6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

A technology of ylhexyl hydroxamic acid and ylhexyl hydroxamic acid salt, which is applied in the field of 6-aryl amidohexyl hydroxamic acid collector and its preparation and application, and can solve the problems of amide bond breaking, easy hydrolysis, and acid chloride toxicity Large and other problems, to achieve the effect of strong chelation ability, short reaction time, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

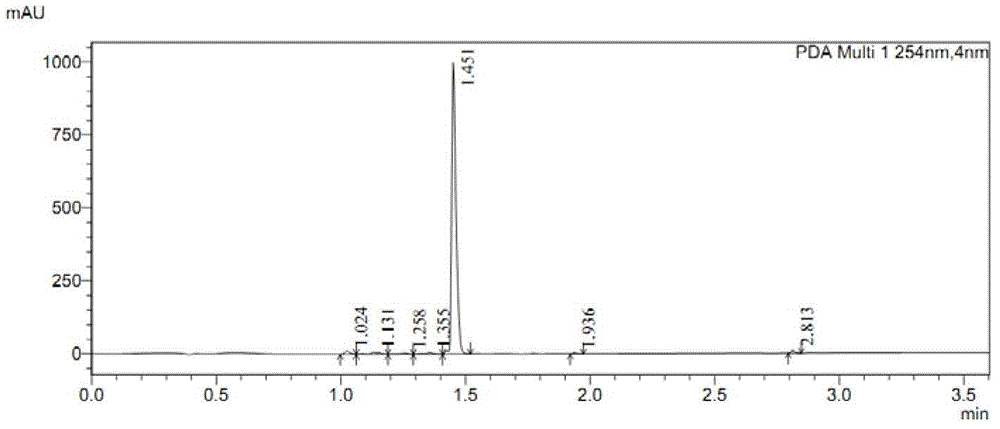

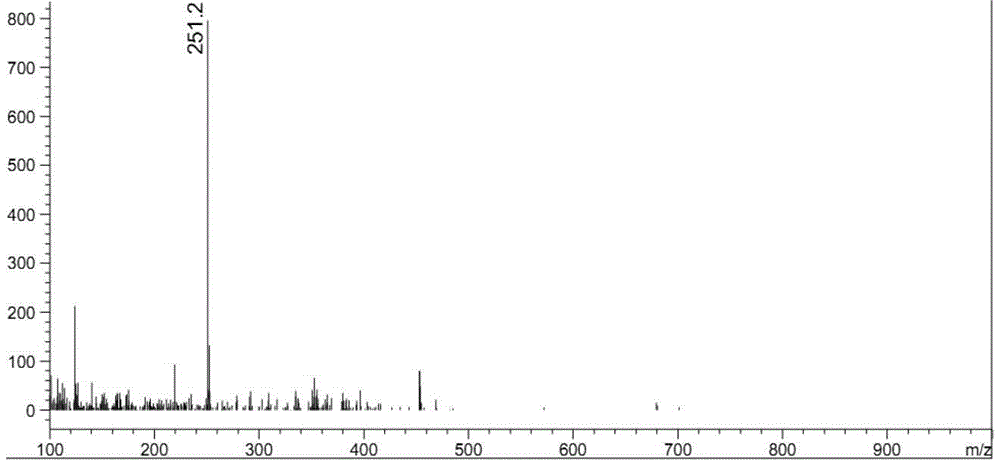

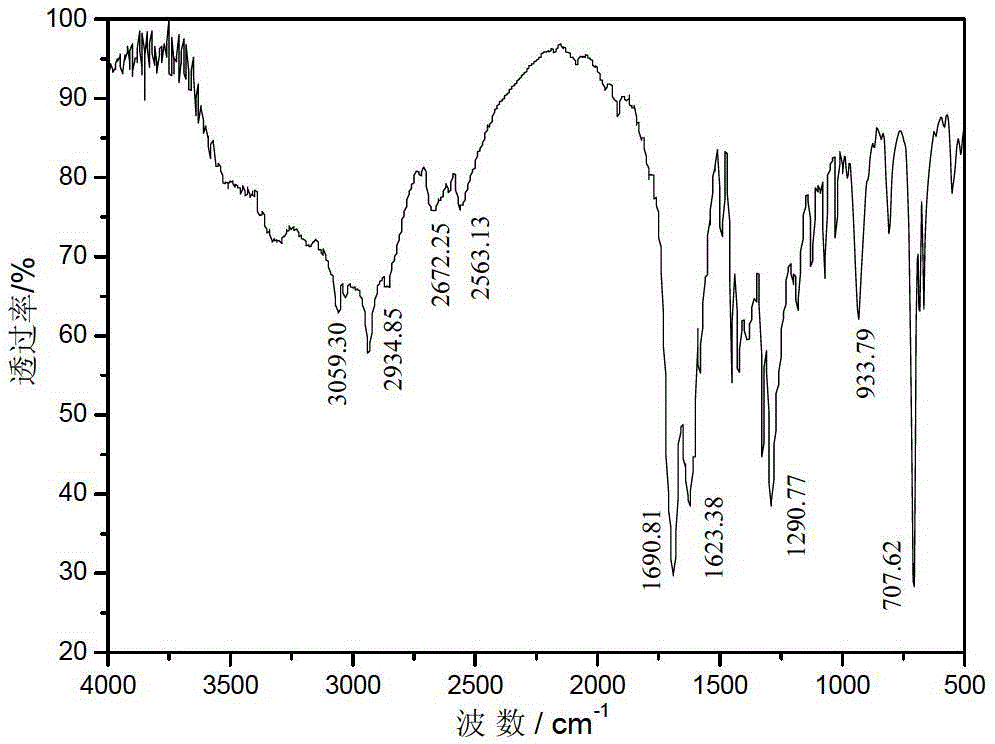

[0037] Add 11.32 parts of caprolactam with a purity of 99% and 6.95 parts of hydroxylamine hydrochloride with a purity of 99% into the reactor, add 34.64 parts of benzene or toluene as a solvent, heat to 80-110°C under stirring, react for 1-4 hours, and distill The solvent is recovered; then 12.21 parts of benzoic acid are added into the above-mentioned reactor, heated to 100-160° C. under stirring, and reacted for 4 hours to obtain the required 6-benzamide hexyl hydroxamic acid product. Liquid chromatography analysis shows that the purity of 6-benzamide hexyl hydroxamic acid is 95.3% (see figure 1 ), the yield was 92.4%. MS detected by mass spectrometry: 251.2 (see figure 2 ); Infrared spectrum see image 3 , 3025cm -1 It is N-H and O-H stretching vibration; 2934cm -1 It is saturated C-H stretching vibration; 1690cm -1 It is C=O stretching vibration; 1623cm -1 is the stretching vibration of a secondary amide; 1582cm -1 It is C-N bending vibration; 1452cm -1 C=C stret...

Embodiment 2

