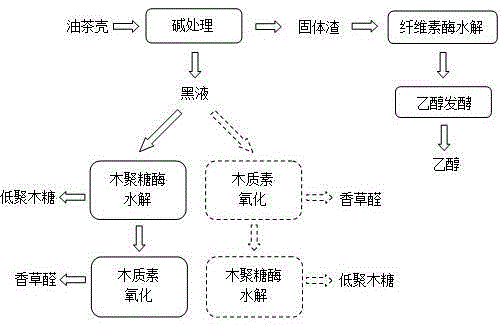

A kind of comprehensive utilization method of camellia oleifera shell

A technology of camellia oleifera shell and solid-liquid separation, applied in the direction of microorganism-based methods, biochemical equipment and methods, separation/purification of carbonyl compounds, etc., to achieve the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

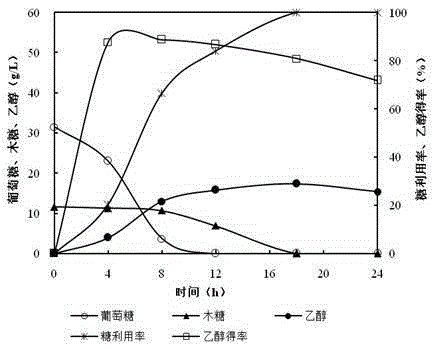

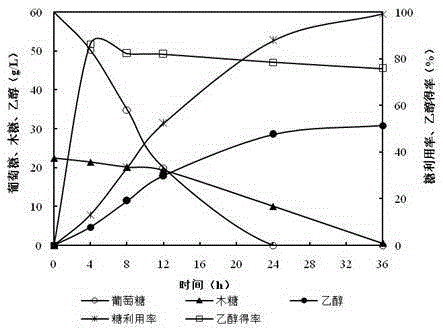

[0040] Example 2: Enzymatic hydrolyzate fermentation to prepare fuel ethanol

[0041]The solid residue after the Camellia oleifera shell alkali pretreatment is enzymatically hydrolyzed with cellulase, and the obtained monosaccharide is used for ethanol fermentation. Glucose and xylose were contained in the enzymatic hydrolyzate, and ethanol fermentation was carried out by using a strain of Pichia stipitis CBS5776 capable of utilizing glucose and xylose. The enzymatic hydrolyzate fermentation includes direct ethanol fermentation of the enzymatic hydrolyzate and ethanol fermentation after the enzymatic hydrolyzate is concentrated by 1 times. Fermentation medium composition: 5g (NH 4 ) 2 SO 4 , 3gKH 2 PO 4 , 0.5gMgSO 4 ·7H 2 O, 30 mg EDTA, 9 mg ZnSO 4 ·7H 2 O, 2mgMnCl 2 ·2H 2 O, 0.6 mg CoCl 2 ·6H 2 O, 0.6 mg CuSO 4 ·5H 2 O, 0.8mgNa 2 MoO 4 ·H 2 O, 9 mg CaCl 2 ·2H 2 O, 6 mg FeSO 4 ·7H 2 O, 2mgH 3 BO 3 , 0.2mgKI. Adjust pH to 6.0 with sodium hydroxide. The...

Embodiment 3

[0050] Example 3: Separation of xylan and lignin by adjusting pH

[0051] Take 30mL of the black liquor after the best pretreatment (Example 1) in a 50mL centrifuge tube, add 72% sulfuric acid to adjust the pH value of the black liquor to about 1, 2, 3, 4, 5, 6, and 7 respectively. . After equilibration, it was centrifuged at 10000 r / min for 5 min to carry out solid-liquid separation, and the solid precipitate and supernatant were collected respectively, and the volume of the supernatant was measured for use.

[0052] Take 10 mL of the supernatant into a 50 mL conical flask, add 10 mL of 8% sulfuric acid, seal it with parafilm, react at 121 °C for 60 min, take it out after cooling, use G 3 The filtrate was collected and the volume was recorded. Liquid part: mainly analyze the content of acid-soluble / acid-insoluble lignin and xylan content.

[0053] The obtained solid precipitate was washed with distilled water and the volume was adjusted to 25 mL. Take 10 mL of the well-mi...

Embodiment 4

[0055] Example 4: Preparation of the chemical vanillin

[0056] The chemical vanillin is prepared by the method of pretreating lignin in black liquor by alkaline oxidation of Camellia oleifera. In the process proposed by the present invention, xylan and lignin should be used as a whole, but it is unknown whether to first oxidatively degrade lignin to prepare vanillin, then enzymatically hydrolyze xylan to prepare xylo-oligosaccharide, or firstly enzymatically hydrolyze xylan to prepare Xylo-oligosaccharide and lignin oxidation to produce vanillin? Therefore, the results of the preparation of vanillin by oxidation of different samples under alkaline conditions (sodium hydroxide concentration of 2 mol / L, 170 °C, 2 h) are shown in Table 4.

[0057] Table 4 Compositional analysis of different sample preparation chemicals

[0058]

[0059] Note: lignin oxidation conditions: 30mL black liquor, 2.0mol / LNaOH, 0.98gCuO, 170℃, 2h. Xylanase hydrolysis conditions: xylanase dosage 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com