Tobacco paper filter stick combining bamboo fiber and preparation method of tobacco paper filter stick

A bamboo fiber and tobacco technology, applied in tobacco, smoke oil filter, application and other directions, can solve the problem of not completely solving the problem of waste disposal in tobacco production enterprises, can not solve the problem of reducing tobacco waste materials, not finding paper filter material and other problems , to achieve strong ability to remove tar and nicotine, improve the wettability of smoke, and realize the effect of visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

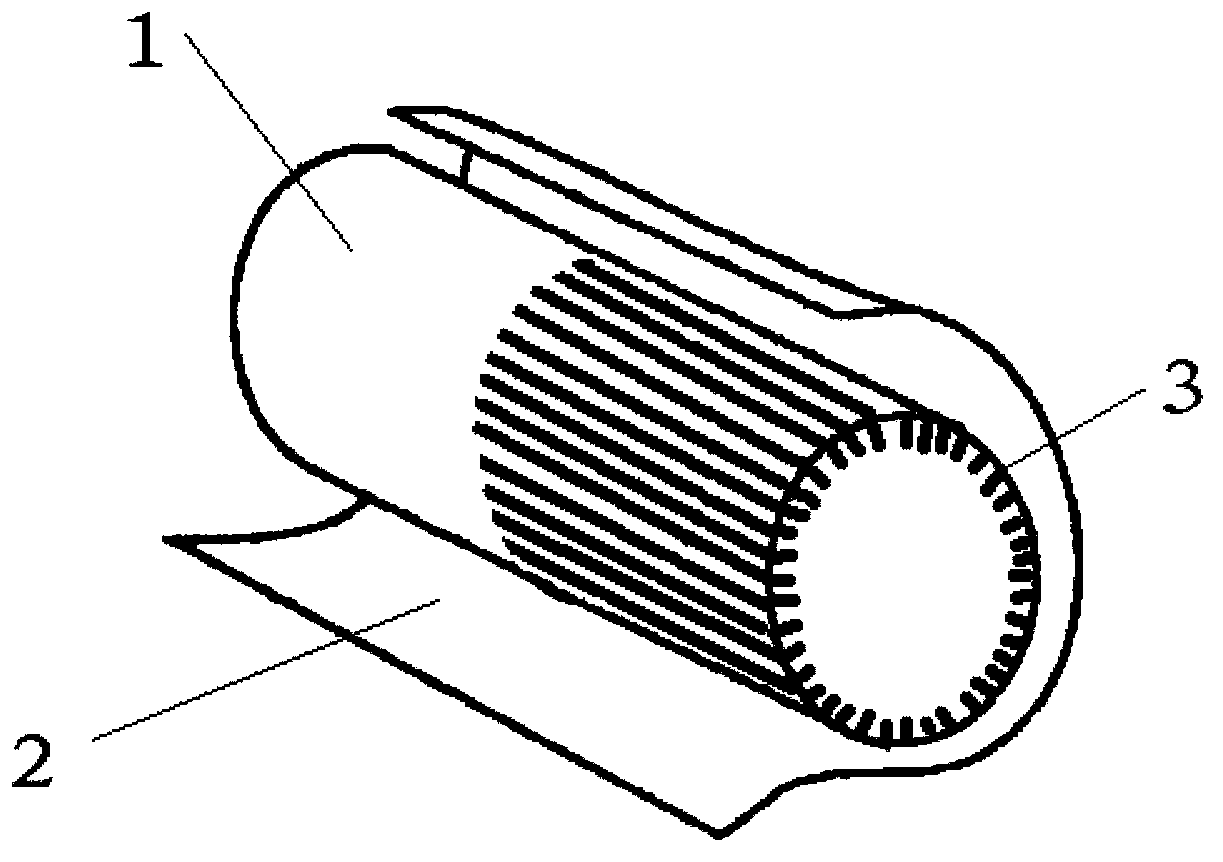

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of tobacco fiber filter rods with tobacco leaves and tobacco stems

[0044] S1. extracting the tobacco raw material to obtain the extract solution of the tobacco raw material and the solid slag of the tobacco raw material;

[0045] In this example, tobacco stems and water were extracted at a mass ratio of 1:7 at a temperature of 60°C and an extraction time of 100 minutes, and the extraction was repeated three times. Tobacco stem extract and tobacco stem solid slag obtained after treatment.

[0046] Tobacco leaves and water were extracted at a mass ratio of 1:10, the extraction temperature was 80°C, and the extraction time was 60 minutes, and the extraction was repeated three times. Tobacco leaf extract and tobacco leaf solid slag obtained after treatment.

[0047] S2. Refining the solid slag of the tobacco raw material to obtain tobacco fiber pulp;

[0048] The refining process in this embodiment refers to the refining process in the existing to...

Embodiment 2

[0052] Example 2 Preparation of fiber filter rods with tobacco dust and tobacco fragments

[0053] S1. Extracting raw materials to obtain raw material extracts and solid slag of raw materials;

[0054] Tobacco leaves and water were extracted at a mass ratio of 1:10, the extraction temperature was 80°C, and the extraction time was 60 minutes, and the extraction was repeated three times. Tobacco leaf extract and tobacco leaf solid slag obtained after treatment.

[0055] According to the mass ratio of solid to liquid of 1:10, the smoke fragments and water were separated, the extraction temperature was 75°C, and the extraction time was 60 minutes. The smoke chip extract and the smoke chip solid slag obtained after treatment.

[0056] S2. Refining the solid slag of the tobacco raw material to obtain tobacco fiber pulp;

[0057] The refining process in this embodiment refers to the refining process in the existing tobacco sheet.

[0058] S3. Blending tobacco fiber pulp and bambo...

Embodiment 3

[0061] Example 3 Preparation of Tobacco Fiber Filter Sticks with Tobacco Dust and Bamboo Fiber

[0062] S1. extracting the tobacco raw material to obtain the extract solution of the tobacco raw material and the solid slag of the tobacco raw material;

[0063] Tobacco leaves and water were extracted at a mass ratio of 1:10, the extraction temperature was 80°C, and the extraction time was 60 minutes, and the extraction was repeated three times. Tobacco leaf extract and tobacco leaf solid slag obtained after treatment.

[0064] S2. Refining the solid slag of tobacco raw material to obtain tobacco fiber pulp; commercially available bamboo fiber.

[0065] The refining process in this embodiment refers to the refining process in the existing tobacco sheet.

[0066] S3. Tobacco fiber pulp and bamboo fiber are blended in a mass ratio of 1:2, sheeted to obtain a tobacco fiber paper base, pressed for 5 minutes at a pressure of 0.4 MPa, and then placed at a temperature of 105 ° C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com