Molding drawing die of U-shaped elliptical or approximately elliptical condensation pipe, and machining method of molding drawing die

A technology that approximates an ellipse and a condenser tube. It is applied in the direction of wire drawing dies, etc., which can solve the problems of low efficiency, difficulty in threading, and large tolerance of cross-section dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

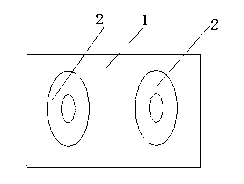

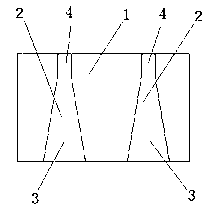

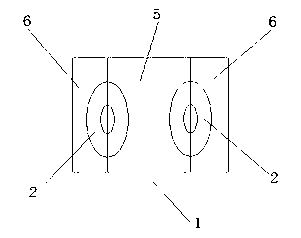

[0008] Include forming drawing die 1 among the figure, it is characterized in that: two drawing die holes 2 are opened on forming drawing die, two drawing die holes are located on the same horizontal line, and the distance between two drawing die holes is equal to U-shaped ellipse condensation pipe The distance between the two condensation pipes, the entrance section 3 of the die hole is an elliptical tapered section in cross section, the end of the entrance section is smoothly connected with an outlet shaping section 4, and the shaping section is an ellipse straight pipe section. It is characterized in that: the taper of the elliptical conical section with an elliptical cross section is 8.1 degrees, the minor axis length at the entrance of the elliptical conical section is greater than the diameter of the round pipe, the conical length is 24mm, and the length of the ellipse-shaped straight section is 6mm . It is characterized in that the cross-section of the elliptical straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com