Method for producing baohuoside I through herba epimdii

A technology of epimedium and baohuoside, which is applied in the field of extraction of traditional Chinese medicine components, can solve the problems of cumbersome and difficult control, high concentration energy consumption, product damage, etc., and achieve the effects of simple process operation, easy separation and purification, and reduced product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

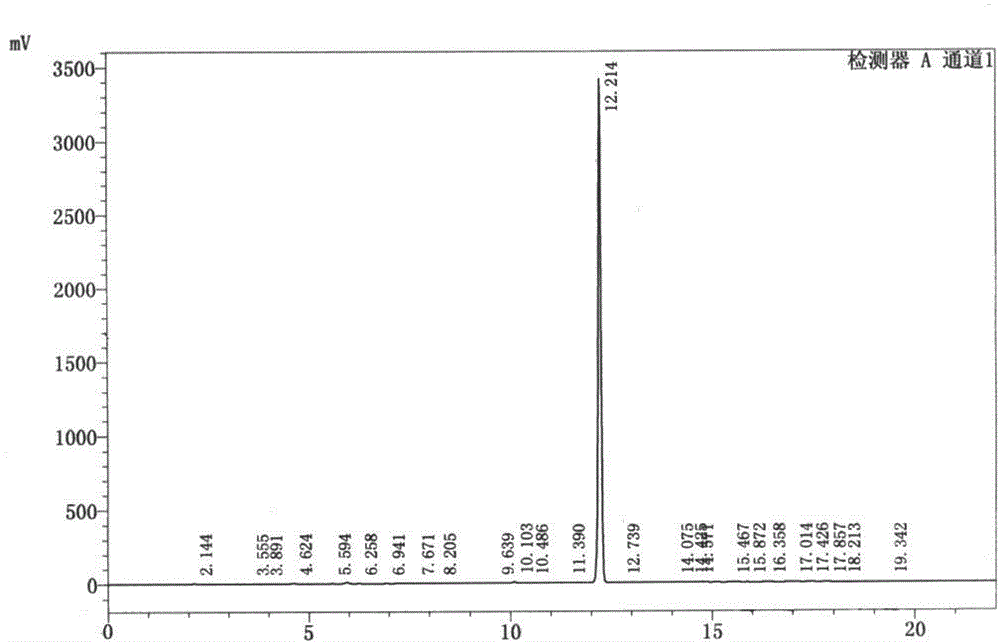

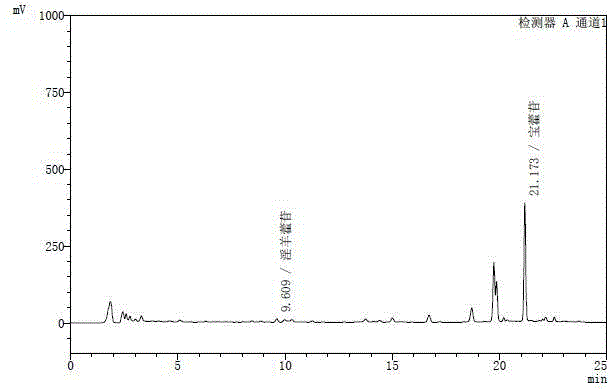

Image

Examples

Embodiment 1

[0059] The method that epimedium ferment produces baohuoside I, it comprises the following steps:

[0060] S1. Take 40g of high-activity dry yeast and multiply in the culture medium for 10 hours. The expansion culture conditions are pH 6-7, temperature 25°C, static fermentation, and then add 2 times the amount of water to the volume of the expansion solution to obtain a culture solution; The medium is prepared by adding water to starch, the amount of starch is 500 times the weight of yeast (20kg), the weight ratio of water to starch added to the starch is 6:1, and the starch is wheat flour; highly active dry yeast It is "highly active dry yeast" stipulated in the industry standard QR / T1501-92 of the People's Republic of China, excellent grade or first grade product; fermentation power ≥ 750ml (CO 2 ).

[0061] S2. Mix the nutrient solution obtained in step S1 with 240 kg of dried epimedium pulverized to 10 to 20 meshes, detect that the content of icariin is 0.55%, stir evenl...

Embodiment 2

[0072] The method that epimedium ferment produces baohuoside I, it comprises the following steps:

[0073] S1. Take 300g of highly active dry yeast and multiply it in the culture medium for 8 hours. The expansion culture conditions are pH 6-7, temperature 35°C, static fermentation, and then add 2.5 times the amount of water according to the volume of the expansion solution to dilute to obtain a culture solution; The medium is prepared by adding water to starch, the amount of starch is 666.7 times the weight of the yeast (200kg), the weight ratio of water to starch added to the starch is 5:1, and the starch is wheat flour; highly active dry yeast It is "highly active dry yeast" stipulated in the industry standard QR / T1501-92 of the People's Republic of China, excellent grade or first grade product; fermentation power ≥ 750ml (CO 2 ).

[0074] S2. Mix the culture solution obtained in step S1 with 2.4 tons of dried epimedium dried raw materials crushed to 10-20 meshes, stir eve...

Embodiment 3

[0084] The method that epimedium ferment produces baohuoside I, it comprises the following steps:

[0085] S1. Take 40g of high-activity dry yeast and multiply in the culture medium for 12 hours. The expansion culture conditions are pH 6-7, temperature 15°C, static fermentation, and then add 2 times the amount of water according to the volume of the expansion solution to dilute to obtain a culture solution; The medium is prepared by adding water to starch, the amount of starch is 800 times the weight of the yeast, the weight ratio of water and starch added to the starch is 4:1, the starch is wheat flour; highly active dry yeast is Chinese people's "Highly active dry yeast" stipulated in the industry standard of the Republic QR / T1501-92, superior or first-class product; fermentation power ≥ 750ml (CO 2 ).

[0086] S2, mix the nutrient solution obtained in step S1 with 1000 kg of the fresh epimedium that is crushed to 10-20 meshes, stir evenly, the weight ratio of the fresh ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com