Decoration component, clock component, and manufacturing methods thereof

A technology for decorative parts and a manufacturing method, applied in the field of decorative parts, can solve the problems of unstable additional voltage, uneven color, and poor appearance in appearance, and achieve the effect of preventing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

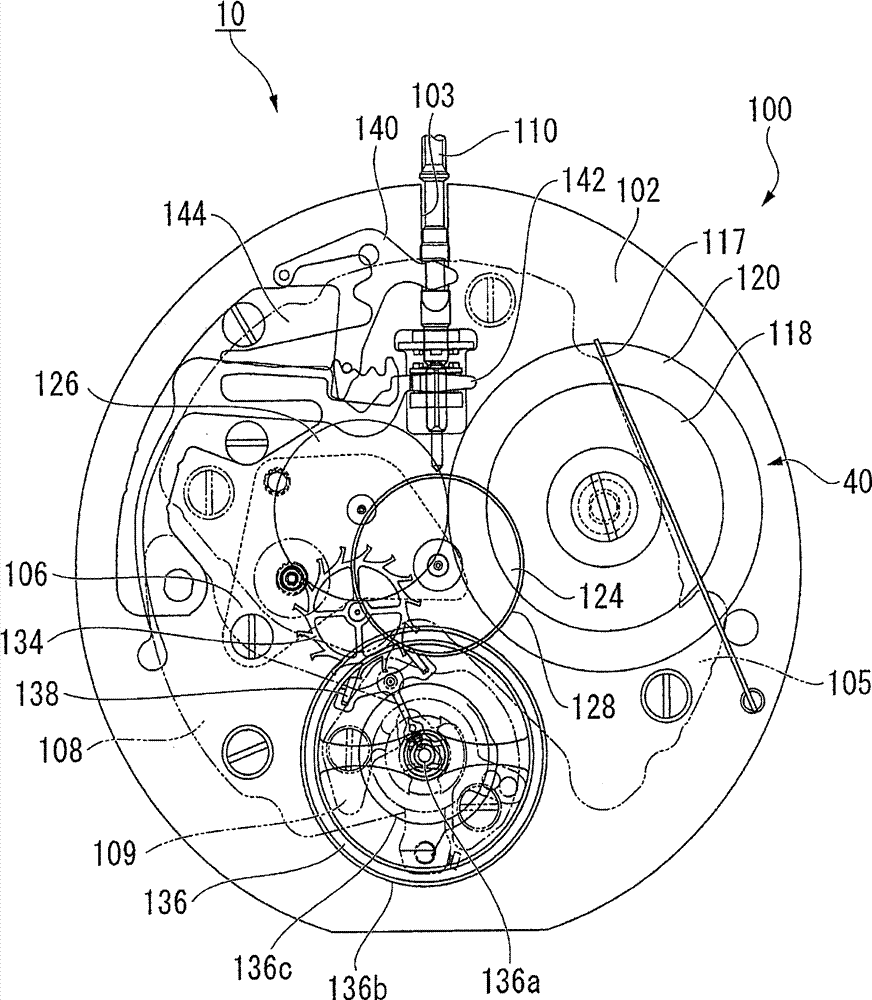

[0070] Next, based on figure 1 , figure 2 , image 3 A timepiece provided with an oscillating weight as a decorative part according to an embodiment of the present invention will be described.

[0071] figure 1 It is a plan view of the movement 100 viewed from the front side with the self-winding mechanism removed, figure 2 This is a schematic diagram of the automatic winding mechanism.

[0072] Such as figure 1 , figure 2 As shown, the self-winding wristwatch 10 incorporating the decorative parts according to the present invention (such as the pendulum 160 described later) is composed of a movement 100 and an unillustrated case for accommodating the movement 100. The unillustrated dial plate Installed on the movement 100. The movement 100 includes a bottom plate 101 constituting a base plate, a first bridge 105 , a second bridge 106 , a balance bridge 108 , and a fork bridge 109 . The second splint 106 is disposed between the first splint 105 and the bottom plat...

