Buffer device for super-heavy-load tensile tester

A tensile testing machine, ultra-large load technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of low reliability, high manufacturing cost, complicated control, etc. The effect of smooth buffering and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

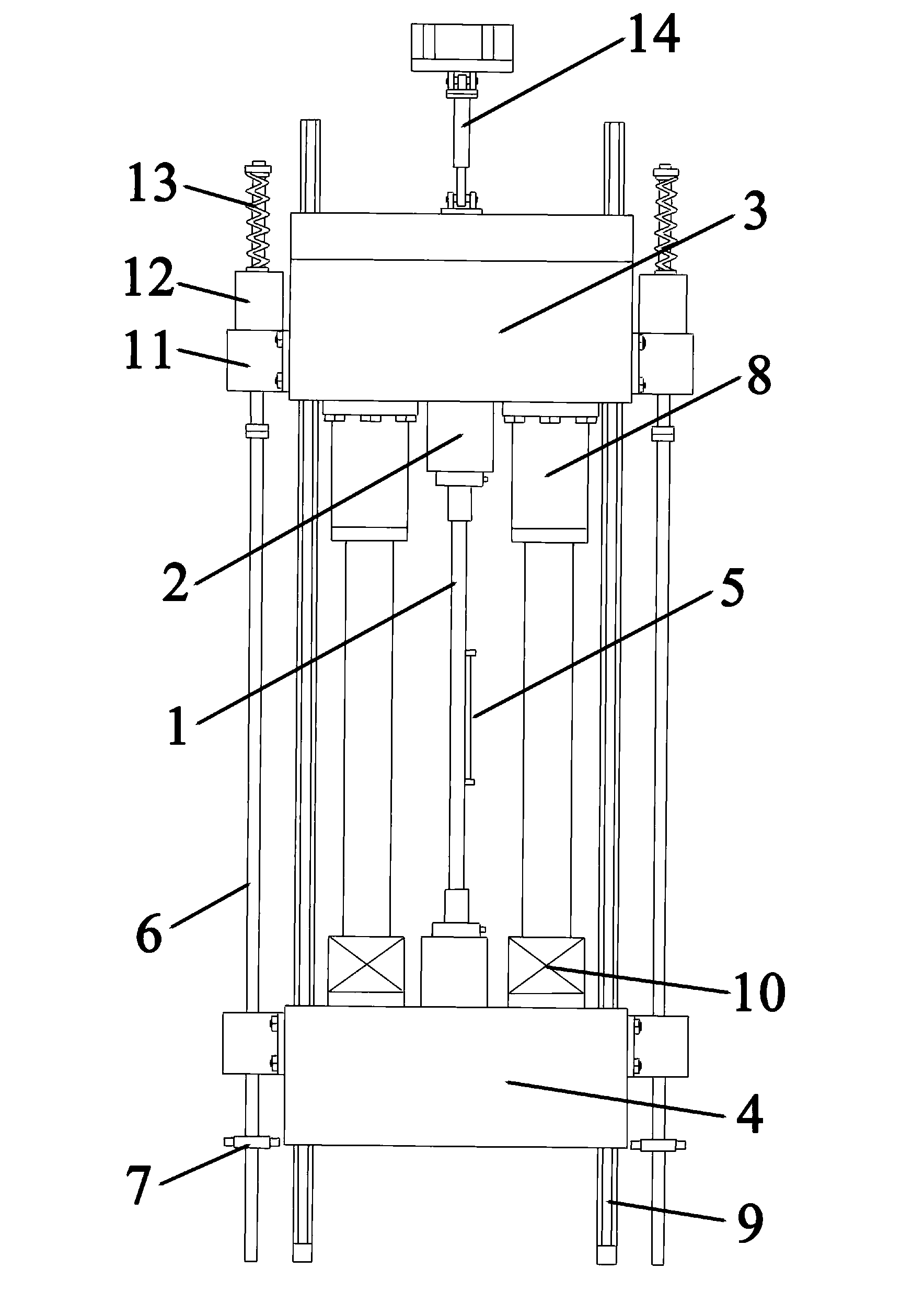

[0023] refer to figure 1 , figure 2 As shown, a buffer device for a tensile testing machine for super-large load structures includes a clamp 2, a main chuck 3, an auxiliary chuck 4, a displacement sensor 5 (such as an extensometer, a strain gauge, etc.), a buffer rod 6, and a buffer stop Ring 7, loading cylinder 8, guide rail 9, force sensor 10 (resistance strain gauge sensor, piezoelectric sensor, capacitive sensor, inductive sensor, etc.), hydraulic buffer cylinder 11, hydraulic buffer cylinder 12, spring 13, reset cylinder 14 ( Pneumatic reset cylinder, hydraulic reset cylinder, etc.), buffer cylinder piston 15 and buffer cylinder barrel 16.

[0024] Among them, the auxiliary chuck 4 is fixedly connected on the testing machine, one end of the guide rail 9 is fixed on the auxiliary chuck 4, the other end of the guide rail 9 is connected with the main chuck 3, and the main chuck 3 is located on the testing machine, and can only move along the guide rail. 9 to move; the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com