Cooling method for processing indoor parts

A cooling method and a technology of a processing chamber, which are applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of lower heat transfer efficiency of the mounting table, poor return on investment, and rising costs, and achieve the goal of suppressing the transfer efficiency Effect of lowering, rapid cooling, and suppression of rise in atmospheric temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

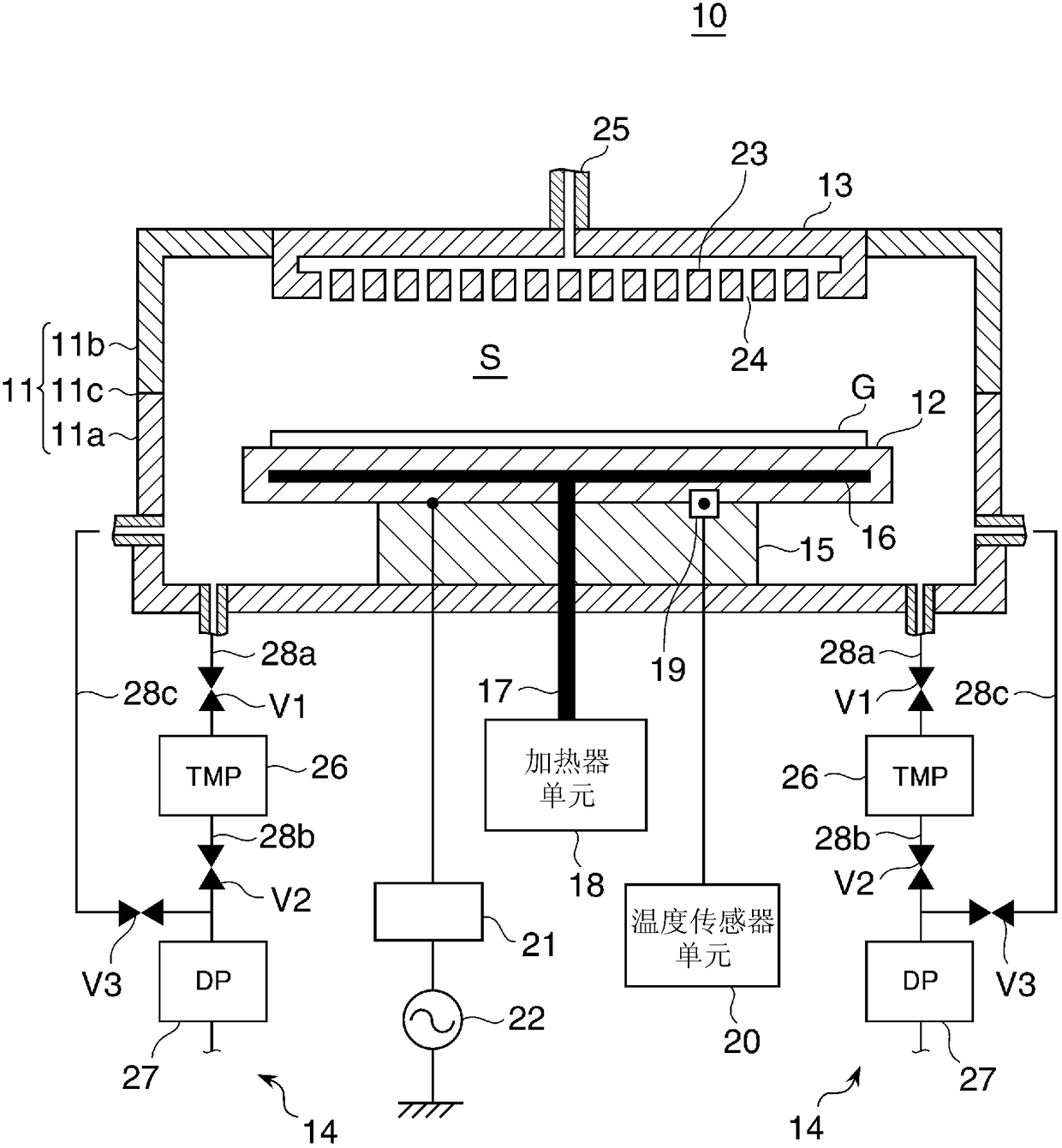

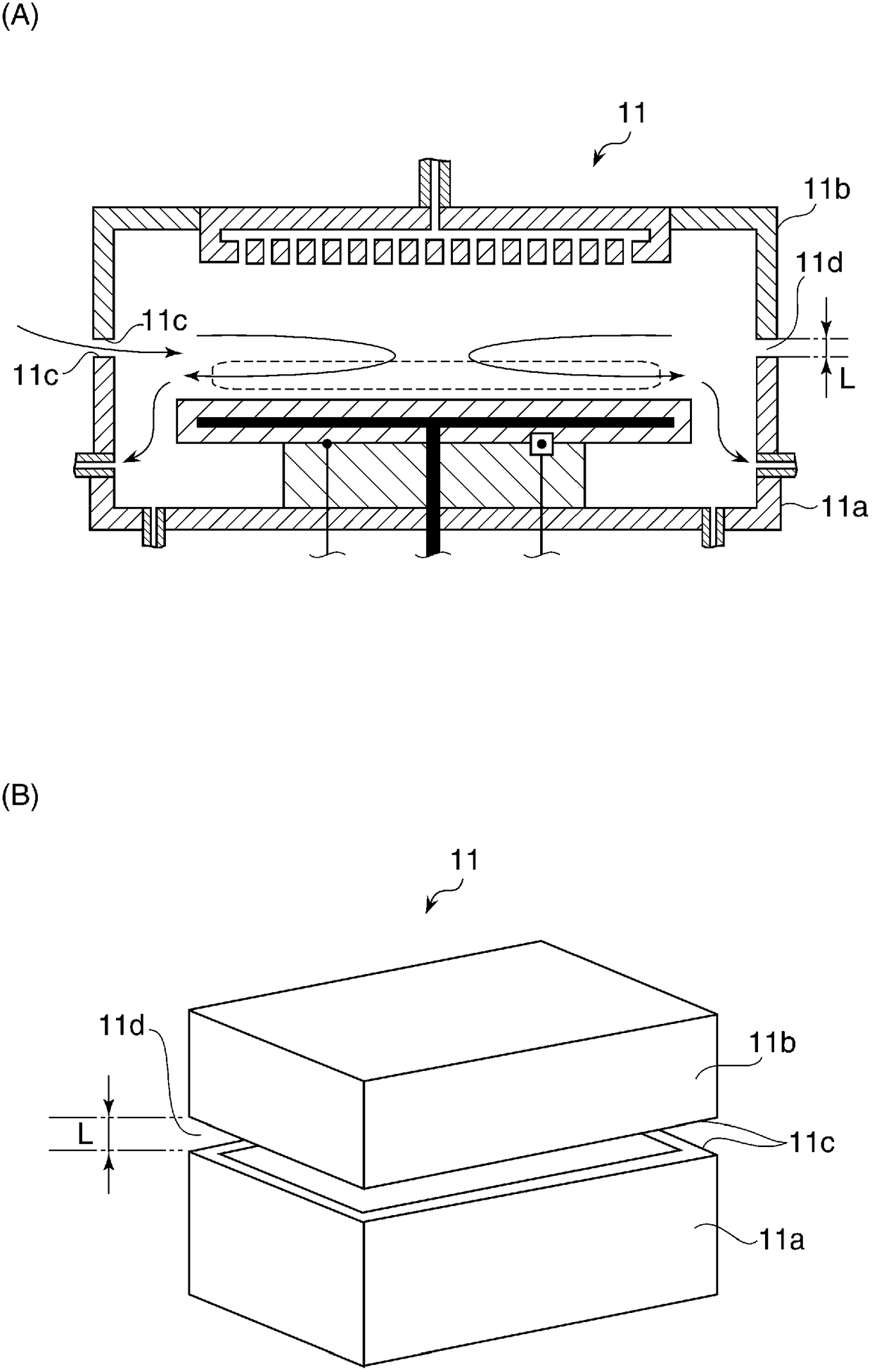

