A kind of preparation method of polyimide-carbon nanotube composite fiber

A carbon nanotube composite, carbon nanotube technology, applied in the field of polymers, can solve problems such as mechanical properties, thermal properties and electrical properties need to be improved, product performance description, etc., to improve thermal stability, modulus, and uniform heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

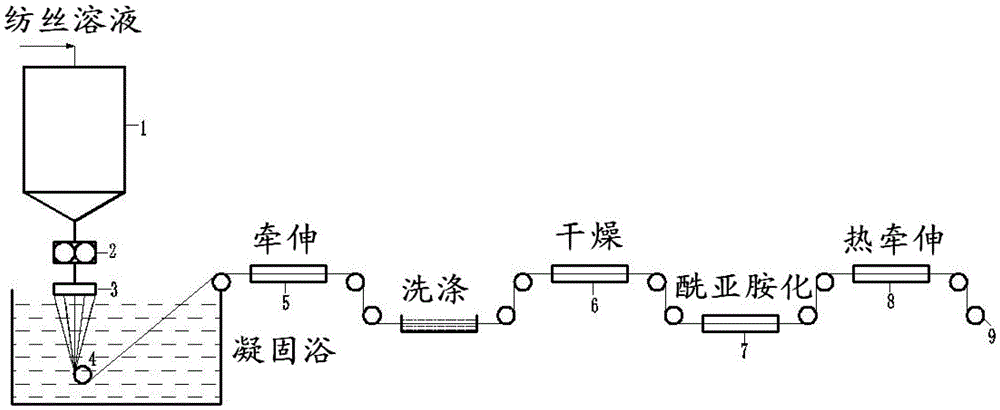

[0031] The invention provides a kind of preparation method of polyimide-carbon nanotube composite fiber, comprises the following steps:

[0032] a) providing surface-modified carbon nanotubes;

[0033] b) reacting the surface-modified carbon nanotubes with diamine monomers and dianhydride monomers in an organic solvent to obtain a polyamic acid-carbon nanotube composite;

[0034] c) spinning the polyamic acid-carbon nanotube composite obtained in step b) to obtain a polyamic acid-carbon nanotube composite fiber;

[0035] d) Imidizing and thermally drawing the polyamic acid-carbon nanotube composite fibers obtained in step c) to obtain polyimide-carbon nanotube composite fibers.

[0036] The method provided by the invention carries out surface modification to carbon nanotubes, so that the polymerization reaction of diamine and dianhydride is carried out in situ on the surface-modified carbon nanotubes, so that there is a good interface between the obtained polyamic acid and ca...

Embodiment 1

[0061] Add 5.00 g of carbon nanotubes, 150 mL of concentrated H to the flask 2 SO 4 and 50mL concentrated HNO 3 , first ultrasonic at 30°C for 2 hours, then stirred at 70°C for 24 hours; cool to room temperature, add deionized water to dilute, let stand until the carbon nanotubes precipitate, pour off the brownish-yellow clear liquid in the upper layer, and the black suspension in the lower layer Filtrate and wash until the filtrate becomes neutral to obtain a black filter cake of carbon nanotubes; vacuum-dry the obtained black filter cake at 100° C. for 24 hours to obtain carboxylated carbon nanotubes, which are stored for later use;

[0062] At room temperature, 0.375 g of the obtained carboxylated carbon nanotubes was added to 60 mL N, N-dimethylacetamide (DMAC) for ultrasonic dispersion for 2 h to obtain a uniform black suspension of carbon nanotubes in DMAC; under nitrogen protection, Add 170.204g (0.850mol) of diaminodiphenyl ether (ODA), 50.017g (0.170mol) of biphenyl...

Embodiment 2

[0071] At room temperature, 1.50 g of the carboxylated carbon nanotubes prepared in Example 1 were added to 100 mL of DMAC for ultrasonic dispersion for 2 hours to obtain a black uniform suspension of carbon nanotubes in DMAC; under nitrogen protection, sequentially add 136.163g (0.680mol) ODA and 273.360g (0.680mol) 4,4'-p-phenylene diether dianhydride, then add 1500mL DMAC to it, and react the resulting mixed solution at room temperature for 2 days, then carry out the reaction solution Filtration and defoaming to obtain spinning stock solution;

[0072] use figure 1 The schematic diagram of the dry and wet spinning process shown in the figure spins the obtained spinning dope, and the specific parameters are as follows:

[0073] The spinneret has 100 holes, the hole diameter is Φ0.16mm, the spray ratio is 2.0 times, and the air layer height is 120mm; after the as-spun fibers are washed with water, they are dried with hot rollers to obtain polyamic acid-carbon nanotube compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com