Preparation method of 2,6-dihydroxytoluene

A technology of dihydroxytoluene and diaminotoluene, applied in 2 fields, can solve the problems of short service life and large investment, and achieve the effect of avoiding the interference of acid liquid, high quality, avoiding the use of high-pressure equipment and corrosion-resistant materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

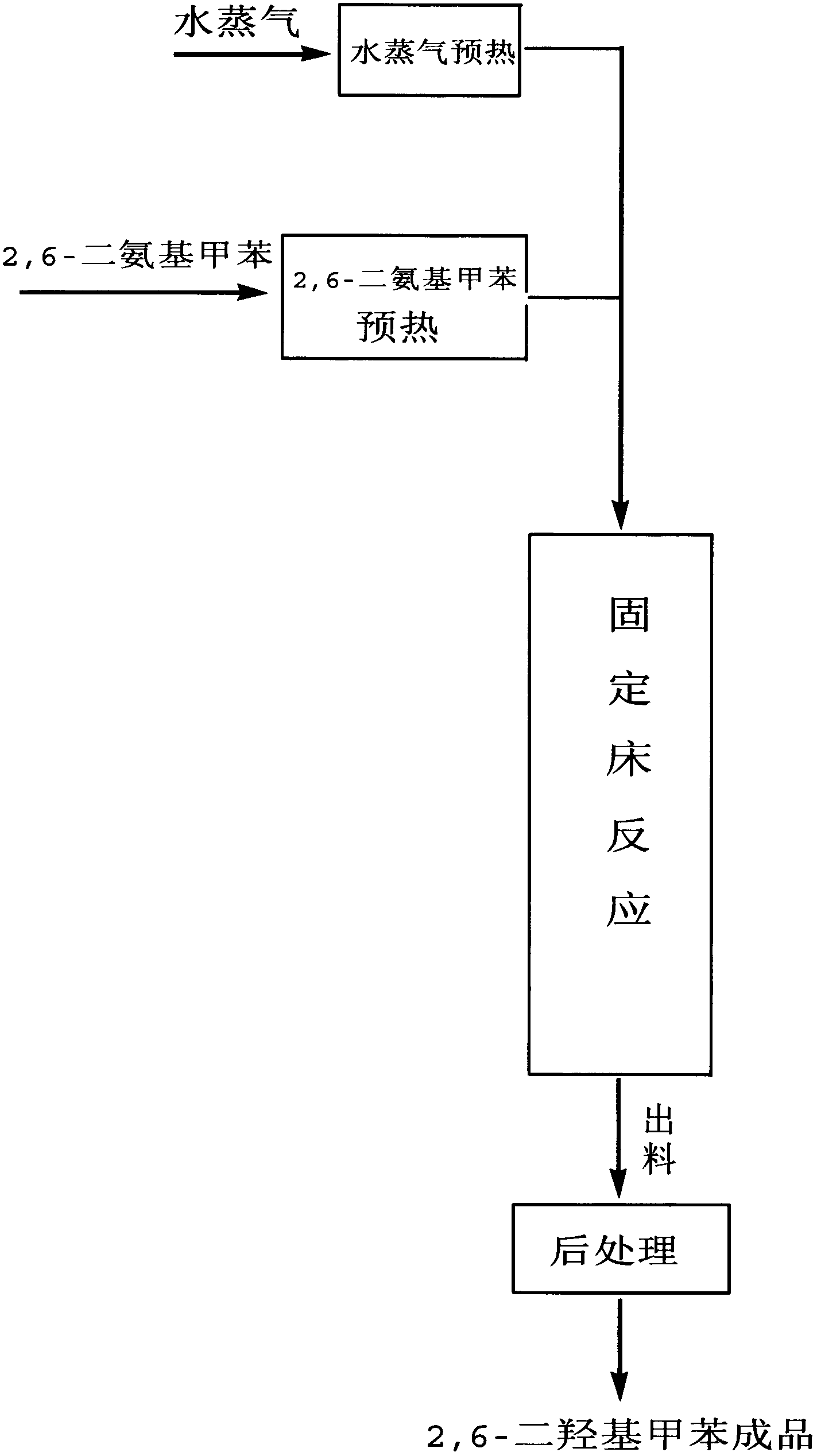

[0063] Such as figure 1 As shown, a 10cm high ceramic ring filler is filled at the bottom of the fixed bed tubular stainless steel reactor (inner diameter 3cm, length 1m), and then a 10g solid acid catalyst is filled (the solid acid catalyst is made of SO 4 2- / ZrO 2 A composite solid acid catalyst composed of solid acid and HZSM-5 molecular sieve, the HZSM-5 silicon-aluminum ratio is 20), and the upper part of the composite solid acid catalyst is filled with a 20cm high ceramic ring filler.

[0064] Turn on the power, set the internal temperature of the fixed bed reactor at 360°C, set the internal temperature of the steam heater (stainless steel tube, inner diameter 3cm, length 50cm) at 320°C, and start the peristaltic pump (BT1-100E, flow 0.07~98ml / min), input the deionized water into the steam heater, control the flow rate of deionized water to be 10ml / min, the water vapor is pumped in from the upper inlet of the fixed bed reactor, and exported from the lower end of the f...

Embodiment 2

[0069] On the basis of Example 1, only the loading amount of the composite solid acid catalyst was changed to 1 gram, the silicon-aluminum ratio of HZSM-5 was 25, and the temperature was raised to 150°C when 2,6-diaminotoluene was heated and melted. Other technological processes and parameters The results are shown in Table 1.

Embodiment 3

[0071] On the basis of Example 1, only change the loading amount of the composite solid acid catalyst to 2 grams, the HZSM-5 silicon-aluminum ratio is 30, 2,6-diaminotoluene is heated to 200 ° C when it is heated and melted, other process flow and parameters The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com