Collagen hydrogel for injection and preparation method thereof

A collagen and collagen polypeptide technology, which is applied in the field of collagen hydrogel for injection and its preparation, can solve the problems of strong biological toxicity, time-consuming, and difficulty in dissolving, so as to reduce the damage to the injection site and the human body, and reduce the degradation. speed, and the effect of improving retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Step 1: dissolving collagen in an alkaline solution to prepare a solution with a collagen concentration of 5%.

[0062] Collagen is selected from full-length collagen extracted from animal tissues.

[0063] The alkaline solution is sodium hydroxide solution with a molar volume concentration of 0.05 mol / L.

[0064] Step 2: Add epoxy compound as a crosslinking agent, the amount added is 0.5% of the solution mass, the reaction temperature is 35°C, the reaction time is 10 hours, and left to cool.

[0065] The epoxy compound is selected from 1,4-butanediol diglycidyl ether.

[0066] Step 3: Pulverizing the obtained product.

[0067] Select extrusion as the crushing method.

[0068] Step 4: Wash the obtained granular product in a buffer solution 10 times its volume for 1 day.

[0069] The buffer is a phosphate buffer with a molar volume concentration of 0.01 mol / L and a pH of 6.

[0070] Step 5: Remove the buffer by centrifugation, and collect the precipitate to obtain a...

Embodiment 2

[0072] Step 1: dissolving collagen in an alkaline solution to prepare a solution with a collagen concentration of 5%.

[0073] Collagen is selected from collagen peptides extracted from animal tissues.

[0074] The alkaline solution is sodium hydroxide solution with a molar volume concentration of 0.1 mol / L.

[0075] Step 2: Add epoxy compound as a crosslinking agent, the amount added is 2% of the solution mass, the reaction temperature is 40°C, the reaction time is 10 hours, and left to cool.

[0076] Epoxy compounds are selected from ethylene glycol diglycidyl ether.

[0077] Step 3: Pulverizing the obtained product.

[0078] Select extrusion as the crushing method.

[0079] Step 4: Wash the obtained particle product in a buffer solution 20 times its volume for 1 day.

[0080] The buffer is a phosphate buffer with a molar volume concentration of 0.02 mol / L and a pH of 6.

[0081] Step 5: Remove the buffer by centrifugation, and collect the precipitate to obtain a granul...

Embodiment 3

[0083] Step 1: dissolving collagen in alkaline solution to prepare a solution with a collagen mass concentration of 10%.

[0084] Collagen is selected from gelatin extracted from animal tissue.

[0085] The alkaline solution is potassium hydroxide solution with a molar volume concentration of 0.2 mol / L.

[0086] Step 2: Add epoxy compound as cross-linking agent, the addition amount is 4% of the solution mass, the reaction temperature is 45°C, the reaction time is 20 hours, and left to cool.

[0087] The epoxy compound is selected from 1,6-hexanediol diglycidyl ether.

[0088] Step 3: Pulverizing the obtained product.

[0089] The grinding method is selected as grinding.

[0090] Step 4: Wash the obtained particle product in a buffer solution 30 times its volume for 1 day.

[0091] The buffer is a phosphate buffer with a molar volume concentration of 0.03 mol / L and a pH of 6.

[0092] Step 5: Remove the buffer by centrifugation, and collect the precipitate to obtain a gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

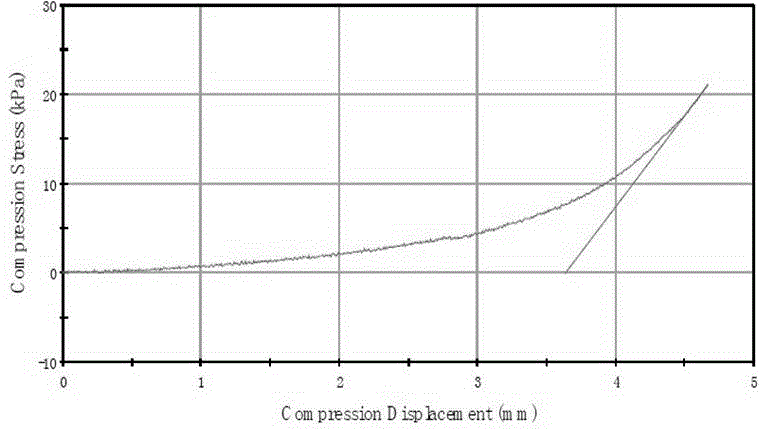

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com