System for treating wastewater containing heavy oil

A waste water and heavy oil technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve large economic burden, violate clean production, increase energy consumption and cost of sewage treatment, etc. problem, to achieve the effect of low cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

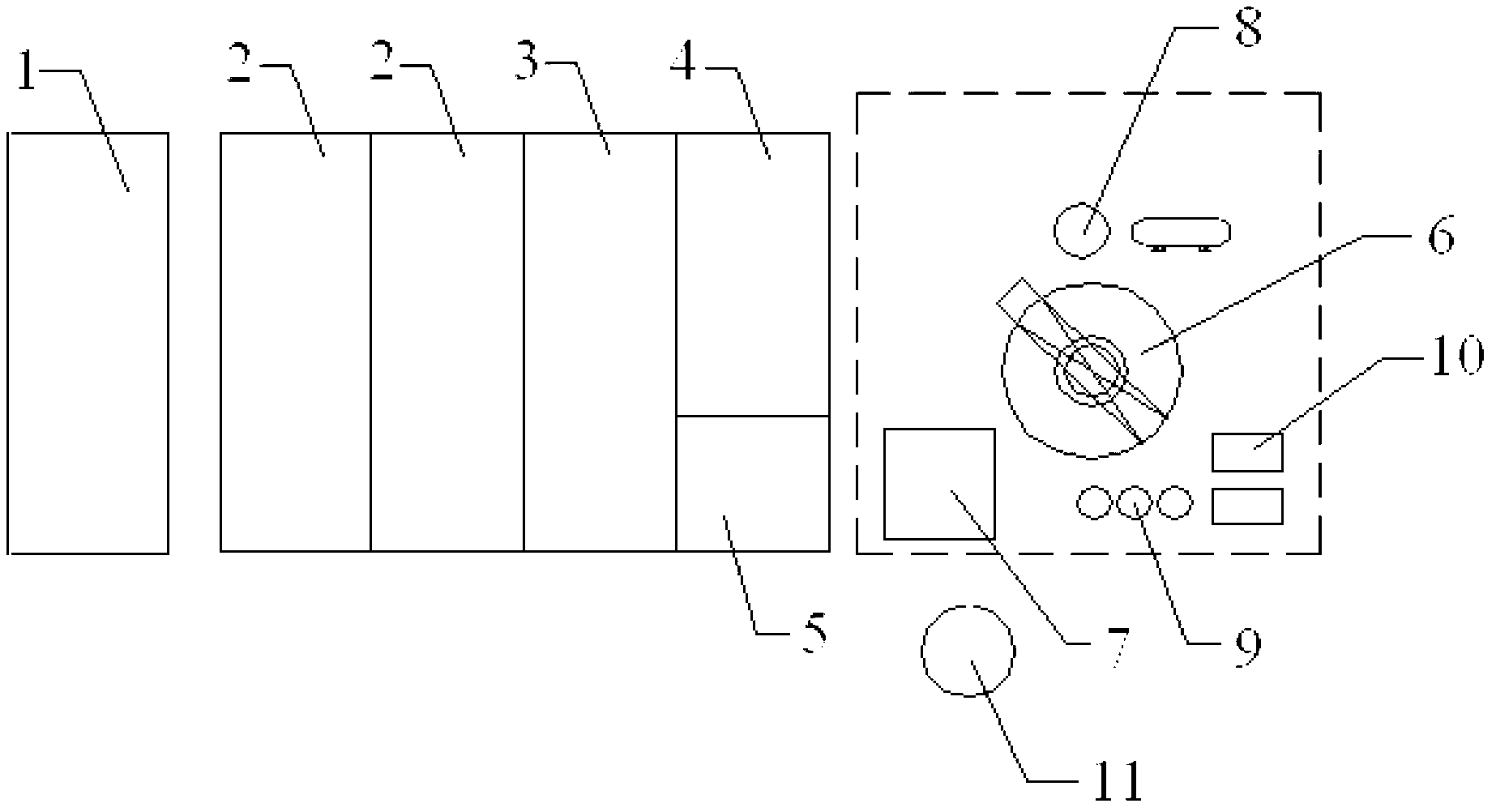

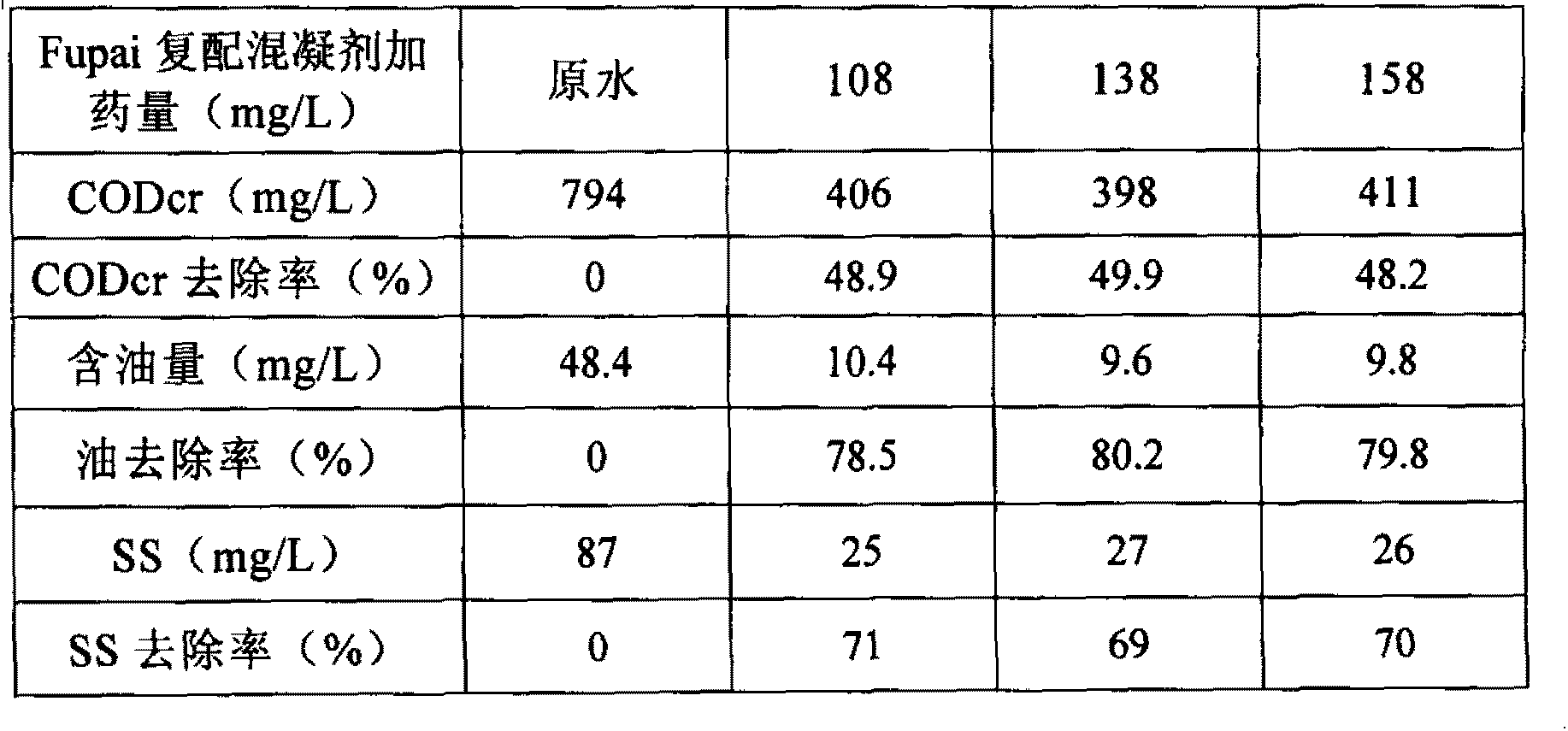

[0024] A system for treating heavy oil wastewater, its structure is as follows figure 1 As shown, it includes interconnected pretreatment unit, biochemical treatment pool and filtration unit. The pretreatment unit includes a grease trap 2 , a regulating tank 3 and a clean water tank 4 connected in sequence, and a slag tank 5 is also connected to the side of the clean water tank 4 . The grease trap 2 communicates with the regenerated waste water pool 1 containing heavy oil containing waste water. Fupai compound coagulant can be added in the adjustment tank 3. Inorganic coagulants that can be used include polyaluminum chloride, polyferric sulfate, polysilicon aluminum chloride, polysilicon aluminum sulfate or polysilicon ferric sulfate, and organic coagulants include polyacrylamide, dimethyl propyl ammonium chloride . A submersible mixer is installed at the bottom of the clear water pool, and the hydraulic retention time (HRT) in the pool is controlled to be 8-9 hours, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com