Preparation method of indole-modified carbon sulfur-coated and compound lithium sulfur battery anode material

A lithium-sulfur battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable battery high rate performance, poor electrode mechanical stability, large volume changes, etc., to improve electrochemical power. chemical properties, reduction of electrode polarization, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

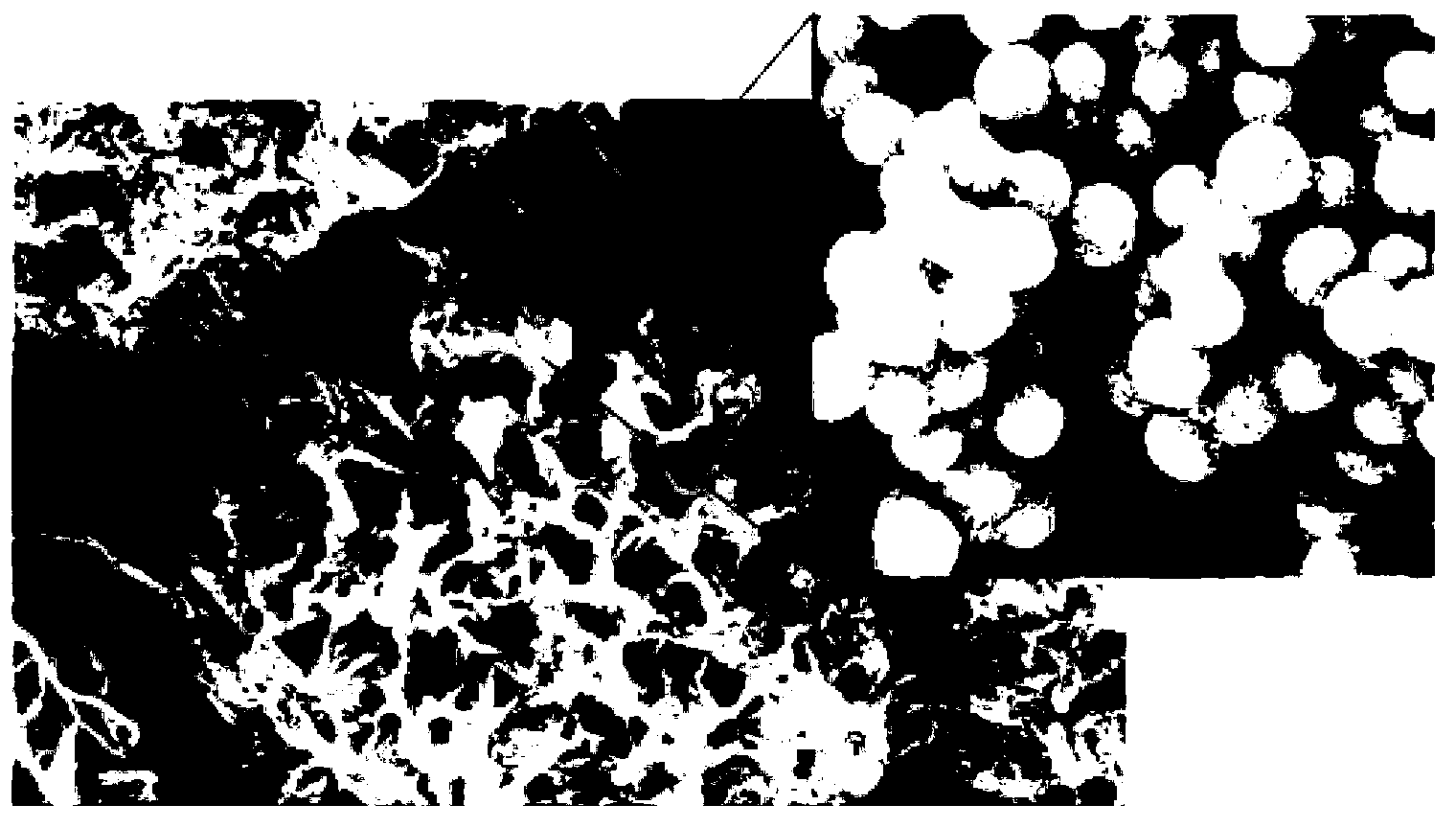

[0026] Example 1: Preparation of hollow carbon sphere precursor

[0027] Dissolve 2 g of glucose in 100 mL of deionized water, stir and dissolve, and then introduce it into a reactor with a total capacity of 150 mL. Then add 10 g of spherical aluminum powder with a purity of 99.99% and a particle size of 1 to 5 microns, and seal the reaction kettle after adding magnets. The reaction kettle was placed in an oil bath at 250° C., and the reaction kettle was taken out after 2 hours of magnetic stirring. After the reactor was cooled to room temperature, the reactor was opened and centrifuged to obtain a brown or black solid powder sample (hollow carbon sphere precursor).

Embodiment 2

[0028] Example 2: Precursor carbonization

[0029] Dissolve 5 g of sucrose in 100 mL of deionized water, stir and dissolve, and then introduce it into a reactor with a total capacity of 150 mL. Then add 10 g of spherical aluminum powder with a purity of 99.99% and a particle size of 5 to 10 microns, and seal the reaction kettle after adding magnets. The reaction kettle was placed in an oil bath at 250° C., and the reaction kettle was taken out after 4 hours of magnetic stirring. After the reaction kettle is cooled to room temperature, open the reaction kettle, take out the filtered product, the product is in the form of brown or black solid powder, washed with water and ethanol, centrifuged, dried in vacuum at 40°C and heated to 500°C under the protection of nitrogen atmosphere, constant temperature Carbonize for 5 hours.

Embodiment 3

[0030] Example 3: Preparation of hollow carbon spheres

[0031] 10 g of starch was dissolved in 100 mL of deionized water, stirred and dissolved, and introduced into a reactor with a total capacity of 150 mL. Then add 10 g of spherical aluminum powder with a purity of 99.99% and a particle size of 5 to 10 microns, and seal the reaction kettle after adding magnets. The reaction kettle was placed in an oil bath at 250° C., and the reaction kettle was taken out after 8 hours of magnetic stirring. After the reaction kettle is cooled to room temperature, open the reaction kettle, take out the filtered product, the product state is brown or black solid powder, wash with water and ethanol respectively, and centrifuge. After vacuum drying at 40 °C in a tube furnace, the temperature was raised to 600 °C under the protection of nitrogen atmosphere, and carbonized at constant temperature for 3 hours. After cooling to room temperature, the sample was taken out, and treated with 1 wt% di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com