Preparation process of double aqueous phase decoloring flocculant emulsion

A decolorizing flocculant and a preparation process technology are applied in the field of preparation technology of a two-phase decolorizing flocculant emulsion, which can solve the problems of poor comprehensive performance of decolorization and flocculation, and achieve the effect of simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of dicyandiamide formaldehyde condensation polymer:

[0030] Add 21.02g (0.25mol) of dicyandiamide and 35.9ml of 37-40wt% (0.50mol) formaldehyde solution into a three-neck round bottom flask equipped with a reflux condensing device, adjust the temperature of the water bath to 80°C, and react at constant temperature for 1 hour. Then, add 6.42g (0.12mol) of modifier ammonium chloride and 4.00g (0.03mol) of catalyst aluminum trichloride in sequence, adjust and keep the water bath temperature at 70°C, and react for 1.4h to obtain dicyandiamide formaldehyde condensation polymer aqueous solution .

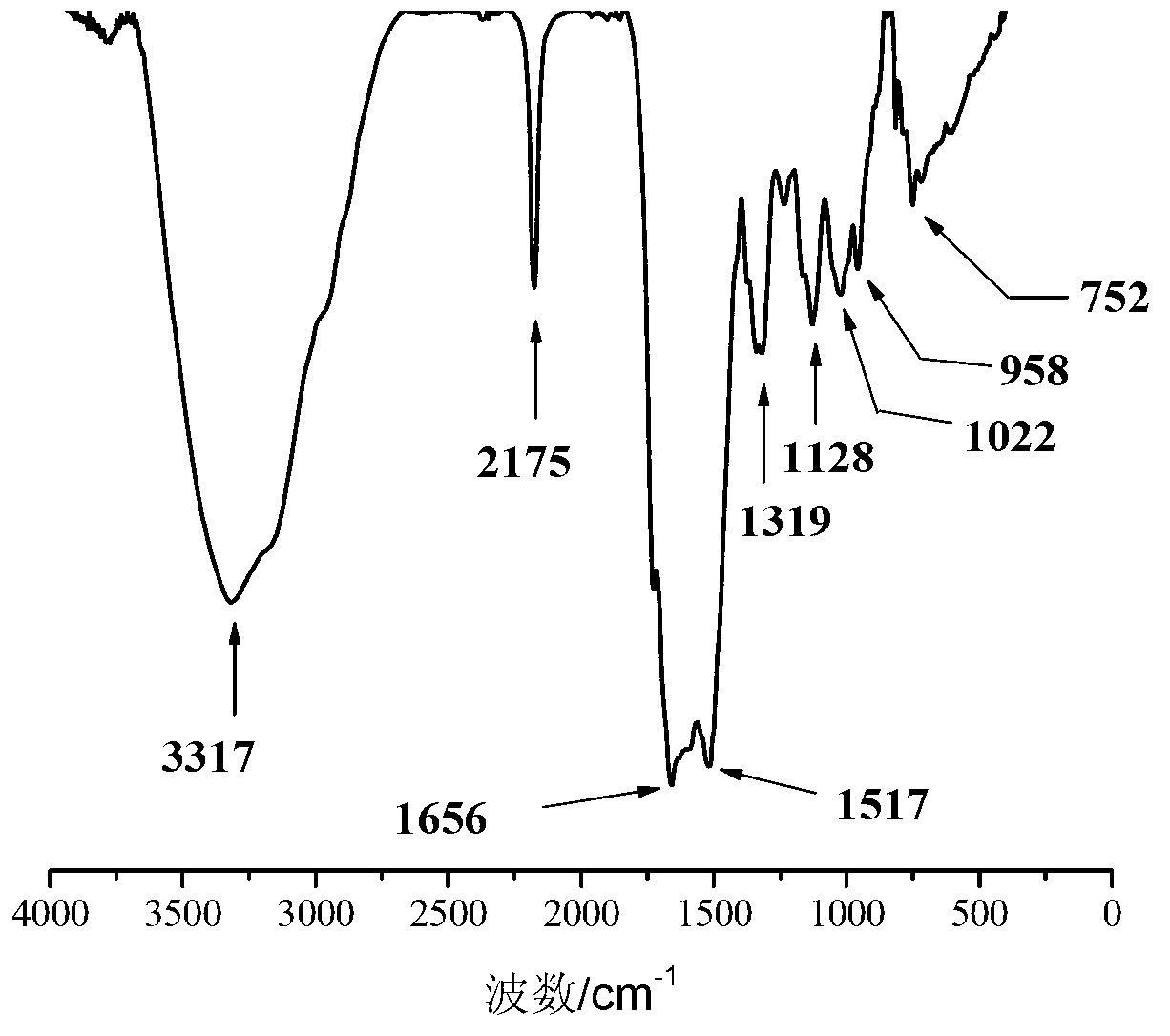

[0031] Depend on figure 1 The infrared spectrum analysis is as follows: interval 4000~2500cm -1 It is the stretching vibration region of X-H (X includes C, N, O, S, etc.). Since the reactant is an amine compound, it should be the N-H stretching vibration line, so it can be judged that the product contains primary or secondary amine groups; 2500~2000cm -1 It is ...

Embodiment 2

[0039] (1) Preparation of dicyandiamide formaldehyde condensation polymer:

[0040] Add 21.02g (0.25mol) of dicyandiamide and 28.0ml of formaldehyde solution with a mass concentration of 37 to 40wt% (0.39mol) into a three-neck round bottom flask equipped with a reflux condensing device, adjust the temperature of the water bath to 80°C, and react at a constant temperature 1h. Then, add 4.28g (0.08mol) of modifier ammonium chloride and 5.33g (0.04mol) of catalyst aluminum trichloride in sequence, adjust and keep the water bath temperature at 65°C, and react for 1.2h to obtain dicyandiamide formaldehyde condensation polymer solution .

[0041] (2) Preparation of two-phase decolorizing flocculant emulsion

[0042] Taking the mass of the reaction system solution as the total mass, and using 60.00 g of the dicyandiamide formaldehyde condensation polymer aqueous solution prepared above as the dispersion medium, the dicyandiamide formaldehyde condensation polymer mass accounts for 4...

Embodiment 3

[0047] (1) Preparation of dicyandiamide formaldehyde polycondensate

[0048] Add 31.11g (0.37mol) of dicyandiamide and 53.8ml of formaldehyde solution with a mass concentration of 37-40wt% (0.75mol) into a three-necked round-bottomed flask equipped with a reflux condensing device, adjust the temperature of the water bath to 75°C, and react at a constant temperature 1h. Then, add modifier ammonium chloride 11.77g (0.22mol) and catalyst aluminum trichloride 4.00g (0.03mol) in sequence, adjust and keep the water bath temperature at 60°C, and react for 1.4h to obtain dicyandiamide formaldehyde condensation polymer solution .

[0049] (2) Preparation of two-phase decolorizing flocculant emulsion

[0050] Taking the mass of the reaction system solution as the total mass, and taking 105.00 g of the self-made dicyandiamide formaldehyde condensation polymer aqueous solution as the dispersion medium, the dicyandiamide formaldehyde condensation polymer mass accounts for 45.9wt% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com