A method for preparing boron-nitrogen co-doped graphitized nano-carbon with biomass as carbon source

A nano-carbon and graphitization technology, applied in nano-carbon, graphene, nanotechnology and other directions, can solve the problems of low boron and nitrogen content, high cost, complex preparation process, etc., achieve uniform product morphology and properties, reduce synthesis Cost, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

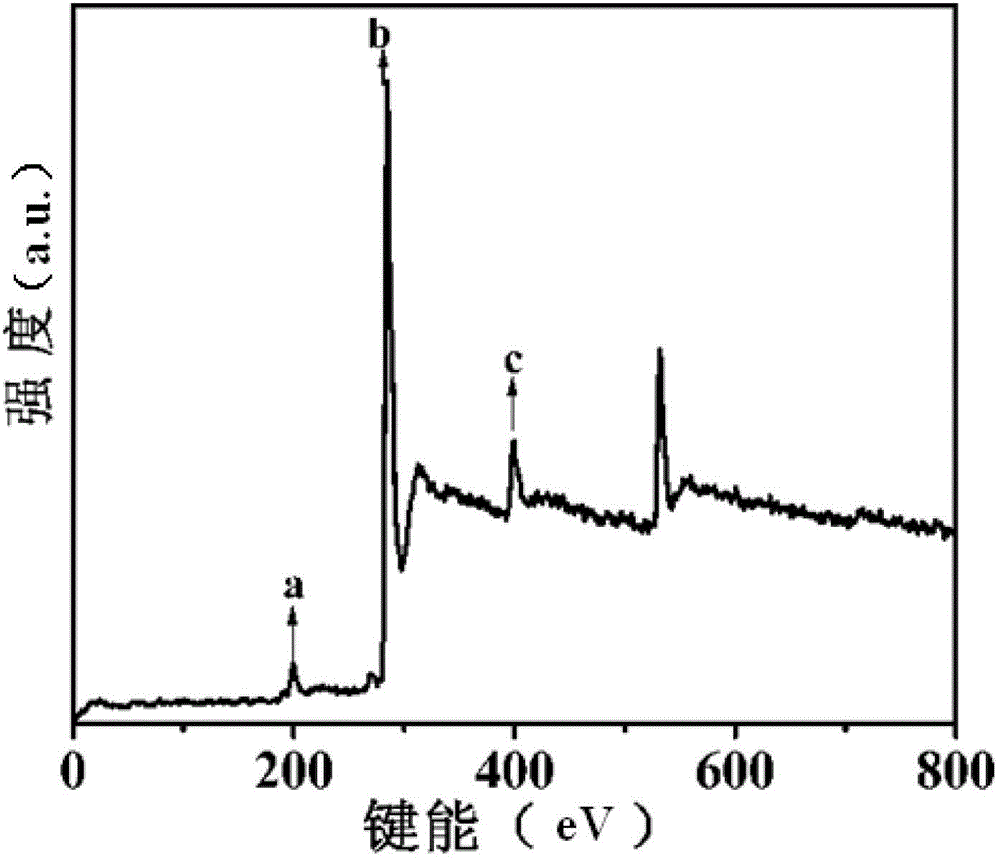

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: In this embodiment, a method for preparing boron-nitrogen co-doped graphitized nano-carbon using biomass as a carbon source is specifically carried out according to the following steps:

[0017] 1. Using chemical methods to pretreat biomass;

[0018] 2. Add the biomass treated in step 1 into the solvent, then add a compound containing boron element, a compound of nitrogen element and a graphitization catalyst, and then stir at a temperature of 25°C to 60°C and a stirring speed of 80r / min to 200r Stir for 2h to 10h under the condition of 1 / min, then evaporate the solvent to dryness at a temperature of 80°C to 110°C to obtain the precursor;

[0019] 3. Carbonization treatment: Under the protection of inert gas, the precursor obtained in step 2 is controlled at a heating rate of 2°C / min to 15°C / min, and the temperature is raised to 600°C to 1200°C, and the holding time is 30min to 300min to obtain a carbonized product ;

[0020] 4. Acid treatment...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the pretreatment steps described in step one are as follows: the biomass is added to an aqueous solution of potassium hydroxide with a mass fraction of 10% to 35%, the mass fraction 10%-35% sodium hydroxide aqueous solution, 10%-35% hydrochloric acid aqueous solution, 10%-35% nitric acid aqueous solution or 10%-35% high manganese In the aqueous solution of potassium acid potassium, activate at an activation temperature of 90°C to 190°C for 3h to 8h to complete the pretreatment. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 in that the biomass described in step 1 is coconut shell, corn stalk, palm shell, bagasse, cattail grass, bamboo or sawdust. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com