Preparation method of polyurethane modified acrylic resin for reflecting material

A polyurethane modification, acrylic resin technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc. Capacitance, improve the effect of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

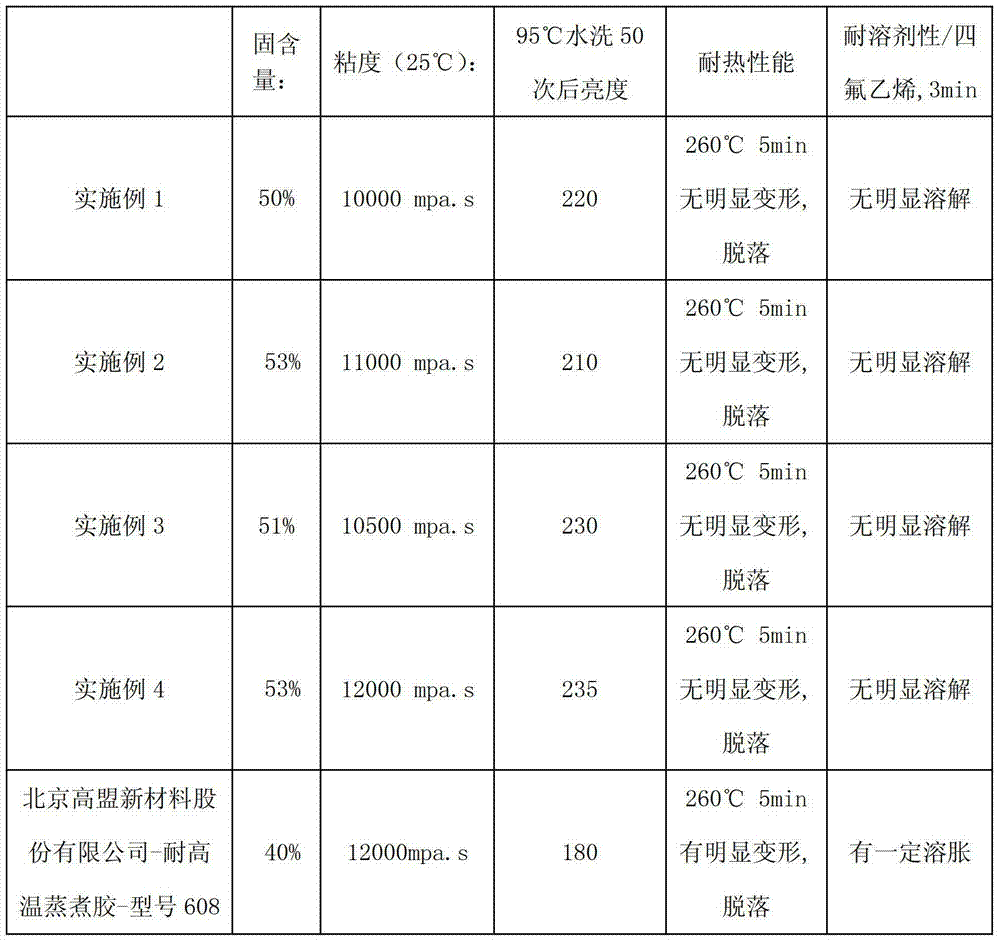

Embodiment 1

[0058] (1) Preparation of active acrylate polymer

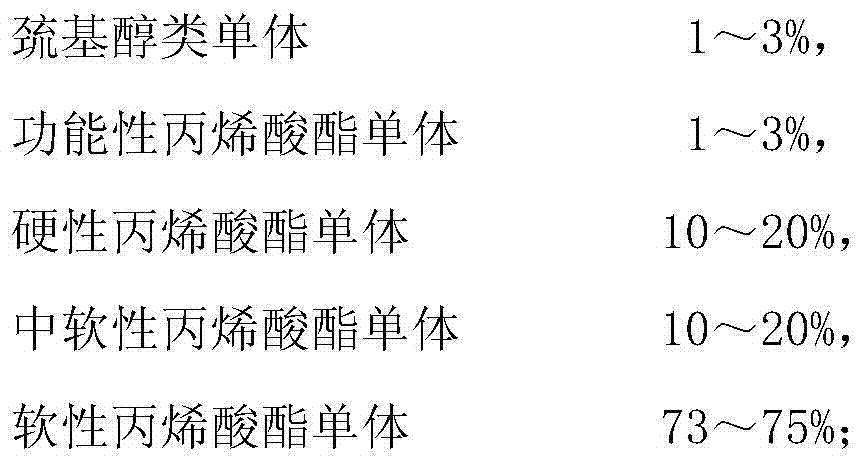

[0059] Based on the total weight of comonomers, weigh 2% mercaptoethanol, 1% hydroxyethyl acrylate, 35.2% butyl acrylate, 39.8% isooctyl acrylate, 10% methyl methacrylate, and 10.1% ethyl acrylate , 1.9% methyl acrylate, 0.4% azobisisobutyronitrile, 100% ethyl acetate, add the monomer mixture and 2 / 3 solvent into the reaction kettle, start the stirring and start to quickly heat up to reflux, reflux for 1h, and then drop Add the initiator solution consisting of the initiator and the remaining 1 / 3 of the solvent, and drop it evenly within 3 hours, then keep it warm for 3 hours, cool to about 30°C and filter out the material, with a solid content of 50%.

[0060] (2) Preparation of isocyanate-terminated prepolymer

[0061] Weigh polyester polyol (hydroxyl value 47mgKOH / g, acid value 0.4mgKOH / g) 90.2%, toluene diisocyanate 9.8%, organic solvent 100%, R (molar ratio of isocyanate group to hydroxyl group) = 1.5, Add polyester pol...

Embodiment 2

[0066] (1) Preparation of active acrylate polymer: based on the total weight of comonomers, weigh 75% of isooctyl acrylate, 11% of methyl methacrylate, 1% of 3-mercapto-1-propanol, hydroxyacrylate 2% of propyl ester, 10.1% of butyl methacrylate, 0.9% of methyl acrylate, 0.5% of azobisisobutyronitrile, 70% of ethyl acetate, 10% of toluene, the process condition of polymerization is carried out by embodiment 1, solid The content is 55%.