[0039] Embodiment 2: the application of 6-benzamide hexyl hydroxamic acid in tungsten ore flotation

[0040] A scheelite tailings containing WO 3 0.58%, grinding fineness -200 mesh accounted for 80%, using 1500g / t sodium carbonate to adjust pH value, 500g / t water glass as dispersant, after a rough separation operation, tungsten coarse concentrate was obtained. The flotation results of benzamide hexyl hydroxamic acid and benzyl hydroxamic acid are shown in Table 1. The results showed that 6-benzamide hexyl hydroxamic acid combined with oxidized paraffin soap 731, compared with benzyl hydroxamic acid, tungsten concentrate WO 3 The recovery rate increased by 2.60 percentage points.

[0041] Table 1 Flotation conditions and results of tungsten ore

[0042]

Embodiment 3

[0043] Example 3: Application of 6-benzamide hexyl hydroxamic acid in bauxite flotation

[0044] A bauxite containing Al 2 o 3 65.26%, SiO 2 10.43%, grinding fineness -200 mesh accounts for 80%, using 2500g / t of sodium carbonate to adjust the pH value, 50g / t of sodium hexametaphosphate, after a roughing operation, to obtain aluminum rough concentrate, 6-Benzene The flotation results of amidohexyl hydroxamic acid and oleic acid are shown in Table 2. The results showed that the combination of 6-benzamide hexyl hydroxamic acid and oleic acid, compared with benzyl hydroxamic acid, the aluminum concentrate Al 2 o 3 The recovery rate increased by 3.13 percentage points, and the aluminum-silicon ratio A / S increased by 0.44.

[0045] Table 2 Bauxite ore flotation conditions and results

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com