A kind of preparation method of lateral graphene pin junction

A graphene, lateral technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulty in realizing graphene PIN junctions, and achieve the effects of easy implementation, simple process, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

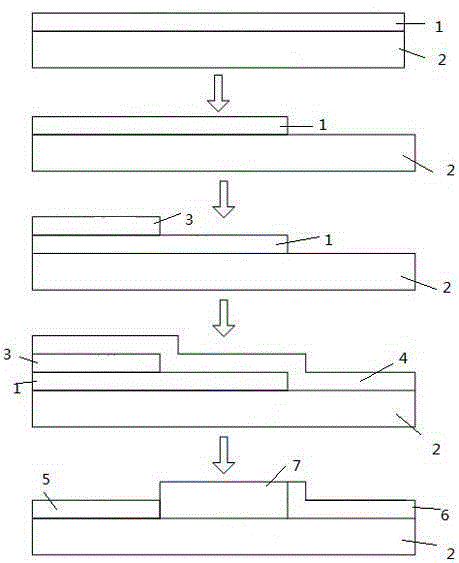

[0020] Depend on figure 1 As can be seen from the shown flow chart, the preparation steps of Example 1 are:

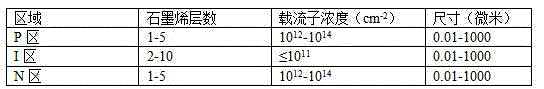

[0021] In the first step, the underlying graphene is grown on the SiC substrate 2 by SiC pyrolysis, the doping type of the underlying graphene is n-type, and the doping concentration is 10 12 -10 14 cm -2 controllable.

[0022] In the second step, photolithography is used to retain the region that needs to retain n-type doping on the bottom graphene, and other regions are removed by oxygen plasma etching; the region that needs to retain n-type doping is to be used as N region 5 and I region 7, the removed area is the area to be used as the P area 6.

[0023] The third step is to precipitate Si on the bottom graphene in the sample obtained in the second step above, which needs to be an n-type region 3 N 4 Blocking layer 3.

[0024] The fourth step is to transfer the p-type transfer graphene 4 grown by CVD to the sample obtained in the third step. At this time, t...

Embodiment 2

[0028] Different from Example 1, the preparation steps of Example 2 are:

[0029] In the first step, the n-type bottom graphene 1 is grown on the SiC substrate 2 by the CVD method, and the bottom graphene is annealed in a hydrogen atmosphere, and the hydrogen atoms enter the interface between the bottom graphene and the SiC substrate 2, so that the bottom graphene Converted to p-type doping with a doping concentration of 10 12 -10 14 cm -2 controllable.

[0030] In the second step, photolithography is used to retain the region on the bottom graphene that needs to retain p-type doping, and other regions are removed by oxygen plasma etching; the region that needs to retain p-type doping is to be used as P region 6 and I region 7, the removed area is the area to be used as the N area 5.

[0031] In the third step, SiO is deposited on the region that needs to be p-type in the above-mentioned bottom graphene 2 Occlusion layer.

[0032] The fourth step is to transfer the n-ty...

Embodiment 3

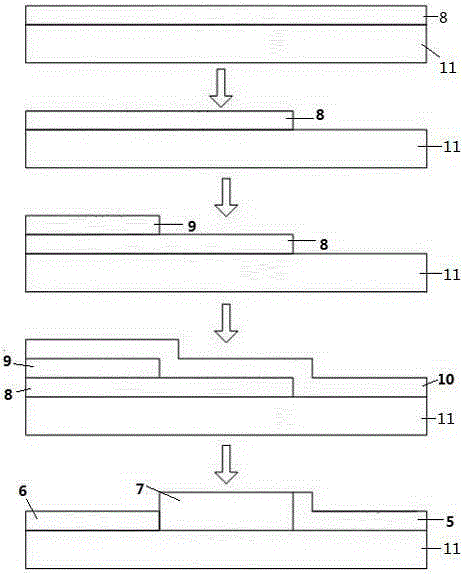

[0036] Depend on figure 2 It can be seen that, unlike Example 1 and Example 2, the specific preparation steps of this example are:

[0037] In the first step, the p-type bottom graphene 8 is grown on the Cu substrate by the CVD method; the p-type bottom graphene 8 is transferred to the Si substrate 11 with a doping concentration of 10 12 -10 14 cm -2 controllable.

[0038] In the second step, photolithography is used to retain the region on the bottom graphene that needs to be retained, and other regions are removed by oxygen plasma etching; the region that needs to retain p-type doping is to be used as P region 6 and I region 7 The area to be removed is the area to be used as the N area 5.

[0039] In the third step, an Au shielding layer 9 is deposited on the region of the bottom graphene that needs to be p-type.

[0040] The fourth step is to transfer the n-type graphene grown by CVD to the sample obtained in the third step. At this time, the surfaces of the shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com