Iron core structure of distribution transformer special for electric vehicle

A technology for distribution transformers and electric vehicles, applied in the field of transformers, can solve the problems of slow heat dissipation in the thickness direction, reduced transformer life, and high transformer temperature, and achieve the effects of reducing the amount of materials used, reducing the amount of materials, and reducing temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

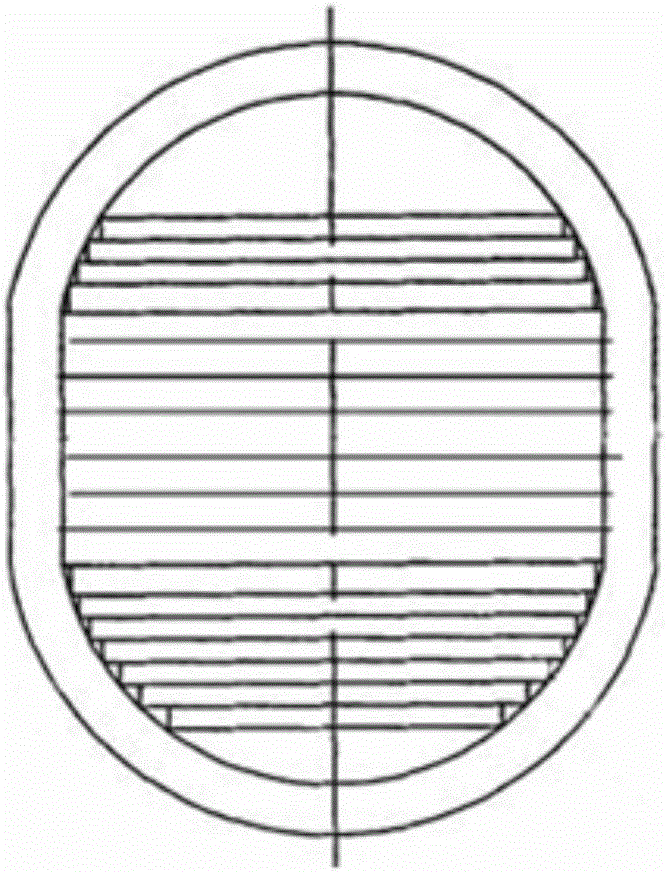

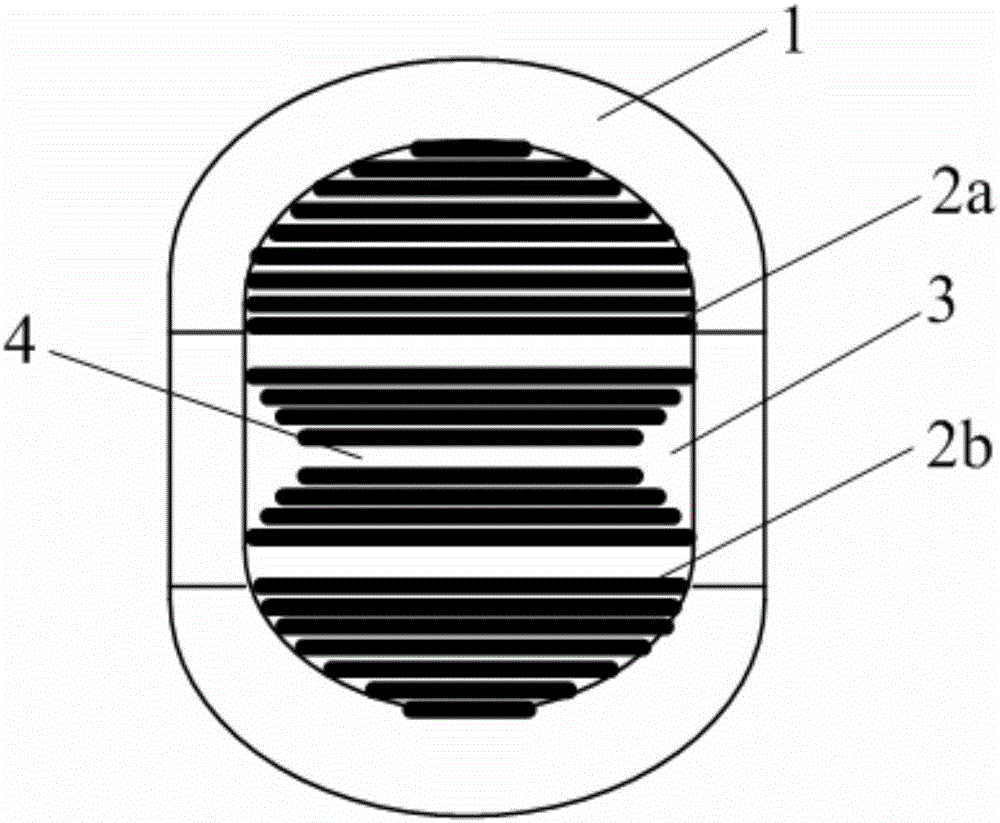

[0026] Such as figure 2 As shown in the figure, there is a distribution transformer core structure for electric vehicles. There are several stacked core unit chips inside the core. The multiple core unit chips have similar shapes and different cross-sectional areas. The core unit chips are arranged along the iron core. The core is arranged in the axial direction, and the core unit chip is covered with an insulating layer. The cross-sectional shape of the iron core is an oblong structure, and the insulating layer is also an oblong structure. The insulating layer includes an arc segment and is tangent to the arc segment. straight line segment;

[0027] One chip and two chips are respectively arranged inside the iron core at the tangent between the arc segment and the straight line segment. The core unit chips are stacked between the first chip and the two chips to form an iron core assembly with a double-stepped cross section. And the cross-sectional area of the iron core un...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the core unit chip is made of iron-based nanocrystalline alloy.

[0033] Those skilled in the art can understand that, unless otherwise defined, all terms (including technical and scientific terms) used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. It should also be understood that terms such as those defined in commonly used dictionaries should be understood to have a meaning consistent with the meaning in the context of the prior art, and will not be interpreted in an idealized or overly formal sense unless defined as herein Explanation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com