Composite hard carbon negative electrode material, and preparation method and application thereof

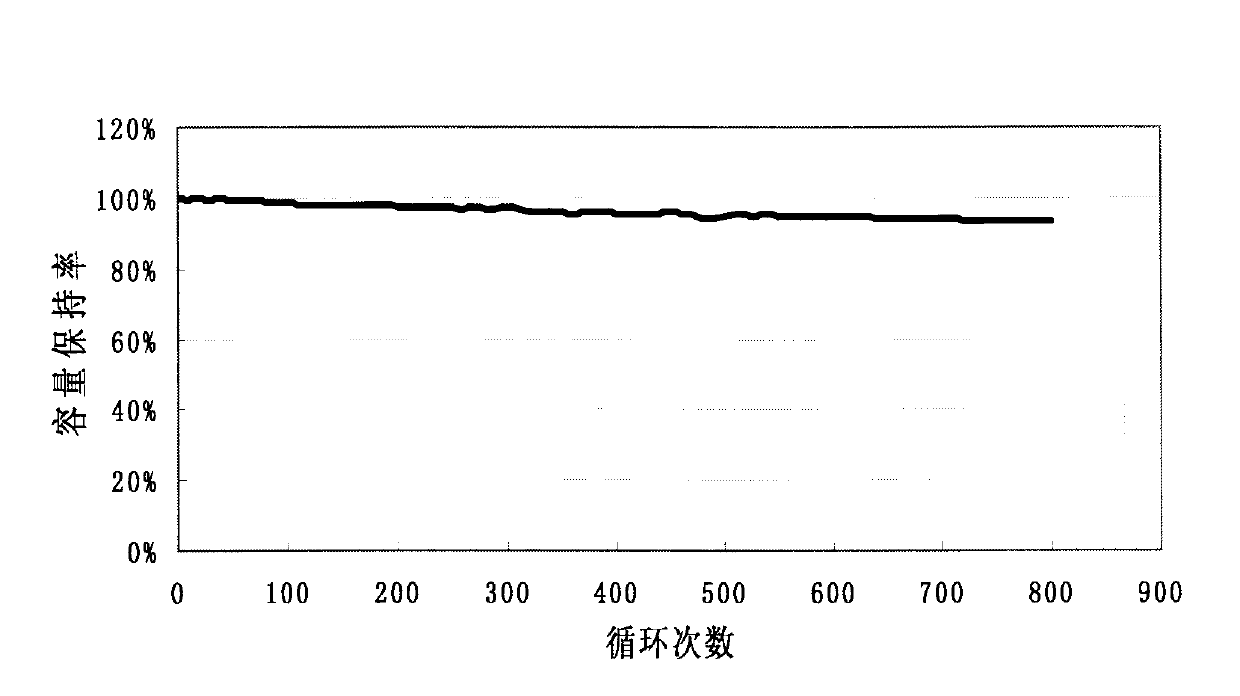

A negative electrode material, hard carbon technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of difficult commercialization, complicated preparation process, high manufacturing cost, etc., and achieve high-current charge and discharge performance and good cycle performance. Good chemical performance and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

