Beneficiation method of low-grade copper, cobalt and nickel sulphide ore

A beneficiation method and a technology for sulfide ore, which are applied in the field of beneficiation of low-grade copper-cobalt-nickel sulfide ores, and can solve the problems of consuming flotation reagents, failing to realize beneficiation and separation, and affecting the recovery rate of target elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

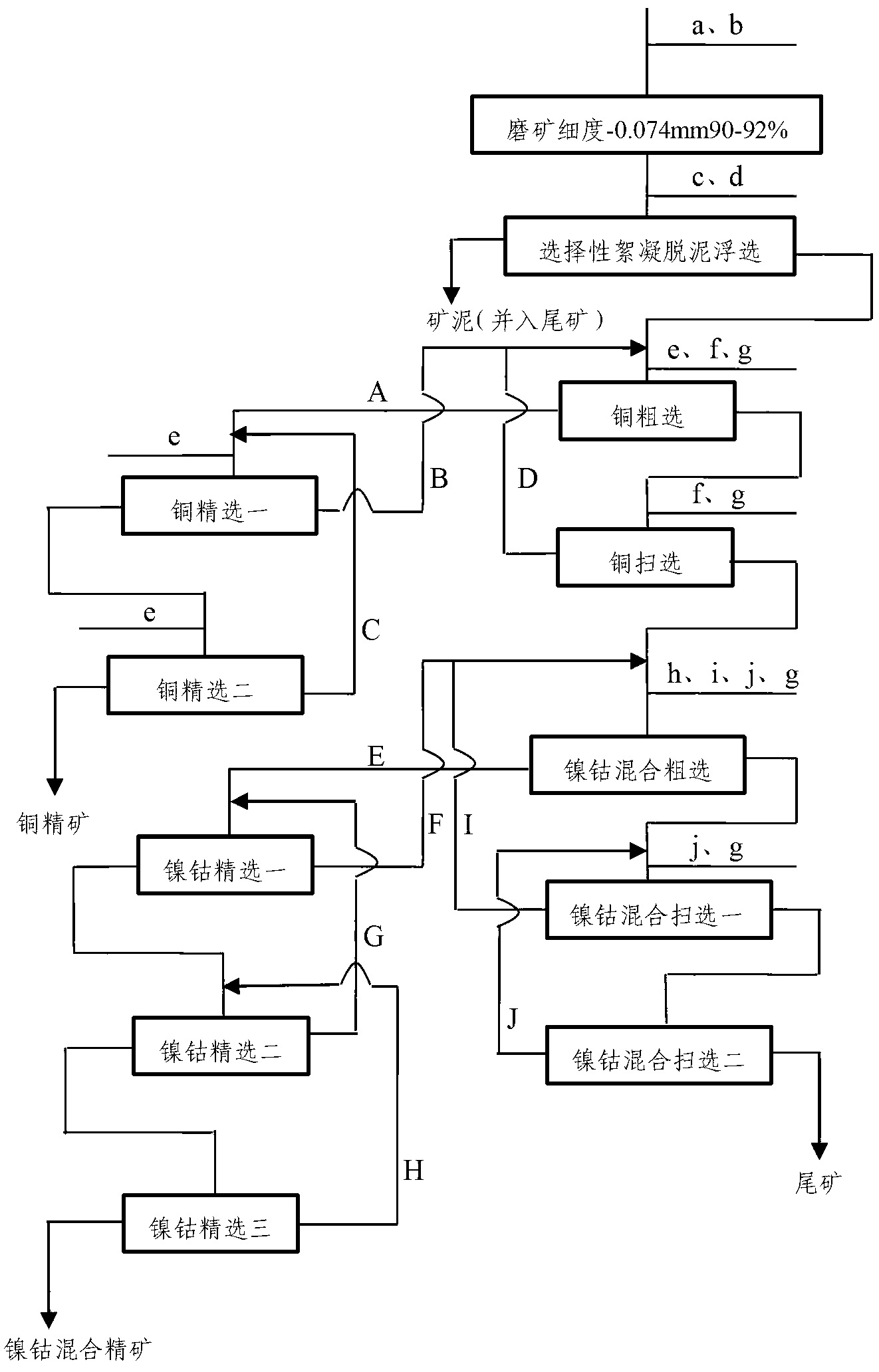

[0026] Example 1: Put the crushed raw ore and water into a ball mill at a ratio of 1:1 for grinding operation until the grinding fineness of the grinding product is -0.074mm, accounting for 91%. Sludge dispersing flocculant sodium hexametaphosphate and slime flotation collector mixed amine (based on raw ore dry ore weight, the same below), the dosage is 900g / t and 45g / t respectively, after selective flocculation, desliming and flotation Separation, the floating slime (foam product) is merged into the final tailings, and the product in the tank is subjected to copper roughing operation. Add 1250g / t of adjusting agent lime, stir for 4 minutes, adjust the pH value of the slurry to 10-11, then add 22g / t of copper collector Z-200 and 12g / t of BK-201 in sequence, and carry out rough copper separation ; Copper rougher concentrate enters copper beneficiation first operation, and copper rougher tailings undergoes copper scavenging operation. Add lime in an amount of 225g / t, stir for 4...

