Large section steel billet girder type heating furnace bottom stepping device

A heating furnace and large-section technology, applied in heat treatment furnaces, furnaces, furnace types, etc., to achieve the effects of low manufacturing cost, simple and compact transmission structure, and reduction of daily inspection and maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

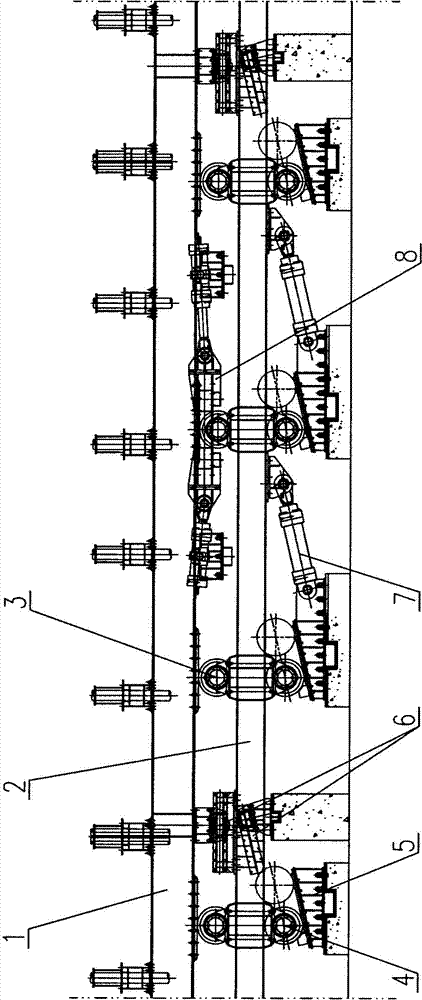

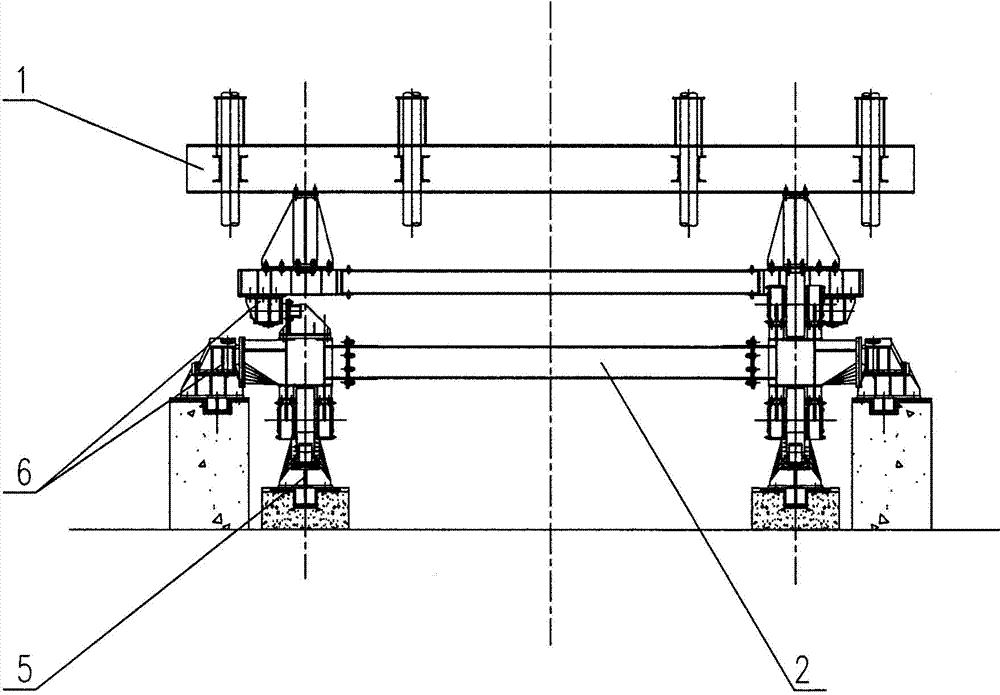

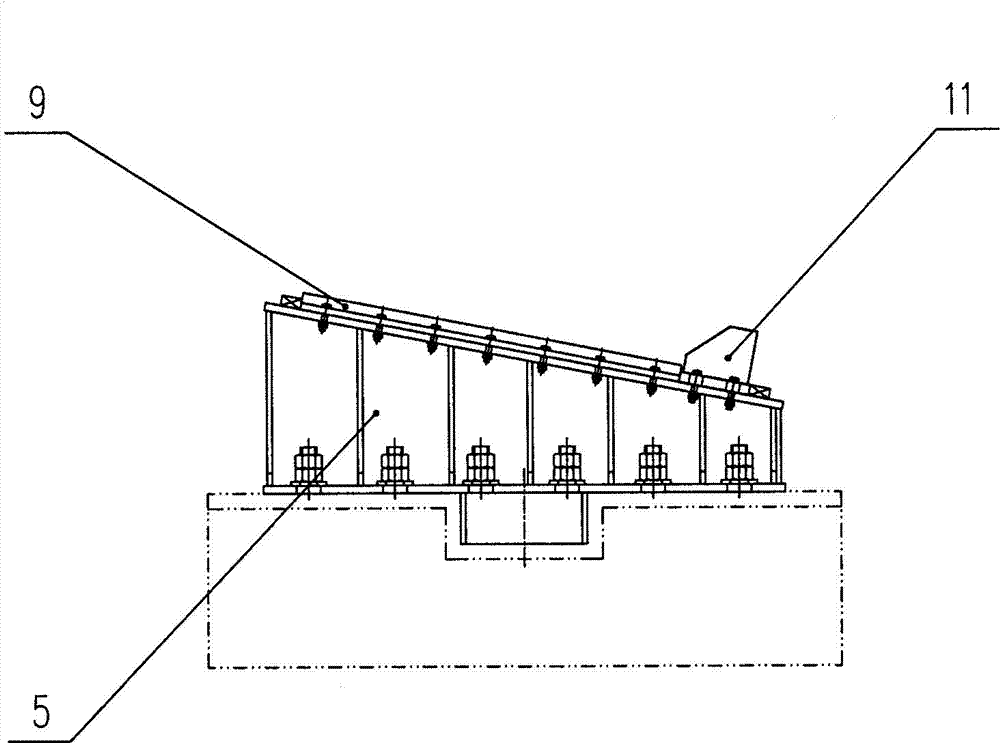

[0022] The bottom walking device of the large-section billet beam heating furnace of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See Figure 1 to Figure 7 , the walking device at the bottom of the large-section billet beam heating furnace of the present invention is used to support the functional components of the heating furnace, realize the loading of steel at the furnace tail of the heating furnace, and move the billet loaded into the furnace from the furnace tail to the furnace head step by step , out of the furnace and sent to rolling line or heat treatment line for processing. It is composed of: translation frame 1, lifting frame 2, translation roller 3, lifting roller 4, inclined guide rail seat 5, translation and lifting frame lateral positioning guide wheel group 6, lifting drive device 7 and translation drive device 8, which can realize positive Circulation, reverse circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com