Internal combustion burner for domestic gas stove

A technology of gas stoves and burners, which is applied in the direction of gas fuel burners, burners, and combustion methods, and can solve the problems of internal combustion fire burners such as poor high temperature resistance and corrosion resistance, increased smoke exhaust resistance, and easy rusting of sealing surfaces etc. to achieve the effects of reducing heat loss, improving thermal efficiency, and stabilizing combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

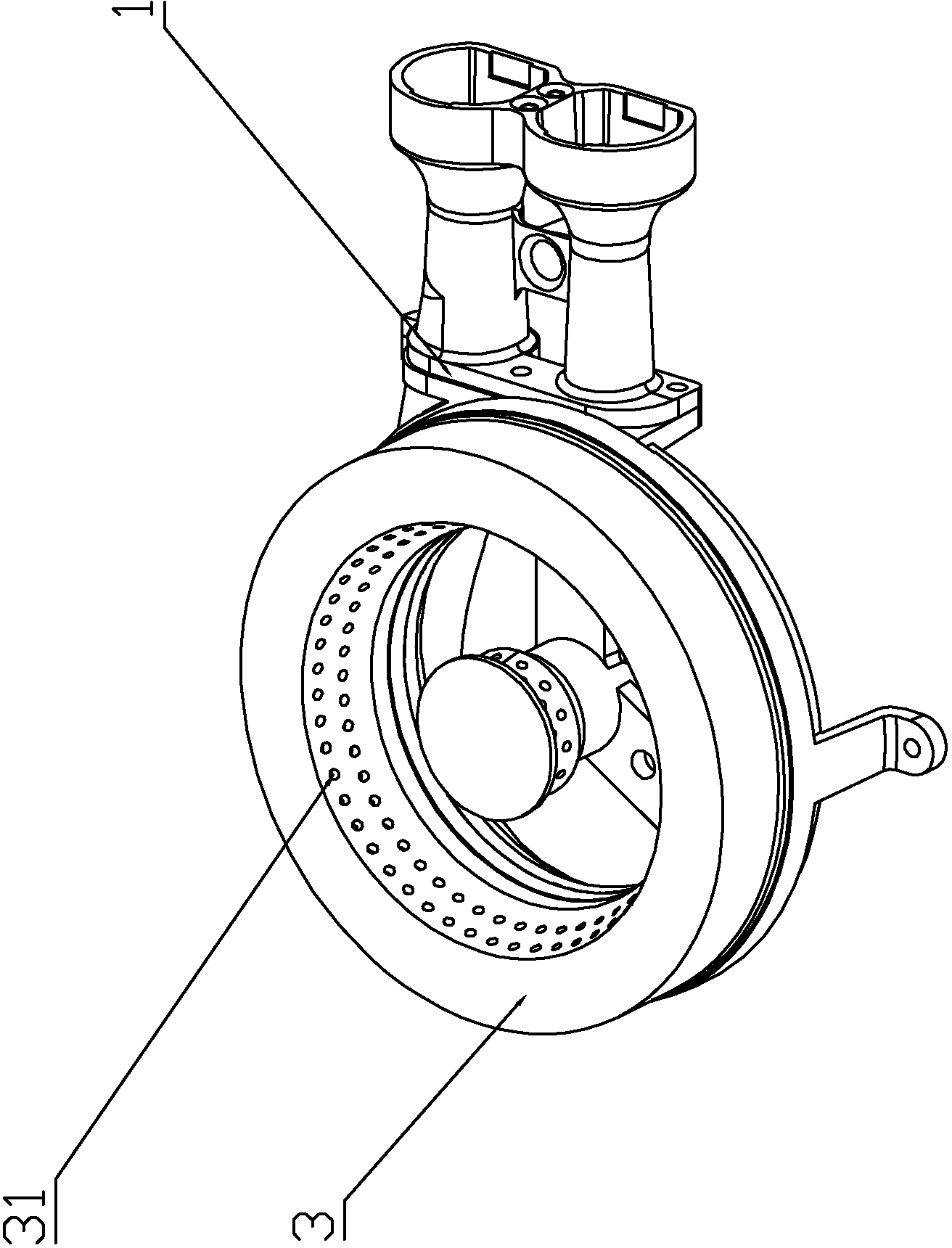

