Triangular crawler running mechanism in tractor

A triangular crawler and walking mechanism technology, which is applied in the field of agricultural equipment, can solve the problems of not being suitable for the late stage of rice and high-stem crops, and low ground clearance, and achieve the effects of good stability of equipment, less pressure on seedlings, and narrow track width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

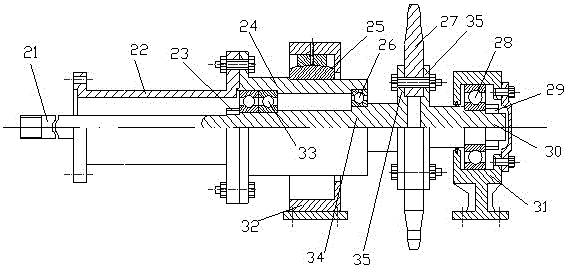

[0019] Combine Figure 1-6 Taking the application of the triangular crawler walking mechanism in the tractor as an example, the present invention will be described.

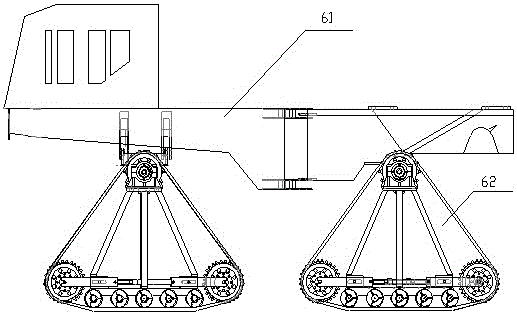

[0020] Such as figure 1 , Tractor walking device, including a rectangular frame 61 and four symmetrically arranged drive axle half shafts and four triangular crawler walking mechanisms 62, each drive axle half shaft is supported on the machine by two supporting units on the corresponding side of the frame. Frame 61, each triangular crawler walking mechanism 62 is connected to the drive axle half shaft between the inner and outer supporting units.

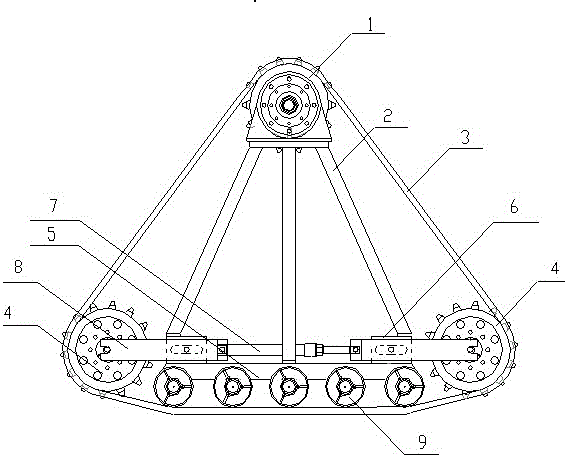

[0021] The preferred design of the above triangular crawler walking mechanism is as figure 2 , Including the driving wheel 1, the guide wheel 4, the walking wheel 9, the trapezoidal support 2 and the crawler belt 3. The driving wheel 1 is set above the trapezoidal support 2, the walking wheel 9 is set below the trapezoidal support 2, and the two guide wheels 4 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com