An automobile constant velocity drive shaft sheath driven bearing

A constant-velocity drive shaft and sheath technology, used in shafts and bearings, needle roller bearings, roller bearings, etc., can solve the problems of complex raceway processing technology, wear of raceways and steel balls, and damage to organizational streamlines. To achieve the effect of compact structure, good sealing performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

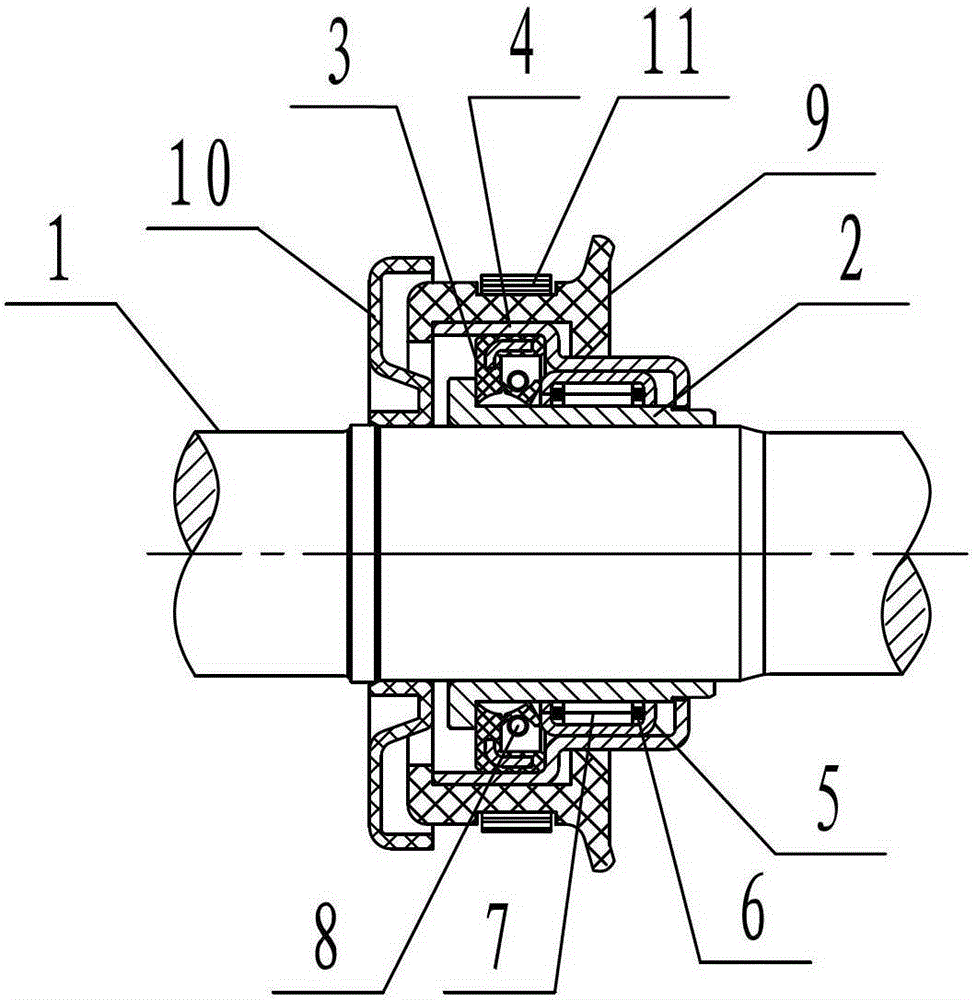

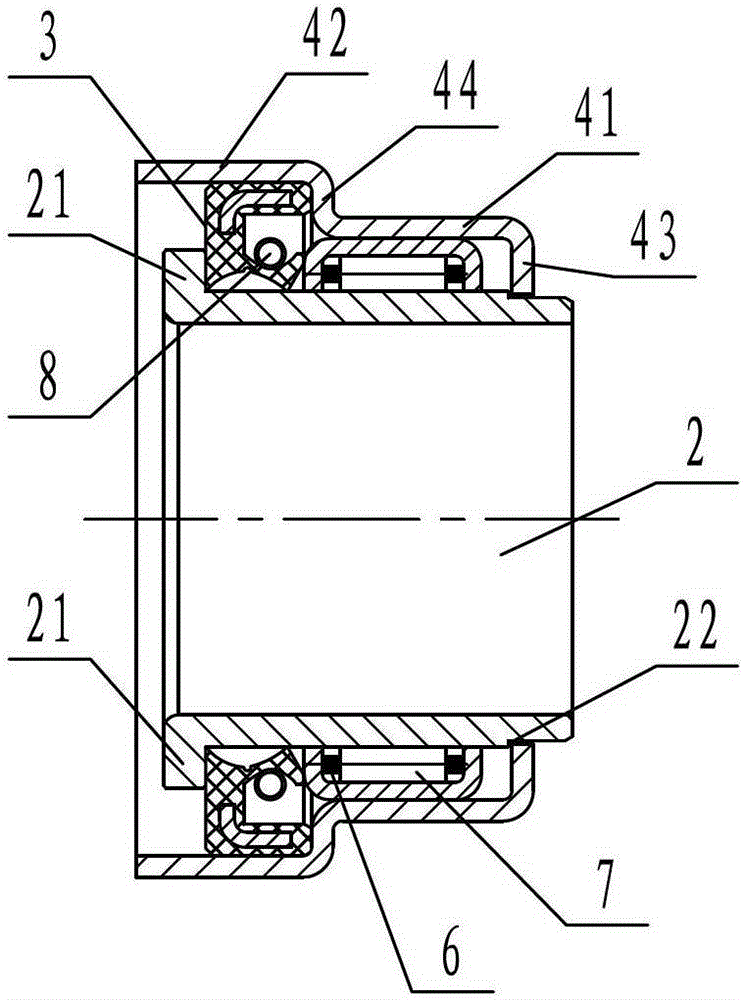

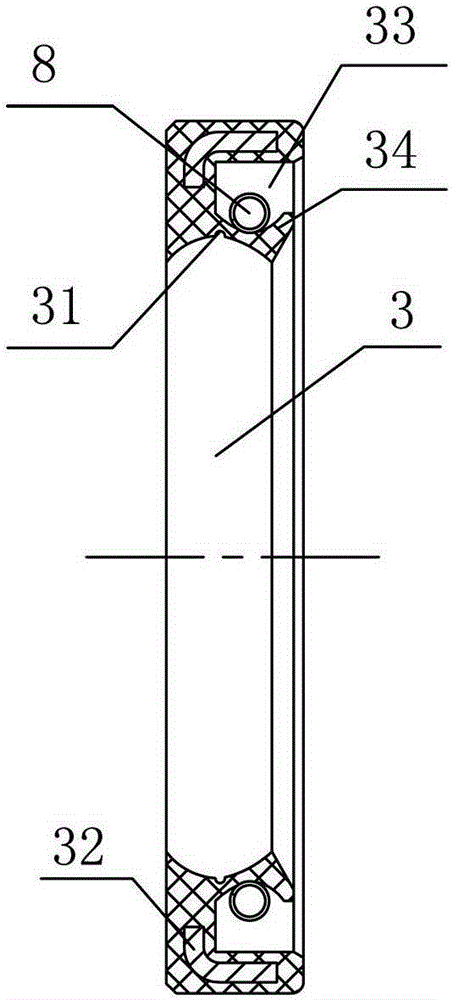

[0025] Such as Figures 1 to 4 As shown, an automobile constant velocity drive shaft sheath driven bearing includes an inner ring 2 sleeved on the mandrel 1, an outer ring 5 sleeved on the outer wall of the inner ring 2, and the inner ring 2 and the outer ring 5 A number of needle rollers 7 are arranged between the inner ring 2 and the outer ring 5. There is a fairway for accommodating the needle rollers 7. The needle rollers 7 are constrained by the cage 6. There is a preventive inner ring 2 and the sealing assembly for oil leakage between the outer ring 5. The inner diameter of the inner ring 2 is in interference fit with the mandrel 1 . The fairway is a circle of grooves Ⅰ51 on the inner wall of the outer ring 5. The outer ring 5 and the grooves Ⅰ51 are preferably extruded at one time. The streamline of the tissue remains intact, and the mechanical properties such as torsion and strength of the parts are increased, with low cost and long life. specialty. One side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com