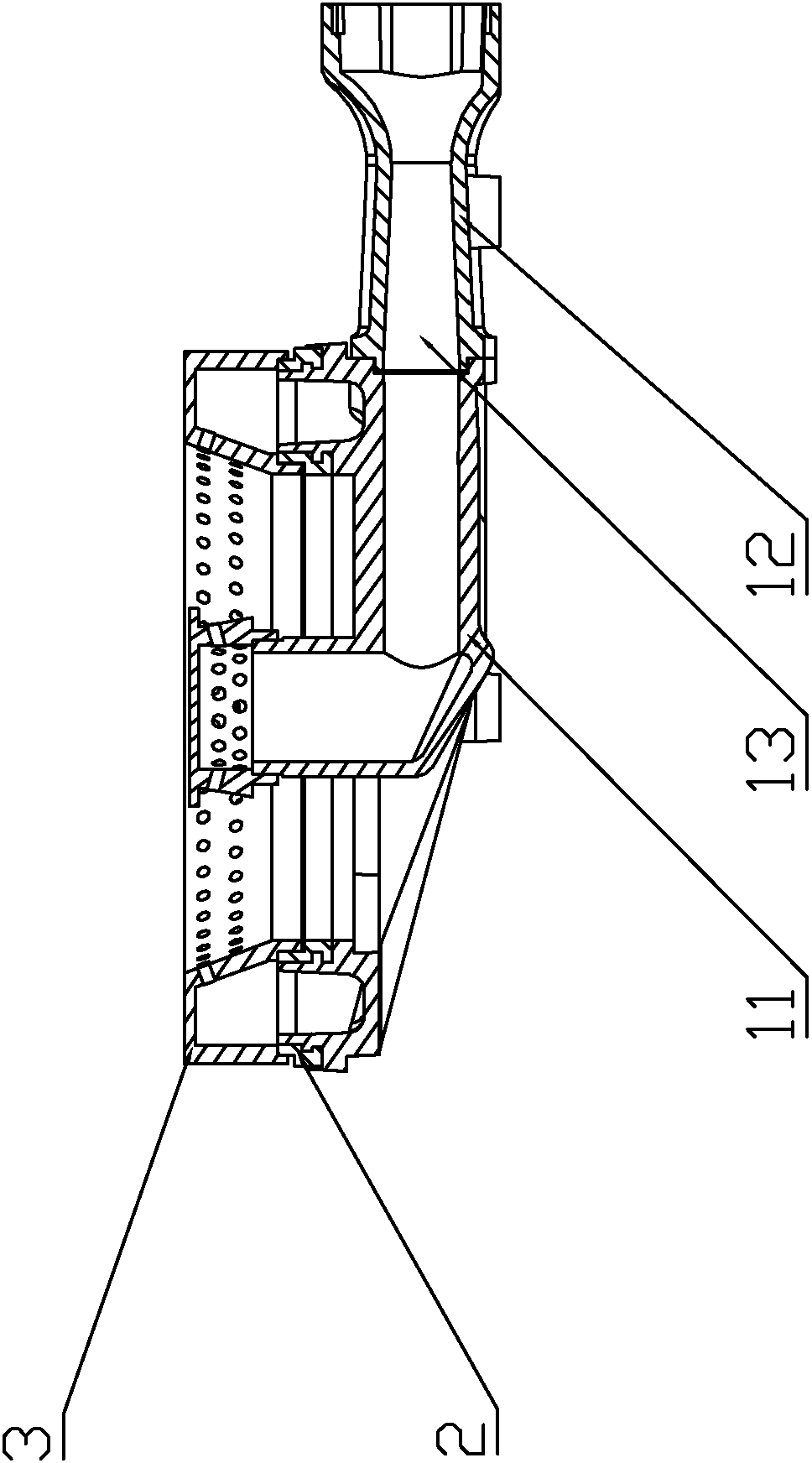

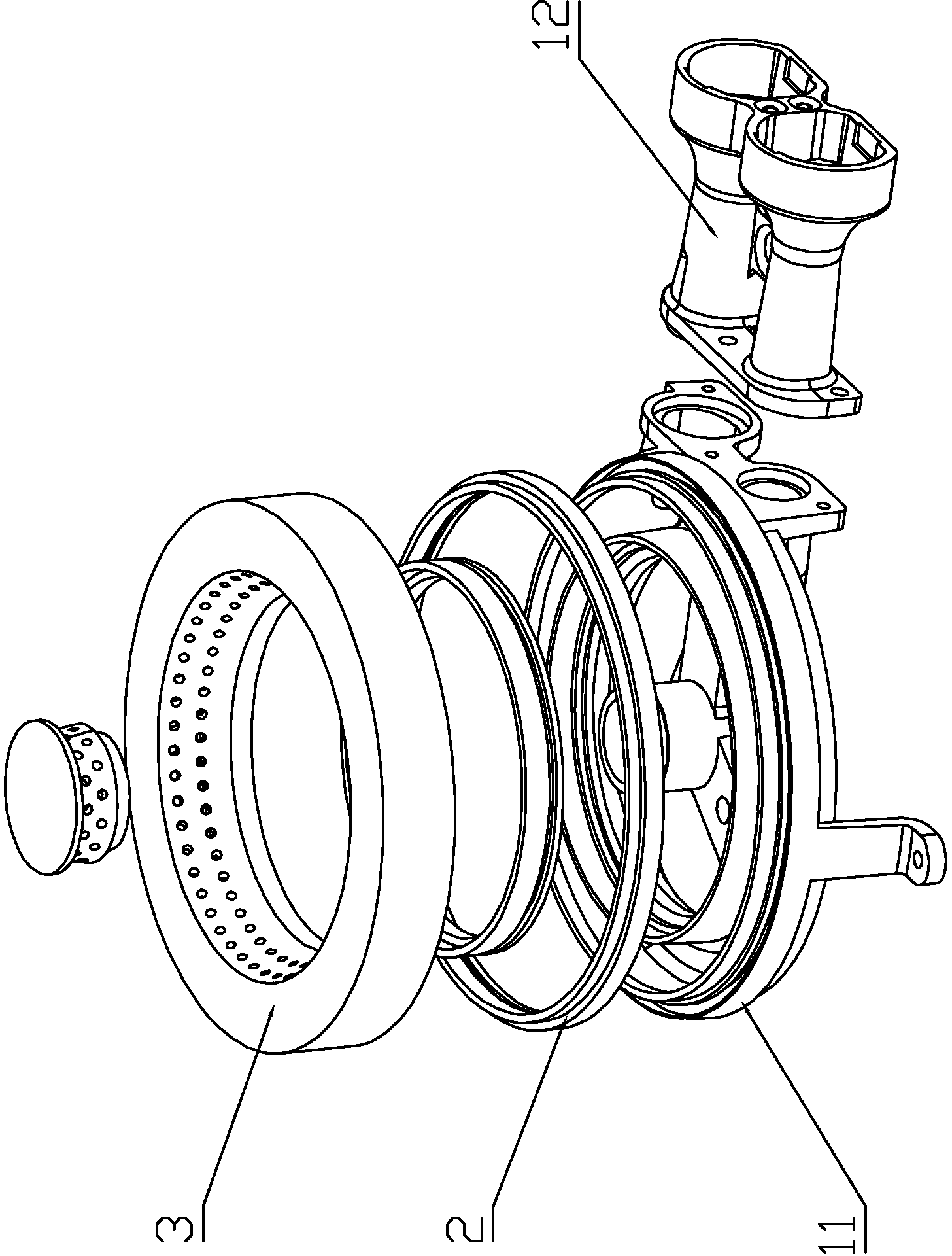

[0021] Specific implementation method: see attached figure 1 , attached figure 2 , attached image 3 As shown, this embodiment includes a burner main body 1, an outer ring fire distribution device 3, and the outer ring fire distribution device 3 is provided with a fire outlet 31, and it also includes a connecting seat 2, which is made of a high temperature resistant material with a resistance of more than 700 degrees into, such as copper alloy materials, stainless iron alloy materials, high temperature resistant ceramic materials, asbestos materials and carbon fiber composite materials, etc. The connection seat 2 is installed on the burner body 1, the outer ring fire distributor 3 is installed on the connection seat 2, the fire outlet 31 is a fire outlet hole, and the fire outlet hole is that the central axis of the fire outlet is staggered from the central axis of the outer ring fire distributor 3 hole.

[0022] The outer ring fire distribution device 3 can be provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com