Embodiment 2

[0027] Embodiment 2: according to figure 1 The embodiment of the technological process of the present invention, the test steps, process parameters, and medicament system are exactly the same as those in Example 1. The specific technical indexes of embodiment 1 and embodiment 2 of the present invention are shown in Table 1.

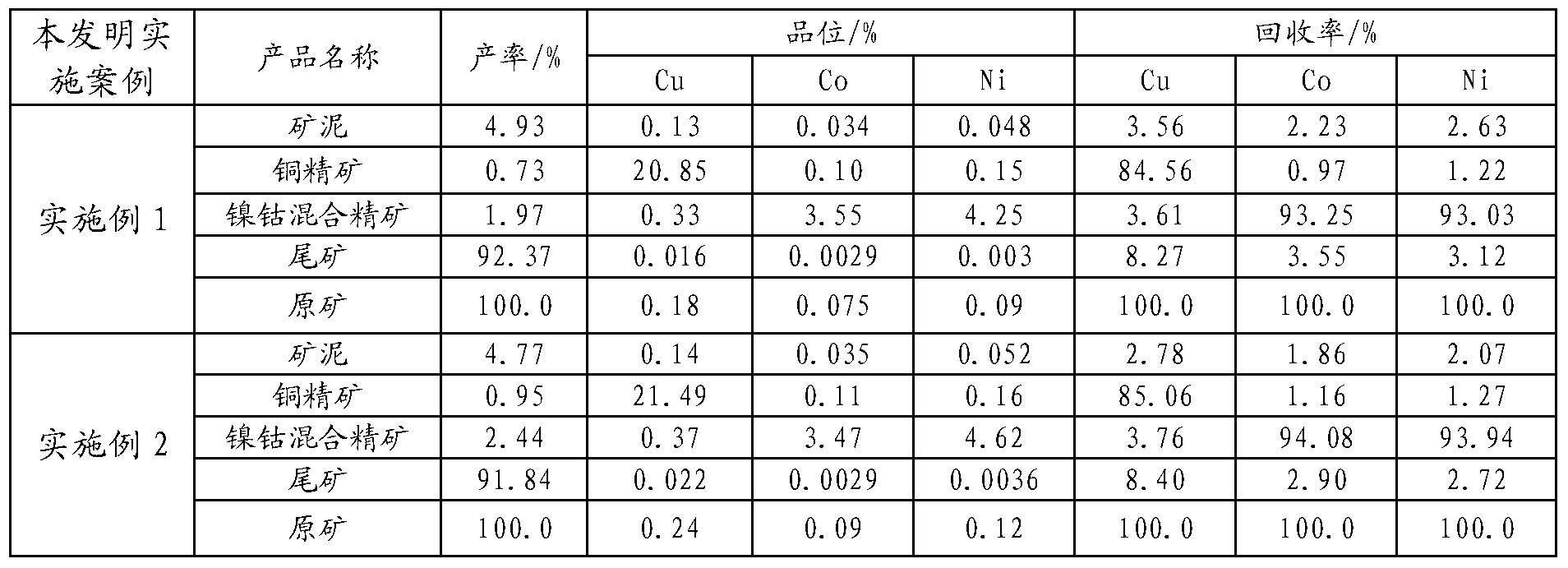

[0028] Shown by the implementation situation of embodiment 1 and embodiment 2 embodiment shown in table 1, adopt the inventive method, embodiment 1 contains Cu0.18%, Ni0.09%, Co0.075% in raw ore, can obtain copper grade Copper concentrate with 20.85% and 85.56% copper recovery rate, nickel-cobalt mixed concentrate with 3.55% cobalt grade and 4.25% nickel grade, 93.25% cobalt recovery rate and 93.03% nickel recovery rate; Example 2 contains Cu0.24 in the raw ore %, Ni0.12%, obtained a copper concentrate with a copper grade of 21.49% and a copper recovery rate of 85.06%, a nickel-cobalt mixed concentrate with a cobalt grade of 3.47% and a nickel grade of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com