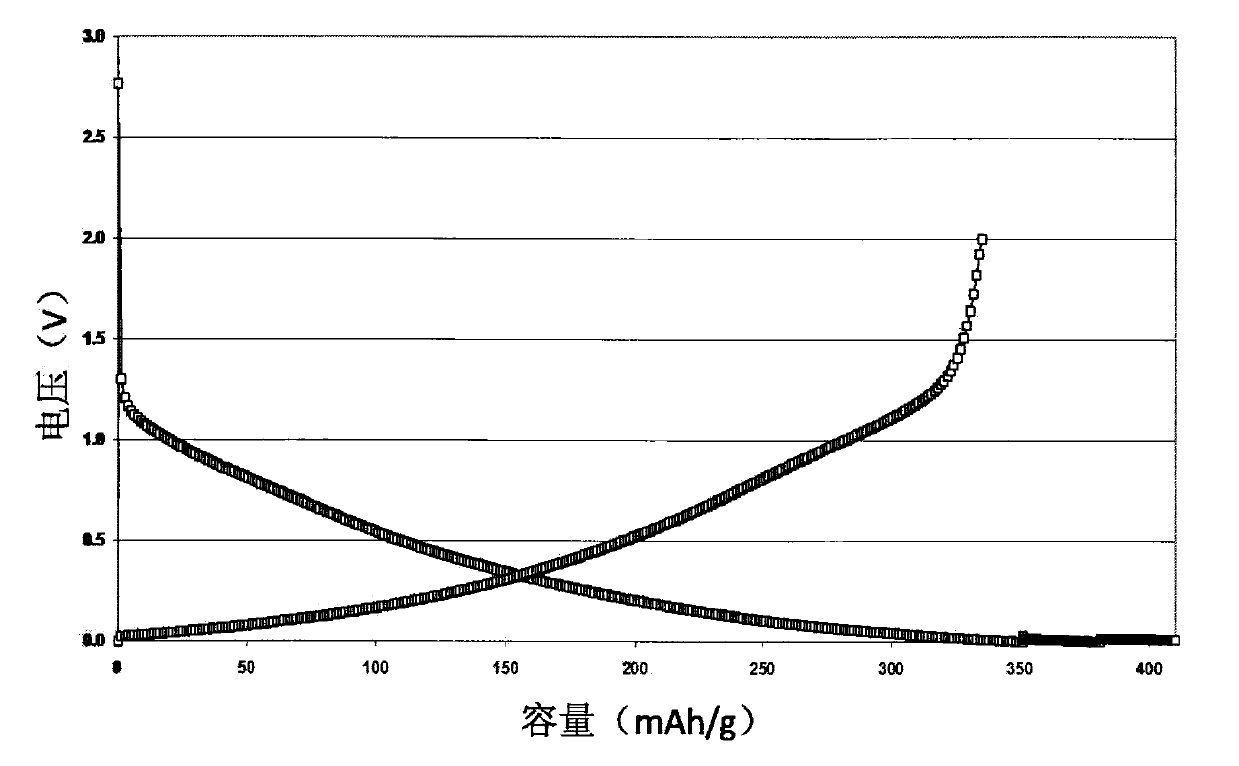

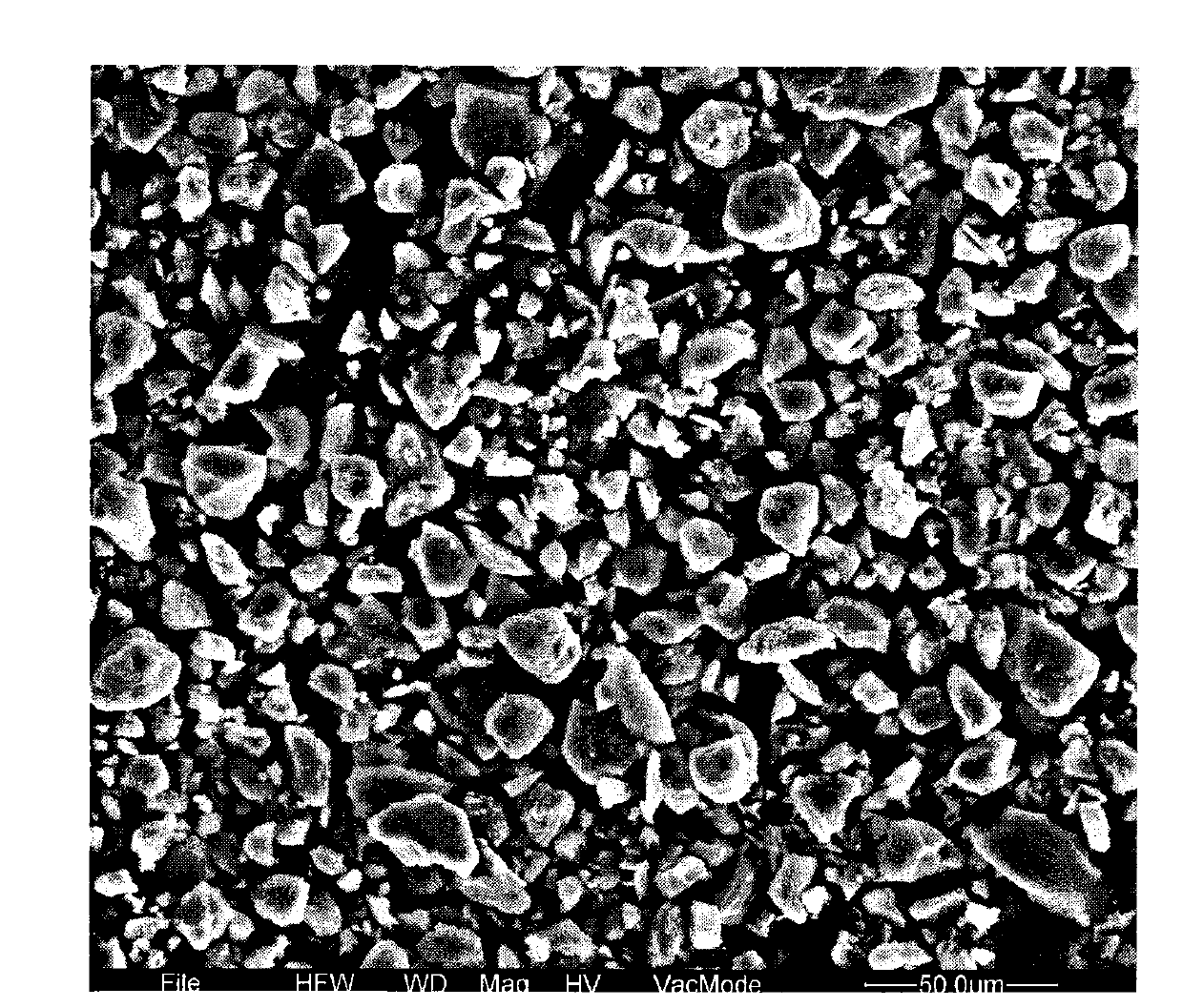

Embodiment 1

[0034] ①Coal tar pitch and benzaldehyde cross-linking agent were cross-linked and polymerized at 120°C for 2 hours at a mass ratio of 2:1 to obtain a cross-linked body; ②The cross-linked body was cured at 300°C for 4 hours in an inert atmosphere, and then Pulverized by a pulverizer at a speed of 1000 rpm, passed through a 60-mesh sieve, and pre-carbonized at 600 °C for 16 hours in an inert atmosphere to obtain a carbon precursor; ③ Pulverized by a pulverizer at a speed of 2000 rpm, the frequency Classified at 105Hz to obtain carbon precursor particles with a volume average particle diameter D50 of 8.3 μm, and carbonized particles were obtained by carbonization and heat treatment at 1100°C for 18 hours in an inert atmosphere; ④ carbonized particles were mixed with natural graphite at a mass ratio of 4:1 for 1.5 hours , to obtain a composite hard carbon negative electrode material; wherein, the volume average particle diameter D50 of the natural graphite is 17 μm, and the tap den...

Embodiment 2

[0036]① Coal tar pitch and benzaldehyde cross-linking agent were subjected to cross-linking polymerization reaction at 120°C for 2 hours at a mass ratio of 5:2 to obtain a cross-linked body; ②The cross-linked body was cured at 500°C for 2 hours in an inert atmosphere, and then Pulverized by a pulverizer at a speed of 800 rpm, passed through a 60-mesh sieve, and pre-carbonized at 600°C for 20 hours in an inert atmosphere to obtain a carbon precursor; ③ Pulverized by a