pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire edges, tire sidewalls, etc., can solve problems such as breakage, and achieve the effects of easing pressure, reducing tire weight, and maintaining zero-pressure driving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

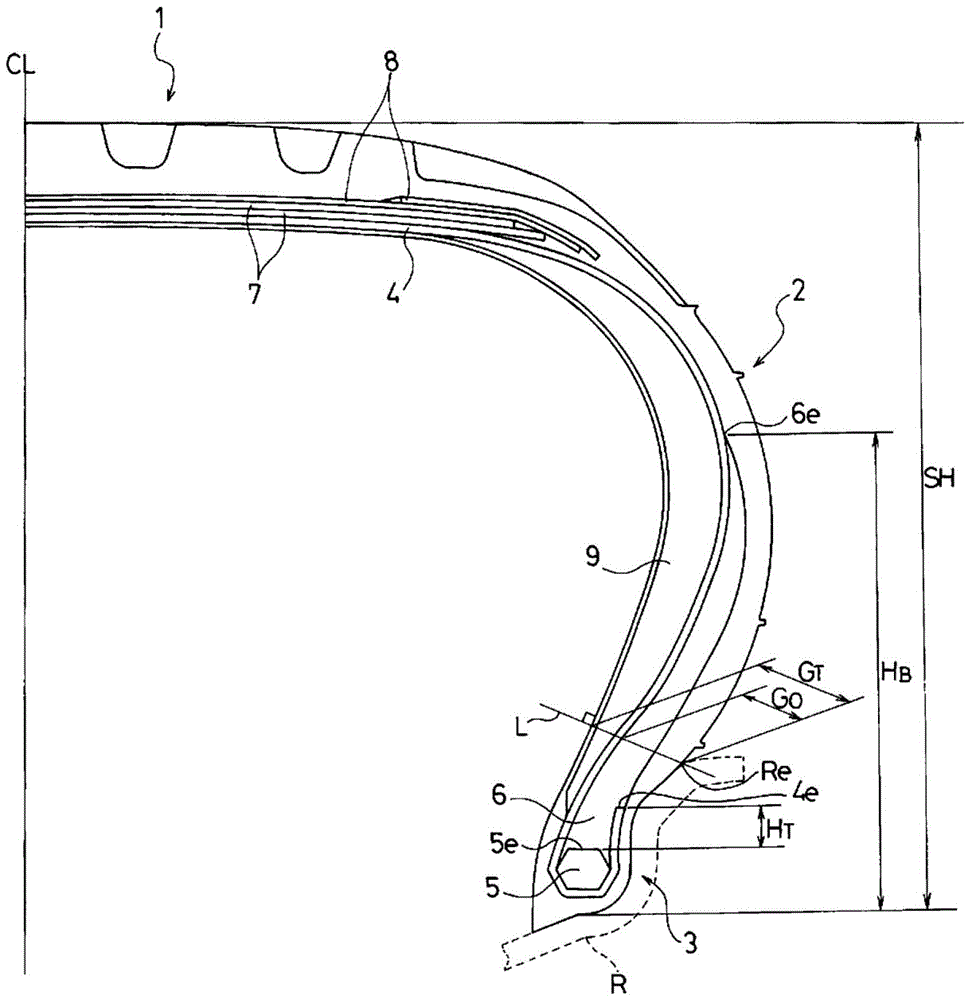

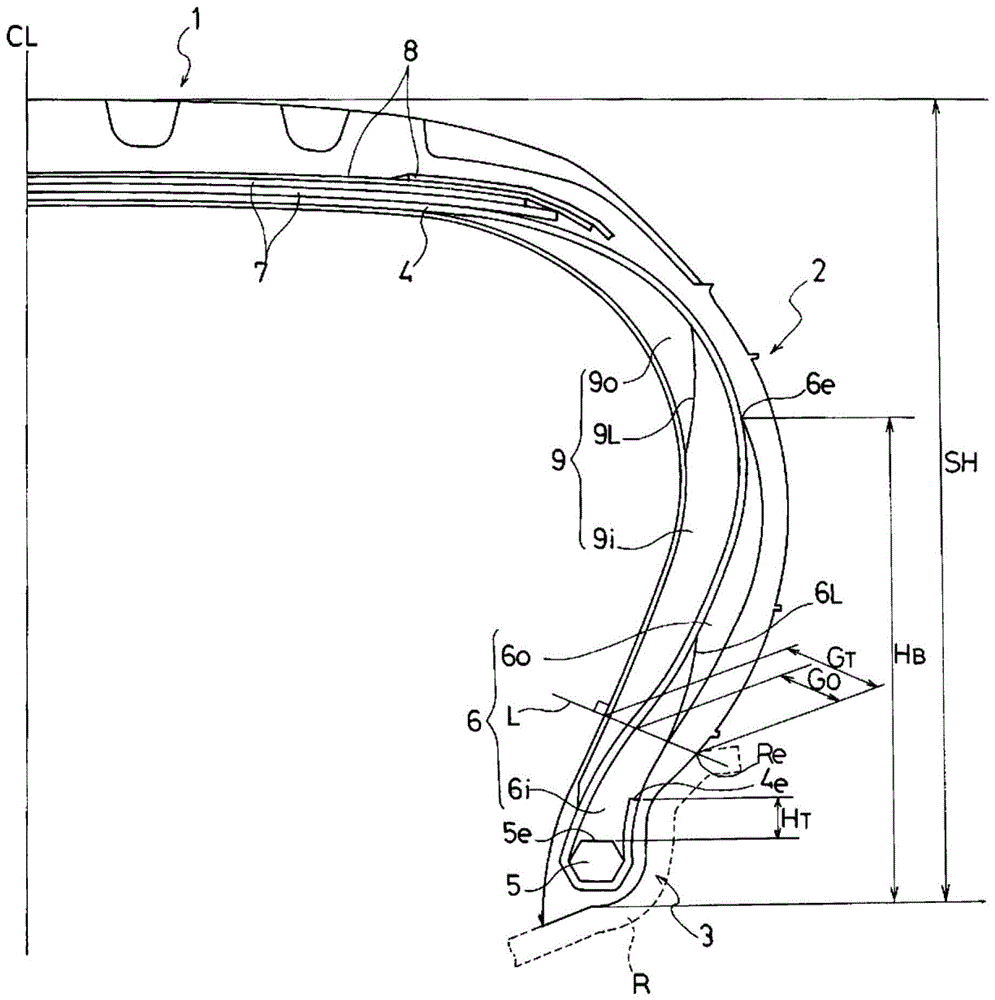

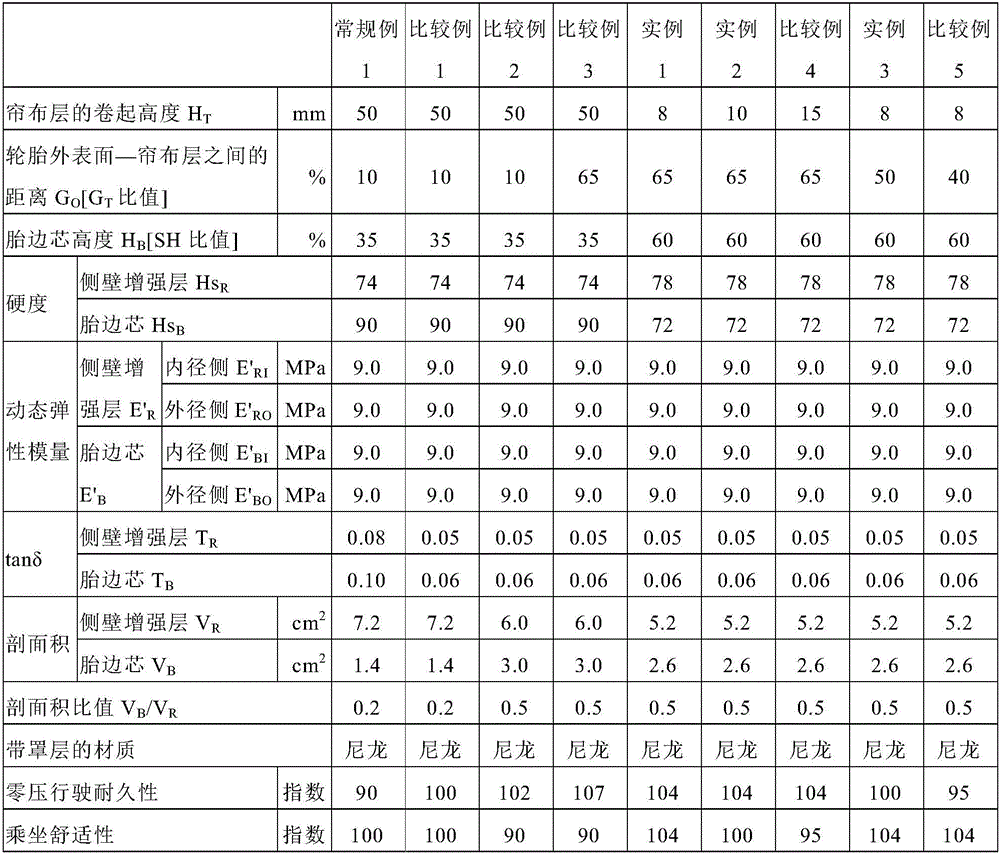

[0049] In pneumatic tires with tire size 235 / 50R18, press figure 2 Unify the basic tire section structure, and set the ply ply rolling height H as shown in Tables 1 to 5 T , on the imaginary line L relative to the total thickness G of the side wall T The distance G from the outer surface of the tire to the ply O The ratio of the bead filler height H relative to the tire section height SH B The ratio of the ratio, the hardness Hs of the rubber composition constituting the bead core at 20°C B , The hardness Hs of the rubber composition constituting the side wall reinforcement layer at 20°C R , The dynamic elastic modulus E' of the rubber composition constituting the bead filler at 60°C B (inner diameter side E' BI and outer diameter side E' BO ), the dynamic elastic modulus E' of the rubber composition constituting the sidewall reinforcement layer at 60°C R (inner diameter side E' RI and outer diameter side E' RO ), the tanδ value T of the rubber composition constituti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com