Thermal power generating system adopting fixed dot array solar focusing

A thermal power generation system and solar energy technology, applied in the field of solar energy utilization, can solve the problems of low solar energy collection efficiency, unutilization, and large scale, and achieve the effects of overcoming low solar energy collection time, improving utilization time and efficiency, and improving tracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

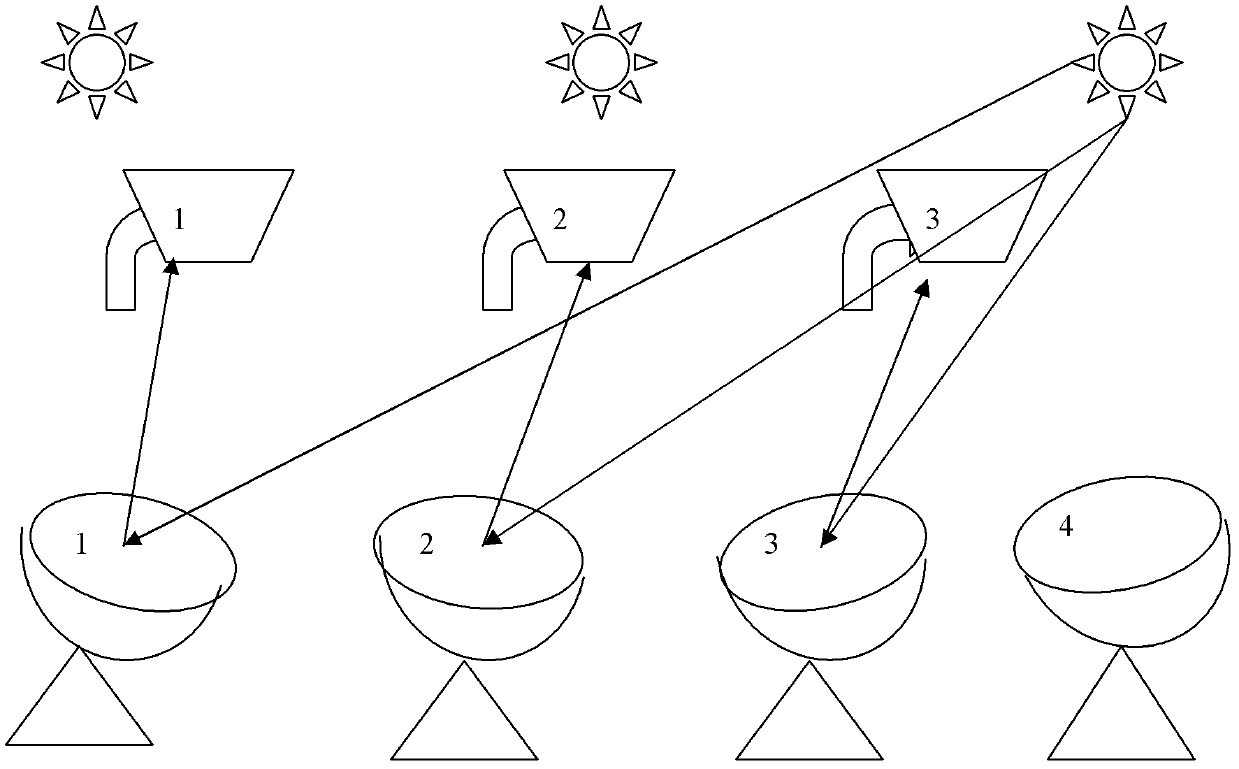

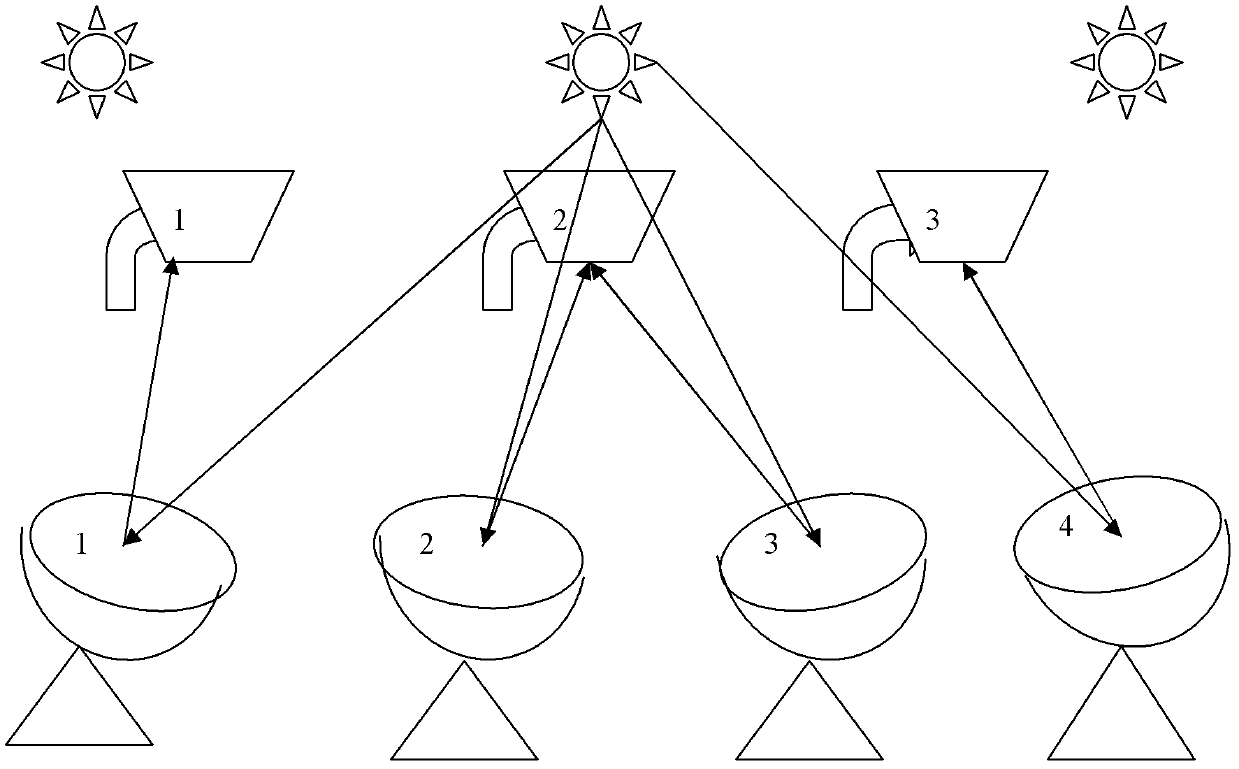

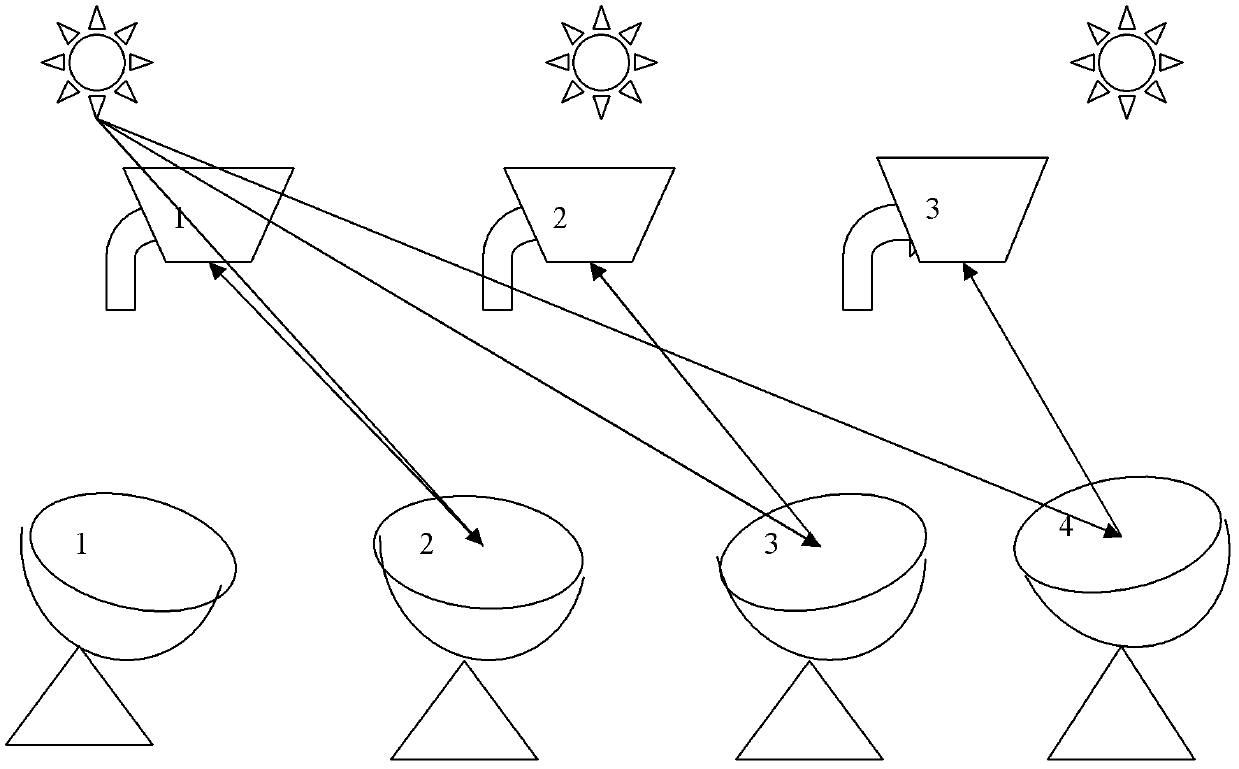

[0062] Example 1: Fixed point array solar focused thermal power generation system composed of 4 solar mirrors and 3 solar photothermal conversion devices

[0063] as attached figure 1 , 2 , The fixed-point array solar concentrating thermal power generation system composed of 4 solar mirrors and 3 solar photothermal conversion devices shown in 3, figure 1 , 2 , 3 are the collection and utilization of solar energy in the morning, noon and afternoon respectively, figure 1 In the morning, the sun rises from the east, solar mirrors 1, 2, and 3 focus the solar energy on the solar light-to-heat conversion devices 1, 