no. 2 approach

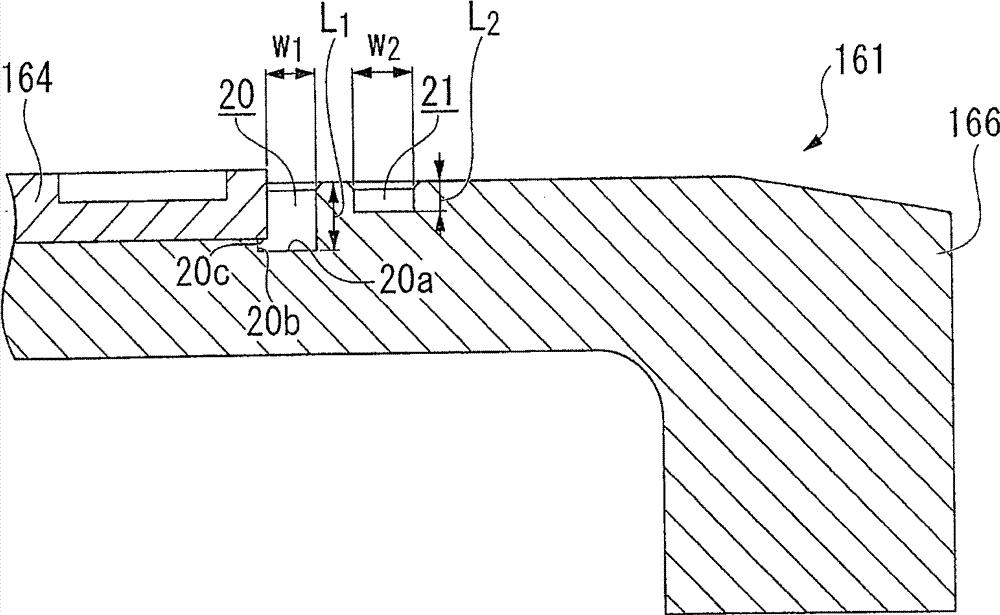

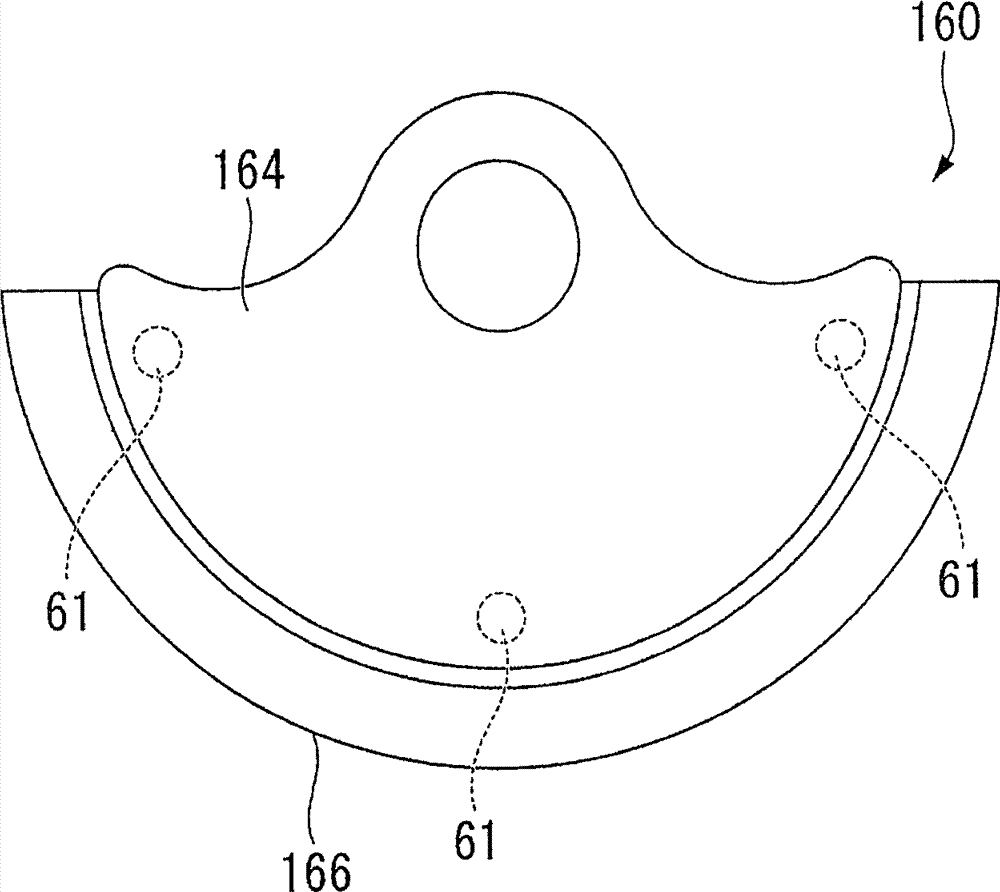

[0114] Next, quote figure 1 , figure 2 , image 3 and based on Figure 10 A second embodiment of the present invention will be described. In addition, the same code|symbol is attached|subjected and demonstrated about the same aspect as 1st Embodiment.

[0115] Figure 10 is a longitudinal section of the pendulum 161 in the second embodiment.

[0116] In this second embodiment, a self-winding wristwatch 10 has a movement 100, and a wheel train called a watch wheel train, and an escapement / speed regulating device for controlling the rotation of the watch wheel train are incorporated on the front side of the movement 100. 40, automatic winding mechanism 60, etc., and that the pendulum 160 of the automatic winding mechanism 60 has a ball bearing 162, a pendulum body 164, and a rotating weight 166. The structure of the timepiece is the same as that of the first embodiment described above. In addition, the pendulum body 164 is formed in a substantially fan-shaped plan view, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com