pulverizer at a speed of 5000 rpm 90Hz classification to obtain carbon precursor particles with a volume average particle diameter D50 of 12.9 μm, and carbonized particles at a high temperature of 1100°C for 24 hours in an inert atmosphere to obtain carbonized particles; ④ Mix carbonized particles and natural graphite at a mass ratio of 7:3 for 3 hours , to obtain a composite hard carbon negative electrode material; wherein, the volume average particle diameter D50 of the natural graphite is 23 μm, and the tap dens...

Embodiment 3

[0038] ①Petroleum pitch and benzaldehyde cross-linking agent were cross-linked and polymerized at 100°C for 4 hours at a mass ratio of 10:3 to obtain a cross-linked body; ②The cross-linked body was cured at 500°C for 2 hours in an inert atmosphere, and then subjected to Pulverize with a pulverizer at 1000 rpm, pass through a 60-mesh sieve, and pre-carbonize at 650°C for 8 hours in an inert atmosphere to obtain a carbon precursor; ③ Pulverize with a pulverizer at a speed of 8000 rpm. Classification to obtain carbon precursor particles with a volume average particle diameter D50 of 8.3 μm, and carbonization and heat treatment at 800 ° C for 24 hours in an inert atmosphere; ④ Mix carbonized particles and natural graphite at a mass ratio of 1:1 for 2 hours to obtain a composite Hard carbon negative electrode material; wherein, the volume average particle diameter D50 of the natural graphite is 16 μm, and the tap density is 1.06 g / cm 3 , specific surface area 2.3m 2 / g, true densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com