2, and 3 respectively, realizing the tracking and focusing of solar energy; figure 2 At noon, the sun is located in the central area of the sky, No. 1 and No. 4 solar mirrors focus solar energy on No. 1 and No. 3 solar photothermal conversion devices respectively, and No. 2 and No. 3 solar mirrors focus on No. 2 solar storage equipment to realize tracking and focusi...

Embodiment 2

[0065] Example 2: A fixed-point array solar concentrating thermal power generation system composed of 12 solar mirrors and 6 solar photothermal conversion devices

[0066] This example Figure 4 The fixed-point array solar concentrating thermal power generation system shown consists of 12 solar mirrors and 6 solar photothermal conversion devices. The 12 solar mirrors are arranged in an array of three rows and four columns, and the 6 solar photothermal conversion devices are arranged in three rows. The arrays of 2 columns are arranged, and the solar photothermal conversion devices are respectively arranged in the middle areas of the three rows of solar mirrors.

[0067] In the different time periods of morning, noon, and afternoon, solar mirrors 1-12 can choose different solar photothermal conversion devices from 1-6 to focus, and select different focus points to focus according to the actual solar energy collection efficiency. For solar mirrors 1-12 at different positions, th...

Embodiment 3

[0070] Embodiment 3: 1*3 parabolic fixed-point array solar tracking and focusing thermal power generation system

[0071] as attached Figure 5As shown, this embodiment adopts three parabolic dish solar mirrors (2), which are arranged on a parabolic connecting part, and each solar mirror is provided with two rotating shafts, that is, the horizontal axis and the vertical axis. The horizontal axis and the vertical axis intersect perpendicularly to form a system axis, and each solar mirror is connected to a parabolic connecting part through a system axis. This embodiment consists of three system axes arranged on the connecting parts and a support connected to the ground The solar mirror bracket, the connecting parts do not move, but the three system axes move, the solar tracking control device is set to connect with each system axis, and physical and optical sensors are set on each solar mirror (2), the solar tracking control device is The integrated electronic control device co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com