Transformer Fabrication Method for Floating Filament Modulator in Microwave Power Module

A microwave power module and modulator technology, applied in inductor/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problem of not satisfying transformers, and achieve the effect of simplifying design difficulty, ensuring safety isolation, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples.

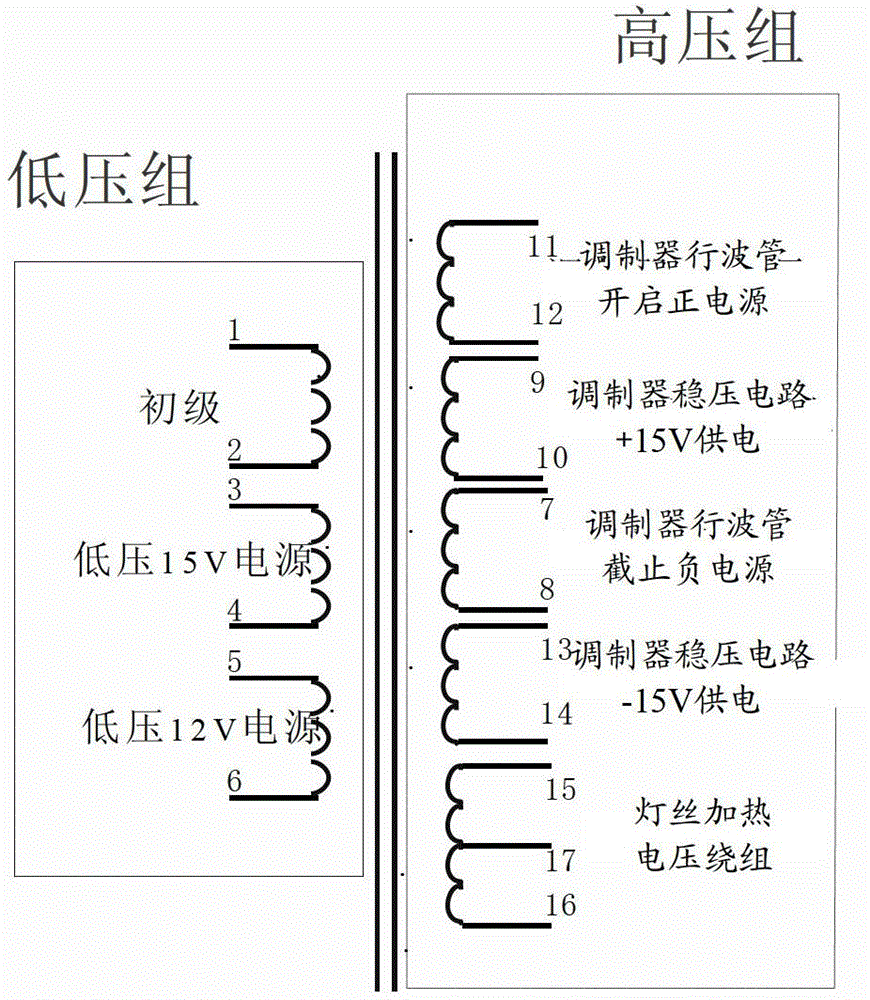

[0040] The invention provides a manufacturing method for a transformer used in a floating filament modulator in a microwave power module. The transformer includes a set of primary windings and 7 sets of secondary windings, and the 7 sets of secondary windings are divided into a high-voltage side and a low-voltage side;

[0041] The high voltage side consists of:

[0042] The modulator TWT turns on the positive power supply winding;

[0043] The modulator traveling wave tube cuts off the negative power supply winding;

[0044] Modulator voltage regulator circuit +15V power supply winding;

[0045] Modulator voltage regulator circuit -15V power supply winding;

[0046] Filament heating voltage winding;

[0047] The low pressure side consists of:

[0048] Low voltage 15V power winding;

[0049] Low voltage 12V power winding.

[0050] The present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com