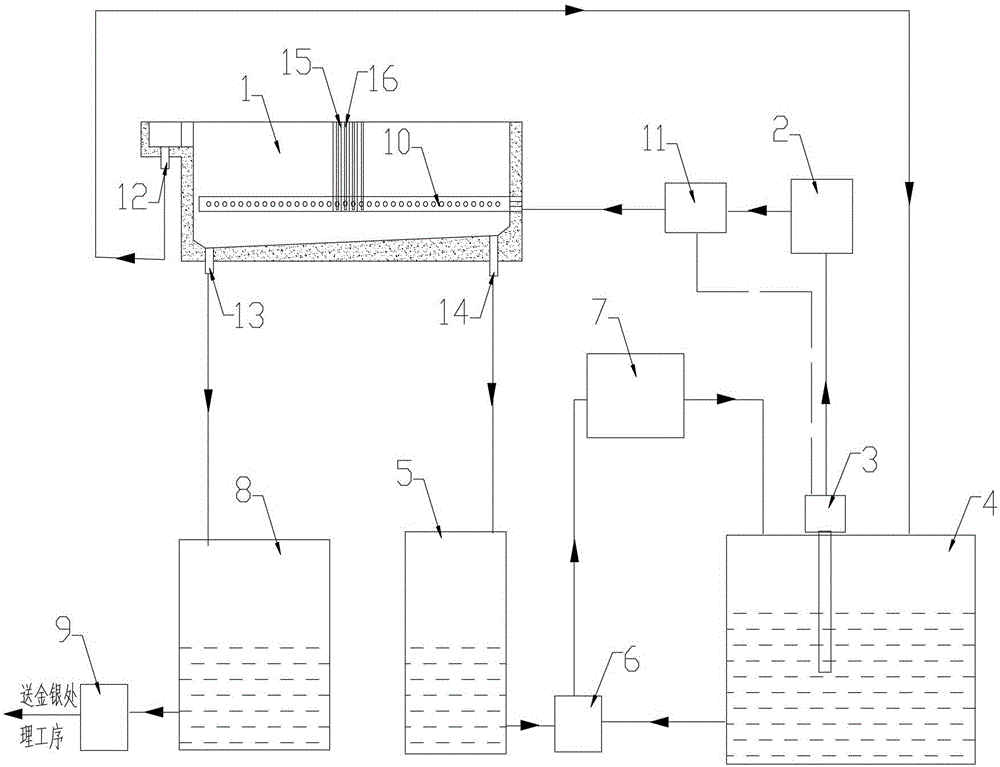

A copper electrolysis system and its operation method

A technology for copper electrolysis and electrolyte, applied in the field of copper electrolysis, can solve the problems of high production cost, low production cost, low current density, etc., and achieve the effects of reducing contact potential difference, improving circulation speed, and preventing concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

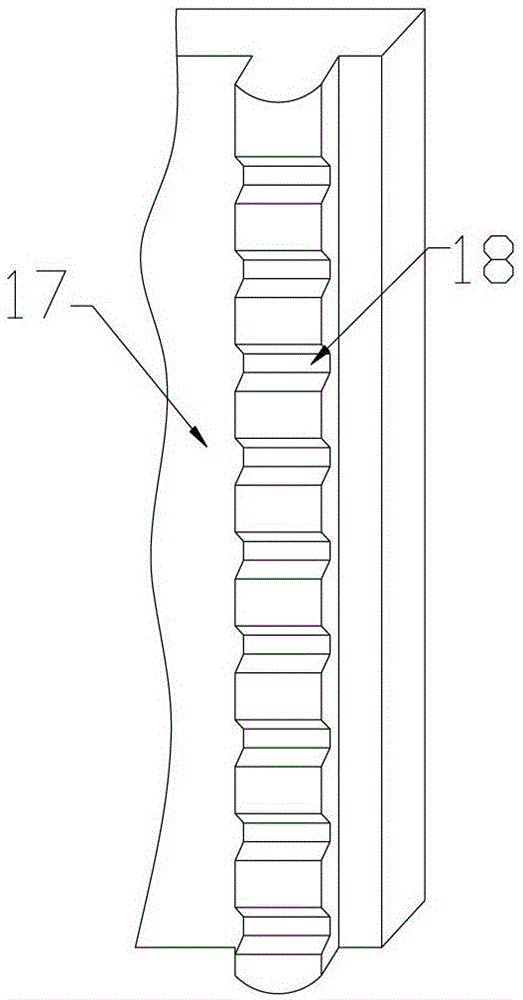

Method used

Image

Examples

Embodiment 1

[0061] Place 54 thick copper anode plates and 53 pure copper cathode plates at intervals in the electrolytic cell, with Cu 2+ The concentration is 45g / l, and the concentration of free acid is 180g / l as the electrolyte. Start the frequency conversion pump to transport the electrolyte to the electrolytic cell through the electrolyte supply pipeline, and the electrolyte is supplied to it through the liquid supply device. It is sprayed in the direction close to the cathode plate, and then the sprayed electrolyte moves through the cavity between the plate and the side wall of the tank, and the cavity between the plate and the bottom of the tank to both ends of the tank, and finally from The overflow ports at both ends of the tank return to the electrolyte circulation system.

[0062] The process parameters of the electrolysis are as follows: the flow rate of the electrolyte is 110L / min, the pressure of the electrolyte is 0.3MPa, the temperature of the electrolysis is 58°C, and the ...

Embodiment 2

[0064] Place 54 thick copper anode plates and 53 pure copper cathode plates at intervals in the electrolytic cell, with Cu 2+ The concentration is 58g / l, and the concentration of free acid is 165g / l as the electrolyte. Start the frequency conversion pump to transport the electrolyte to the electrolytic cell through the electrolyte supply pipeline. The electrolyte is supplied to it through the liquid supply device. It is sprayed in the direction close to the cathode plate, and then the sprayed electrolyte moves through the cavity between the plate and the side wall of the tank, and the cavity between the plate and the bottom of the tank to both ends of the tank, and finally from The overflow ports at both ends of the tank return to the electrolyte circulation system.

[0065] The process parameters of electrolysis are as follows: the flow rate of electrolyte is 90L / min, the pressure of electrolyte is 0.25MPa, the temperature of electrolysis is 66°C, and the current density is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com