Plastic for automobile steering wheel and preparation method thereof

A steering wheel and automobile technology, which is applied in the field of plastics and its preparation, can solve the problems of breeding bacteria and easy aging of the steering wheel, and achieves the effect of light weight and ensuring driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

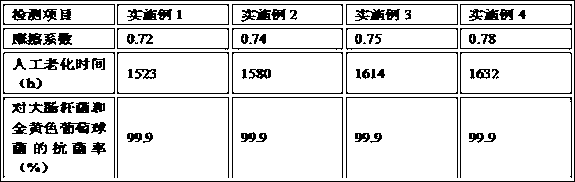

Embodiment 1

[0035] The present embodiment provides a kind of plastics for automobile steering wheel, which contains the following components in parts by mass:

[0036] Polypropylene 75 parts

[0037] 15 parts glass fiber

[0038] EPDM rubber 10 parts

[0039] 5 parts styrene-butadiene rubber

[0040] 1.2 parts of dibutyl hydroxytoluene

[0041] Dilauryl thiodipropionate 0.8 parts

[0042] Antioxidant 168 0.5 parts

[0043] Chlorinated paraffin 0.4 parts

[0044] Polyethylene wax 0.15 parts

[0045] Nano copper oxide 0.3 parts

[0046] 8 parts of white oil.

[0047] The preparation steps of plastics for automobile steering wheel are as follows:

[0048] The first step: Add polypropylene, glass fiber, EPDM rubber, styrene-butadiene rubber, antioxidant 168, chlorinated paraffin and polyethylene wax into the mixer, at a speed of 350-400rpm and a temperature of 100-120 Stir at ℃ for 5-10 minutes;

[0049] The second step: then add dibutyl hydroxytoluene, dilauryl thiodipropionate, n...

Embodiment 2

[0052] The present embodiment provides a kind of plastics for automobile steering wheel, which contains the following components in parts by mass:

[0053] Polypropylene 80 parts

[0054] 18 parts glass fiber

[0055] EPDM rubber 17 parts

[0056] 6 parts styrene-butadiene rubber

[0057] 2 parts butyl hydroxytoluene

[0058] Dilauryl thiodipropionate 0.8 parts

[0059] Antioxidant 168 1 part

[0060] Chlorinated paraffin 0.5 parts

[0061] Polyethylene wax 0.2 parts

[0062] Nano copper oxide 0.5 parts

[0063] 10 parts white oil.

[0064] The preparation steps of plastics for automobile steering wheel are as follows:

[0065] The first step: Add polypropylene, glass fiber, EPDM rubber, styrene-butadiene rubber, antioxidant 168, chlorinated paraffin and polyethylene wax into the mixer, at a speed of 350-400rpm and a temperature of 100-120 Stir at ℃ for 5-10 minutes;

[0066] The second step: then add dibutyl hydroxytoluene, dilauryl thiodipropionate, nano-copper oxid...

Embodiment 3

[0069] The present embodiment provides a kind of plastics for automobile steering wheel, which contains the following components in parts by mass:

[0070] Polypropylene 88 parts

[0071] 23 parts glass fiber

[0072] EPDM rubber 25 parts

[0073] 10 parts of styrene-butadiene rubber

[0074] 3.5 parts of dibutyl hydroxytoluene

[0075] Dilauryl thiodipropionate 1.2 parts

[0076] Antioxidant 168 1.5 parts

[0077] Chlorinated paraffin 0.7 parts

[0078] Polyethylene wax 0.33 parts

[0079] Nano copper oxide 0.7 parts

[0080] 14 parts of white oil.

[0081] The preparation steps of plastics for automobile steering wheel are as follows:

[0082] The first step: Add polypropylene, glass fiber, EPDM rubber, styrene-butadiene rubber, antioxidant 168, chlorinated paraffin and polyethylene wax into the mixer, at a speed of 350-400rpm and a temperature of 100-120 Stir at ℃ for 5-10 minutes;

[0083] The second step: then add dibutyl hydroxytoluene, dilauryl thiodipropiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com