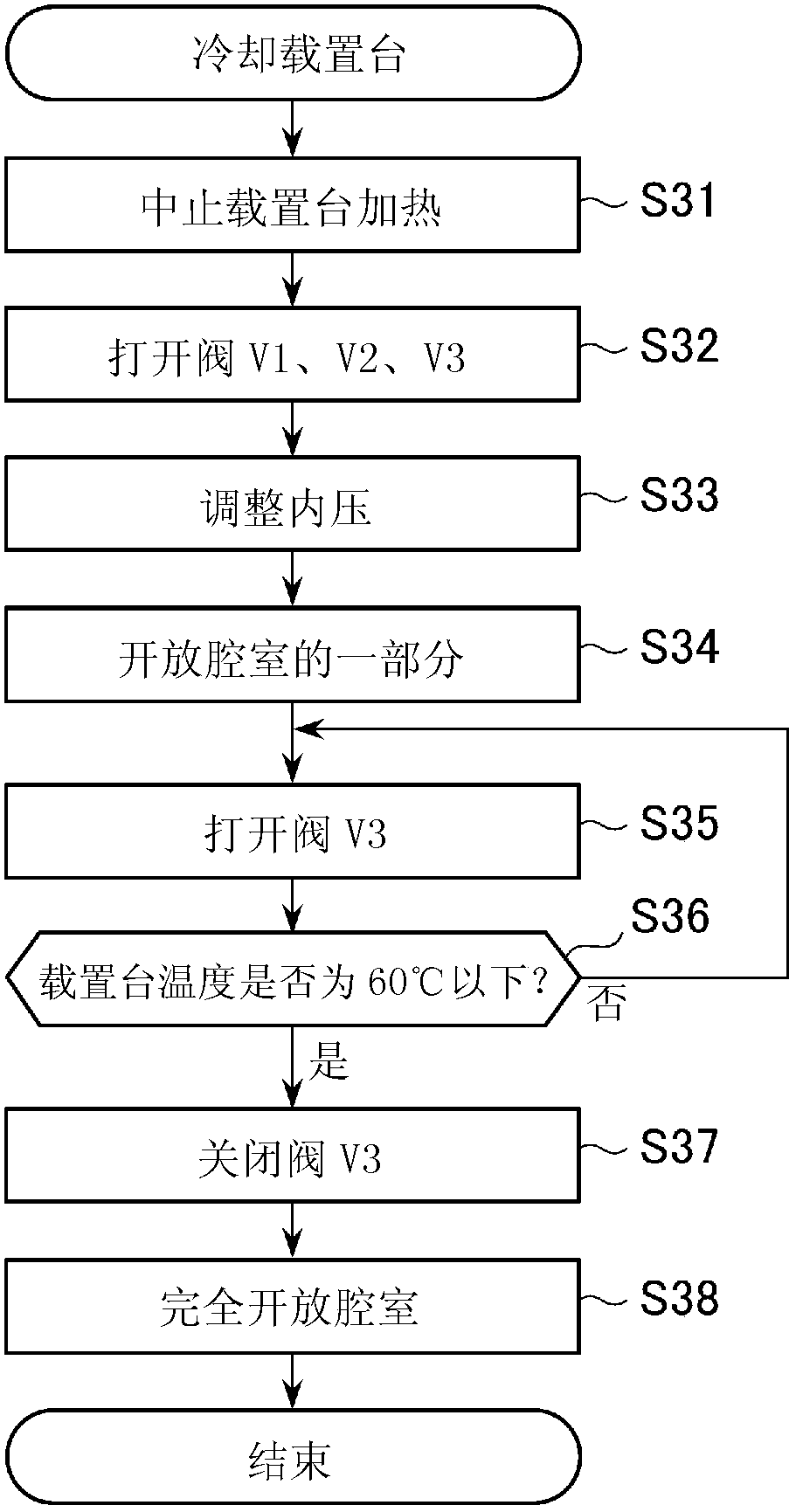

[0076] First, when the dry etching process is performed in the substrate processing apparatus 10, the stage 12 is heated to 260° C. by the heater 16, and then the image 3 In the cooling treatment of the mounting table, the cooling time of the mounting table 12 to 60° C. was measured, and it was found that only 16 hours were needed (Example). In addition, in the Example, the opening amount L of the opening part 11d was set to 45 mm.

[0077] On the other hand, similarly to the embodiment, in the substrate processing apparatus 10, the stage 12 is heated to 260° C. by the heater 16, and after that, the atmosphere is introduced into the chamber 11, and the chamber 11 is not exhausted. The chamber 11 was placed in the air without separating the lid portion 11b from the base portion 11a, and the cooling time for the mounting table 12 to 60° C. was measured, and it was found that it took 48 hours (comparative example).

[0078] Therefore, it can be seen that compared with the case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com