Laser straightness and displacement measuring device

A measuring device and straightness technology, which can be used in measuring devices, using optical devices, instruments, etc., can solve the problems of high requirements for device pairing, high difficulty, and decreased signal amplitude and contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below in conjunction with the accompanying drawings.

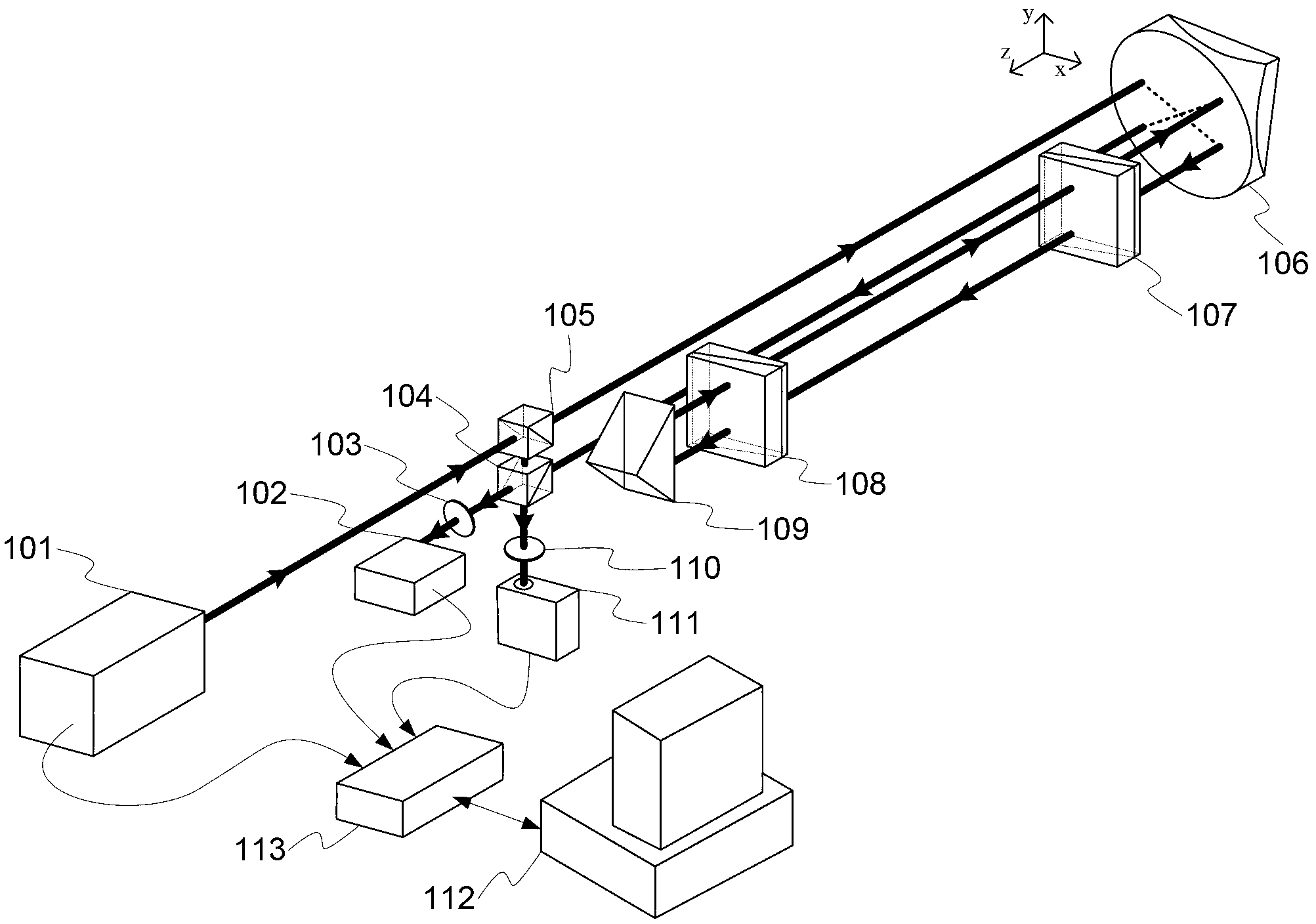

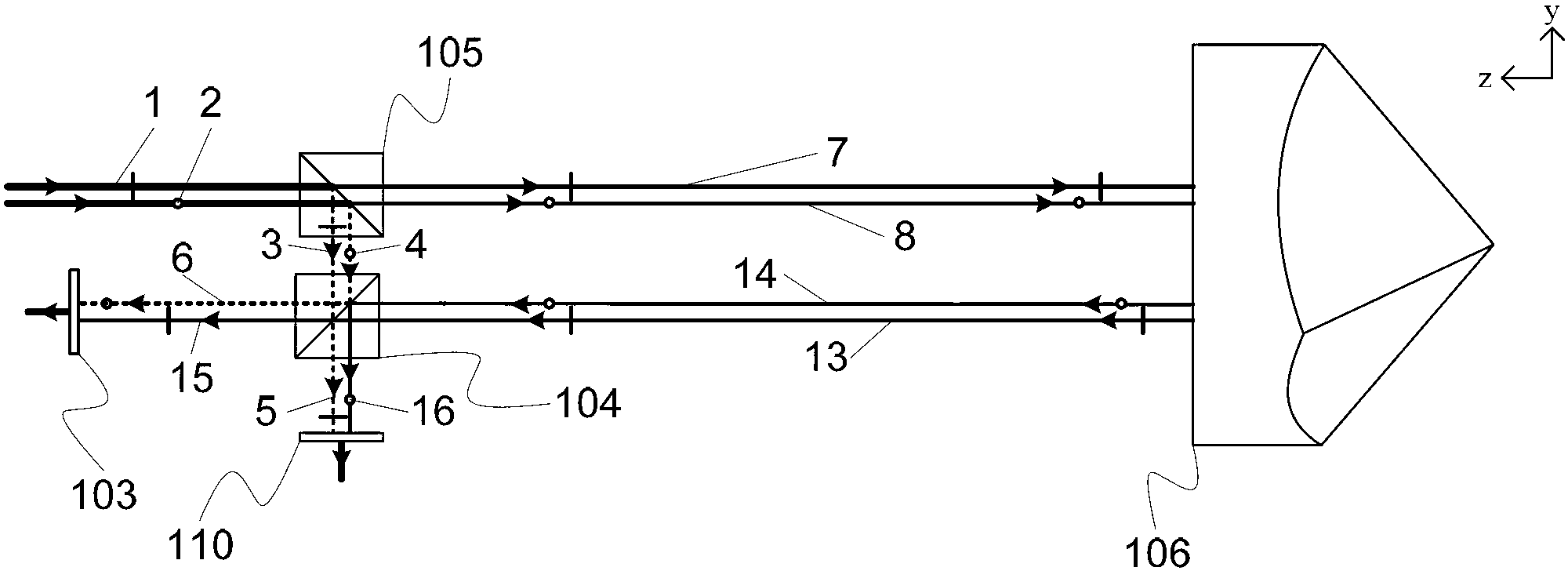

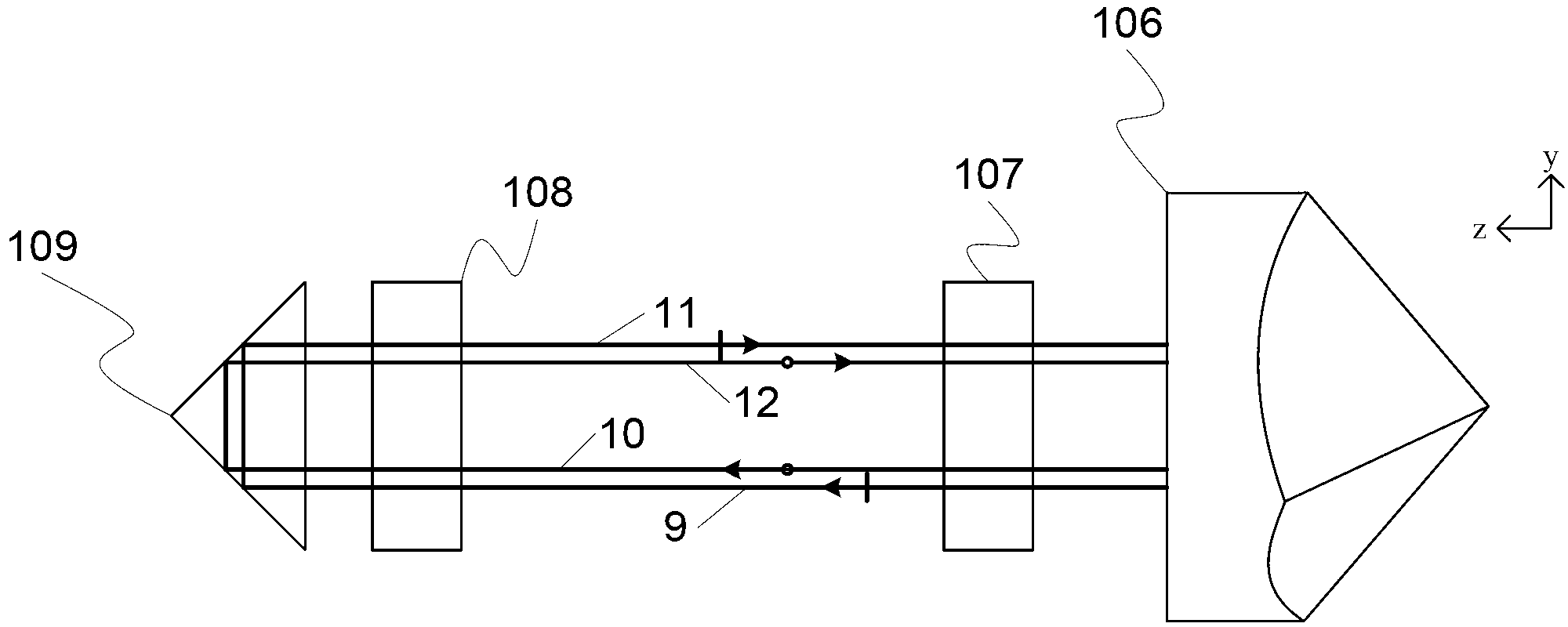

[0029] figure 1 It is a schematic diagram of the preferred structure of the measuring device for laser straightness and displacement of the present invention, including a dual-frequency laser light source 101, an ordinary beam splitter 105 sequentially arranged on the optical path axis at the emitting end of the dual-frequency laser light source 101, and a first optical path turning mirror 106 , the first Wollaston prism 107, the second Wollaston prism 108, the reference reflector 109 and the polarization beam splitter 104, the first analyzer 103 that is respectively arranged on the reflected light path of the polarization beam splitter 104 and the transmission light path and the first photoelectric receiver 102, the second polarizer 110 and the second photoelectric receiver 111, the phaser 113 connected with the dual-frequency laser light source 101, the first photoelectric r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com