Method for synchronously separating effective components in liquorice

A technology for simultaneous separation of active ingredients, applied in medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, pharmaceutical formulations, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

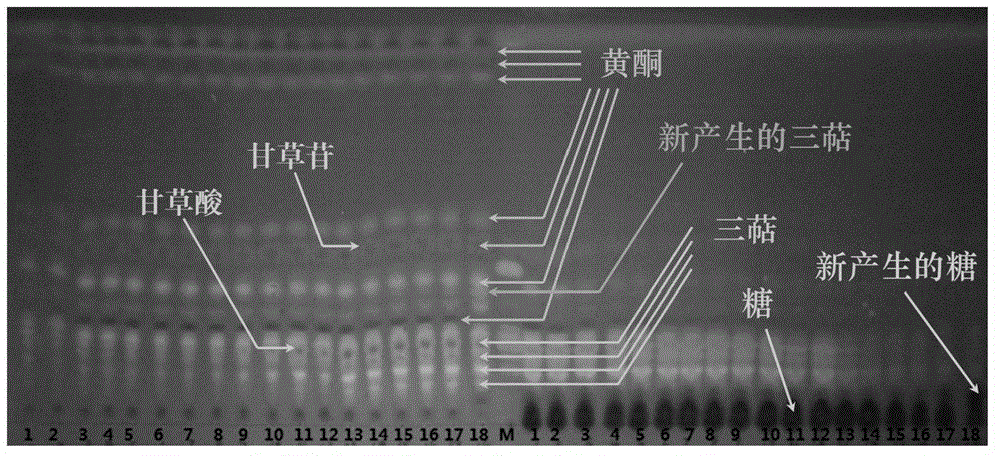

Embodiment 1

[0063] Take 100g of licorice powder, add 50wt% methanol to reflux extraction 3 times according to the ratio of material to liquid 1:10, 1:8 and 1:8, each time for 1 hour, filter, combine the extracts, recover ethanol under reduced pressure, and the specific gravity of the concentrated solution is 1.15 ( 20°C), add water-saturated n-butanol at a ratio of 1:1, add sodium hydroxide to adjust the pH of the system to 7.0, shake well and extract once, flavonoids are in the n-butanol layer, triterpenoids and sugars are in the water layer, separated the n-butanol layer, recovered the solvent under reduced pressure, and vacuum-dried (60°C) to constant weight to obtain 2.55 grams of crude licorice flavonoids, of which the total flavonoid content of licorice root was 80.75%, and the content of liquiritin was 35.56%. Add water-saturated n-butanol solution at a ratio of 1:1, add hydrochloric acid to adjust the pH of the system to 3.0, shake well and extract once, the triterpenoids are in th...

Embodiment 2

[0065] Take 100g of licorice powder, add 20wt% ethanol to reflux extraction 3 times according to the ratio of material to liquid 1:10, 1:8 and 1:8, each time for 1 hour, filter, combine the extracts, recover ethanol under reduced pressure, and the specific gravity of the concentrated solution is 1.15 ( 20°C), add water-saturated n-butanol at a ratio of 1:1, add sodium hydroxide to adjust the pH of the system to 5.5, shake well and extract once, flavonoids are in the n-butanol layer, triterpenoids and sugars are in the water layer, separated the n-butanol layer, recovered the solvent under reduced pressure, and vacuum-dried (60°C) to constant weight to obtain 3.05 grams of crude licorice flavonoids, of which the total flavonoid content of licorice root was 54.10%, and the content of liquiritin was 22.95%. Add water-saturated n-butanol solution at a ratio of 1:1, add hydrochloric acid to adjust the pH of the system to 4.0, shake well and extract once, the triterpenoids are in the...

Embodiment 3

[0067] Take 100g of licorice powder, add 20wt% ethanol sodium hydroxide mixture (pH10) according to the ratio of material to liquid 1:10, 1:8 and 1:8, reflux extraction 3 times, each time for 1 hour, filter, combine the extracts, and decompress Recover ethanol, the specific gravity of the concentrated solution is 1.15 (20°C), add water-saturated n-butanol at a ratio of 1:1, add sodium hydroxide to adjust the pH of the system to 7.0, shake well and extract once, the flavonoids are in the n-butanol layer, three The terpenoids and carbohydrates were in the water layer, and the n-butanol layer was separated. After the solvent was recovered under reduced pressure, it was vacuum-dried (60°C) to constant weight to obtain 2.70 g of crude licorice flavonoids, of which the total flavonoid content of licorice was 85.42%. The content of glycosides is 37.55%; add water-saturated n-butanol solution to the water layer at a ratio of 1:1, add hydrochloric acid to adjust the system 3.0, shake we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com