Optical fiber ring temperature performance improvement method based on graphene and optical fiber ring

A temperature performance, graphene technology, applied in the field of optical fiber rings, can solve the problems of high proportion of graphene volume, unable to improve the thermal conductivity of optical fiber ring rubber, etc., to achieve easier control of doping concentration, simple operation, and lower temperature gradient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments.

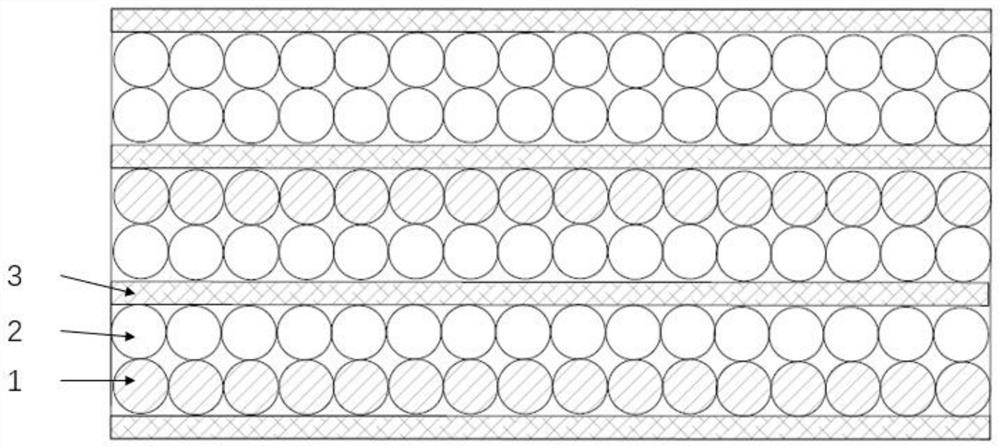

[0035] refer to figure 1 , a graphene-based optical fiber ring, using a graphene-based optical fiber ring temperature performance improvement method, comprising the steps of:

[0036] Step (1): Wrap a layer of graphene heat-conducting film 3 on the optical fiber surrounding ring tooling as the bottom heat-conducting layer;

[0037] Step (2): Use quadrupole symmetrical winding to wind the optical fiber ring, start with the bottom graphene heat-conducting film 3, and wrap a graphene heat-conducting film 3 every two layers of optical fibers as the middle heat-conducting layer:

[0038] (2.1) Divide the whole polarization maintaining fiber into left and right parts from the midpoint;

[0039] (2.2) Wrap a layer of fiber layer 1 in a clockwise direction around the outer periphery of the graphene heat-conducting film 3 with a part of it, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com