W-shaped flame boiler gap type OFA (over fire air) device arranged above arch wing wall

A gap-type, burn-out air technology, applied in the direction of combustion methods, combustion equipment, non-flammable liquid/gas transportation, etc., can solve the problem of high content of combustibles in NOx emission fly ash, not all four-corner burners can be put into operation, water-cooled wall To prevent tearing and other problems, to achieve the effect of preventing water wall tearing, reducing fly ash combustible content, and uniform heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

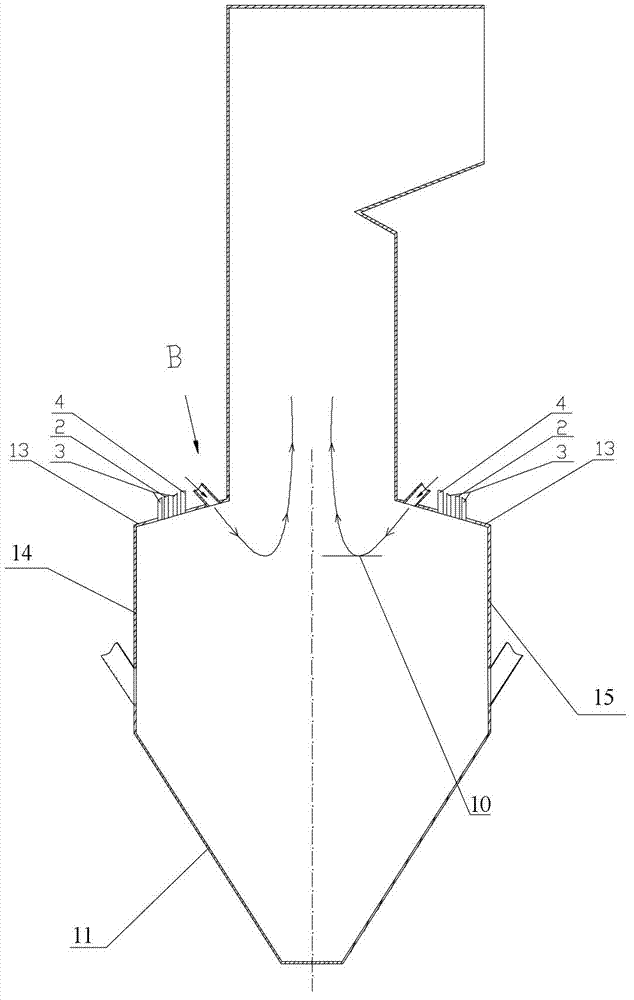

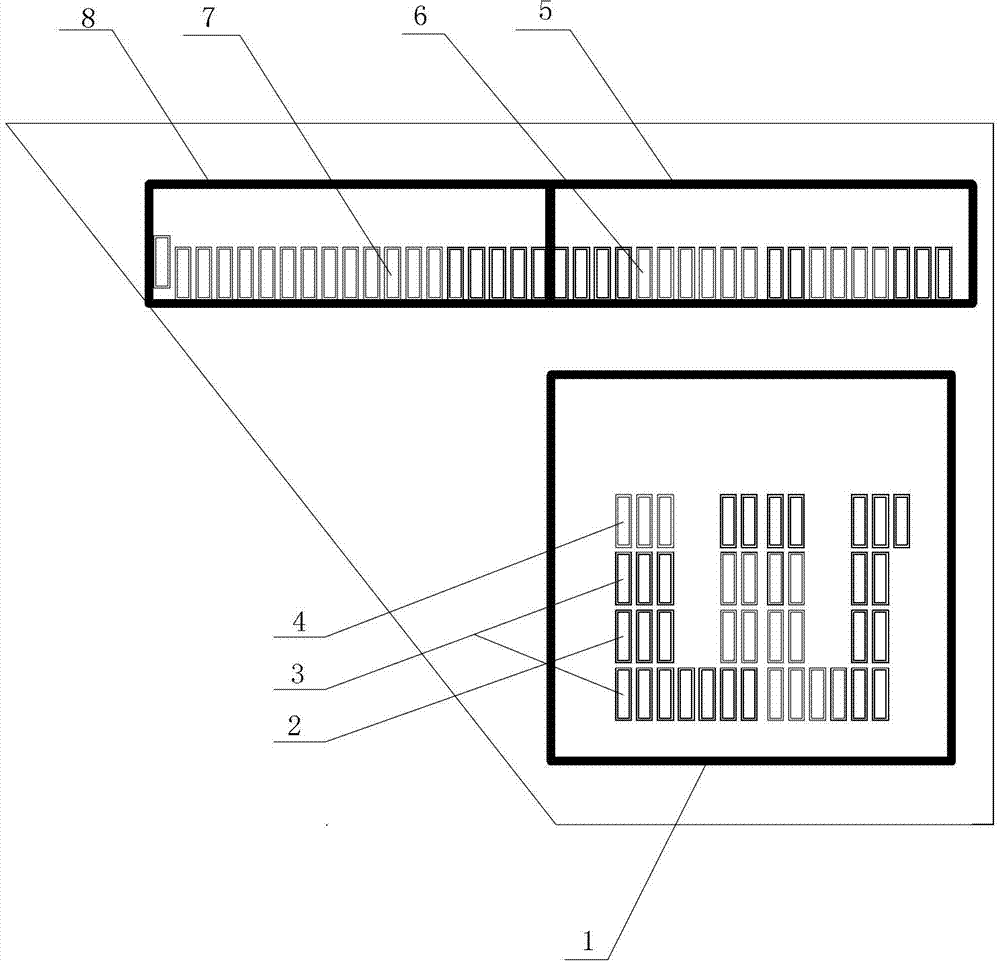

[0009] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the W-shaped flame boiler of this embodiment includes a furnace body composed of a lower furnace body 11, an upper furnace body 12 and two furnace arches 13, a plurality of primary air nozzles 4, a plurality of exhaust gas nozzles 2, a plurality of A secondary air nozzle 3, a plurality of slit-type arched burn-off air nozzles 6 and two main burner bellows 10, the lower furnace body 11 is composed of a front wall 14, a rear wall 15, two side walls 16 and four wing walls 17, a plurality of secondary air nozzles 3 are divided into two groups, two groups of secondary air nozzles 3 are symmetrically arranged along the center line of the furnace body, and a group of secondary air nozzles are arranged in parallel on each furnace arch 13 along its length direction 3. A plurality of secondary air nozzles 3 are all connected to the lower furnace of the lower furnace body 11. Two adjacent second...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 2 Describe this embodiment, the cross section of the slot-type wing wall overburning air nozzle 7 of this embodiment is a rectangle with an aspect ratio of (5-7):1. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 Describe this embodiment, the distance between the overburning air nozzle 6 on the slit arch and the corresponding primary air nozzle 4 in this embodiment is 1-2m, the advantage of this structure is that the distance between the overburning air and the primary air is relatively long, It will not be mixed with the primary air from the downward injection, so as to ensure the staged combustion and reduce NOx. At the same time, the exhaust air is fed into the lower furnace to ensure the oxygen required for the combustion of pulverized coal and promote the combustion of pulverized coal. Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com