High-temperature-resistant powder paint

A technology of powder coatings and high-temperature-resistant pigments, which is applied in the direction of powder coatings, polyester coatings, epoxy resin coatings, etc., and can solve the problems of high cost and popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

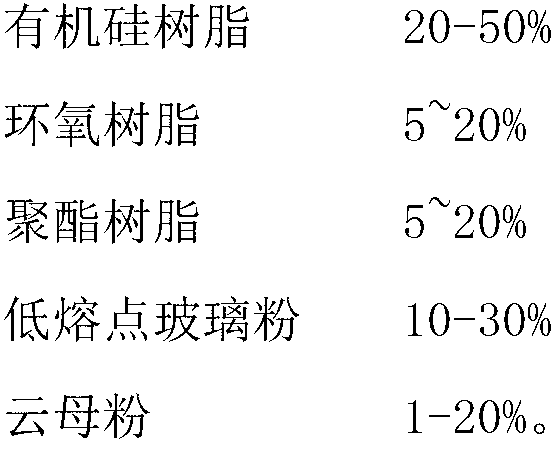

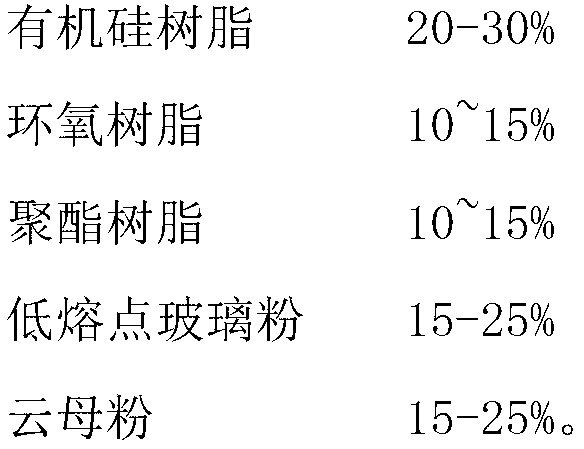

Method used

Image

Examples

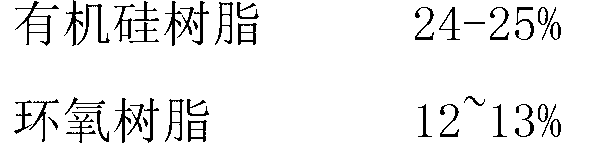

Embodiment 1

[0027] Accurately weigh the material according to the formula composition shown in Table 1, put it in a high-speed mixer and mix it for 6-8 minutes; extrude the material with an extruder at a temperature of 90-100°C after mixing; cool and crush the extruded material with a pulverizer Crushed into powder particles with an average particle size of 30-33 microns; then sieved with a 180-mesh sieve, and finally packaged into a finished product.

[0028] Table 1. Curing at room temperature and high temperature resistance (600°C) low-cost black sand texture powder coating formula (weight percentage)

[0029] material

%

Silicone resin

25

epoxy resin

13

polyester resin

13

Low melting point glass powder

20

Manganese black

8

Mica powder

19

Sanding agent

0.3

hardening agent

0.7

leveling agent

1

[0030] The powder coating obtained according to the above examples adopts t...

Embodiment 2

[0034] Accurately weigh the material according to the formula composition shown in Table 3, place it in a high-speed mixer and mix it for 6-8 minutes; extrude the material with an extruder at a temperature of 90-100°C after mixing; cool and crush the extruded material with a pulverizer Crushed into powder particles with an average particle size of 30-33 microns; then sieved with a 180-mesh sieve, and finally packaged into a finished product.

[0035] Table 3. Curing at room temperature and high temperature resistance (600°C) low-cost black sand texture powder coating formula (weight percent)

[0036] material

%

Silicone resin

25

epoxy resin

10

polyester resin

15

Low melting point glass powder

20

Manganese black

8

[0037] Mica powder

20

Sanding agent

0.3

hardening agent

0.7

leveling agent

1

[0038] The powder coating obtained according to the above...

Embodiment 3

[0042] Accurately weigh the material according to the formula composition shown in Table 5, place it in a high-speed mixer and mix it for 6-8 minutes; extrude the material with an extruder at a temperature of 90-100°C after mixing; cool and crush the extruded material with a pulverizer Crushed into powder particles with an average particle size of 30-33 microns; then sieved with a 180-mesh sieve, and finally packaged into a finished product.

[0043] Table 5 Curing at room temperature and high temperature resistance (600°C) low-cost black sand texture powder coating formula (weight percent)

[0044] material

%

Silicone resin

30

epoxy resin

10

10

Low melting point glass powder

20

Manganese black

8

Mica powder

15

Sanding agent

0.3

hardening agent

0.7

leveling agent

1

[0045] The powder coating obtained according to the above examples adopts the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com