located in the slot of the stator core 3 . The stator core 3 includes a number of laminations 31 with gaps between them. The laminations 31 are formed by stacking a plurality of silicon steel sheets with cogged structures along the axial direction of the wind turbine. The two ends of the stator core 3 It is compressed and fixed by the stator end plate 4 along the axial direction of the generator. The space between each lamination group 31 forms a radial ventilation channel of the stator, and the radial ventilation chann...

Embodiment 2

[0057] Such as Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the ventilation pipe 7 is composed of several ventilation components 72 . Both ends of the ventilation assembly 72 are movably connected to each other to form an integral ventilation pipe 7 . One end of the two ventilation components 72 located at the two ends of the installation groove is respectively provided with an axial fixing structure for preventing the displacement of the ventilation pipe 7 in the axial direction of the stator.

[0058] One end of the ventilation component 72 is provided with at least one protrusion, and the other end is provided with a connection groove corresponding to the protrusion, and the ventilation components 72 are connected to each other through the protrusion and the connection groove. In other embodiments, two adjacent ventilation components 72 may also be connected by bonding or other flexible connectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com