[0067] (2) Preparation of isocyanate-terminated prepolymer

[0068] Weigh polyester polyol (hydroxyl value 44mgKOH / g, acid value 0.4mgKOH / g) 90.2%, toluene diisocyanate 9.8%, organic solvent 120%, R (molar ratio of isocyanate group to hydroxyl group) = 1.6, Add polyester polyol and 20% organic solvent into the reaction kettle, start stirring, heat up for dehydration, stop heating when the dehydration temperature reaches 140°C, about 12% of the organic solvent will come out, cool down to 65°C, add toluene diisocyanate, and control the temperatu...

Embodiment 3

[0073] (1) Preparation of active acrylate polymer: Based on the total weight of comonomers, weigh 43% of isooctyl acrylate, 30% of tridecyl acrylate, 11% of isobornyl methacrylate, 3-mercapto -2-butanol 1%, hydroxypropyl acrylate 2%, lauryl acrylate 11.1%, methyl acrylate 1.9%, azobisisobutyronitrile 0.5%, ethyl acetate 70%, toluene 10%, polymerization process Condition is carried out by embodiment 1, and solid content is 55%.

[0074] (2) Preparation of isocyanate-terminated prepolymer

[0075] Weigh polyester polyol (hydroxyl value 47mgKOH / g, acid value 0.4mgKOH / g) 90.2%, toluene diisocyanate 9.8%, organic solvent 120%, R (molar ratio of isocyanate group to hydroxyl group) = 1.5, Add polyester polyol and 20% organic solvent into the reaction kettle, start stirring, heat up for dehydration, stop heating when the dehydration temperature reaches 140°C, about 12% of the organic solvent will come out, cool down to 65°C, add toluene diisocyanate, and control the temperature at 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com