Disposable protective garment for nuclear industry and processing method after disposable protective garment is used

A treatment method and technology of protective clothing, applied in the field of protective clothing, can solve the problems of huge amount of waste disposal, expansion of the global environment, consumption of protective clothing, etc., and achieve the effect of benefiting soil unity, improving soil, and preventing skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, nuclear industry special lab coat and waste reprocessing thereof

[0026] Protective clothing is made of 60 g / m2 water-soluble polyvinyl alcohol spunlace nonwoven fabric, water-soluble polyvinyl alcohol sewing thread, water-soluble tape, zipper, etc. The protective clothing fabric can be completely dissolved in water.

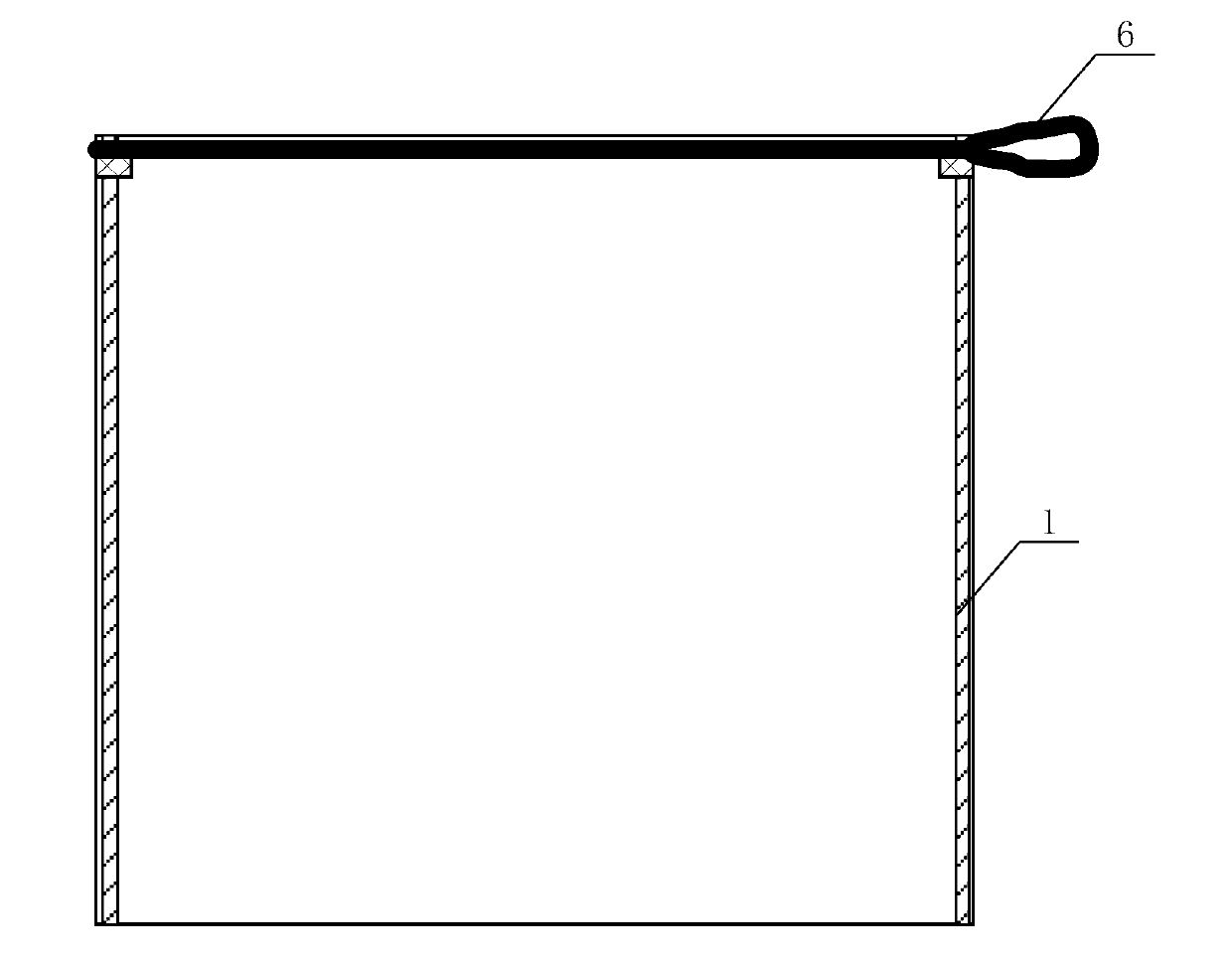

[0027] After being used and discarded, put it into a storage bag with a thickness of 0.04mm and a size of 0.8mX1m (such as figure 1 ), heat-sealing lines 1 are formed on both sides of the storage bag, and the drawstring 6 is tightened to seal.

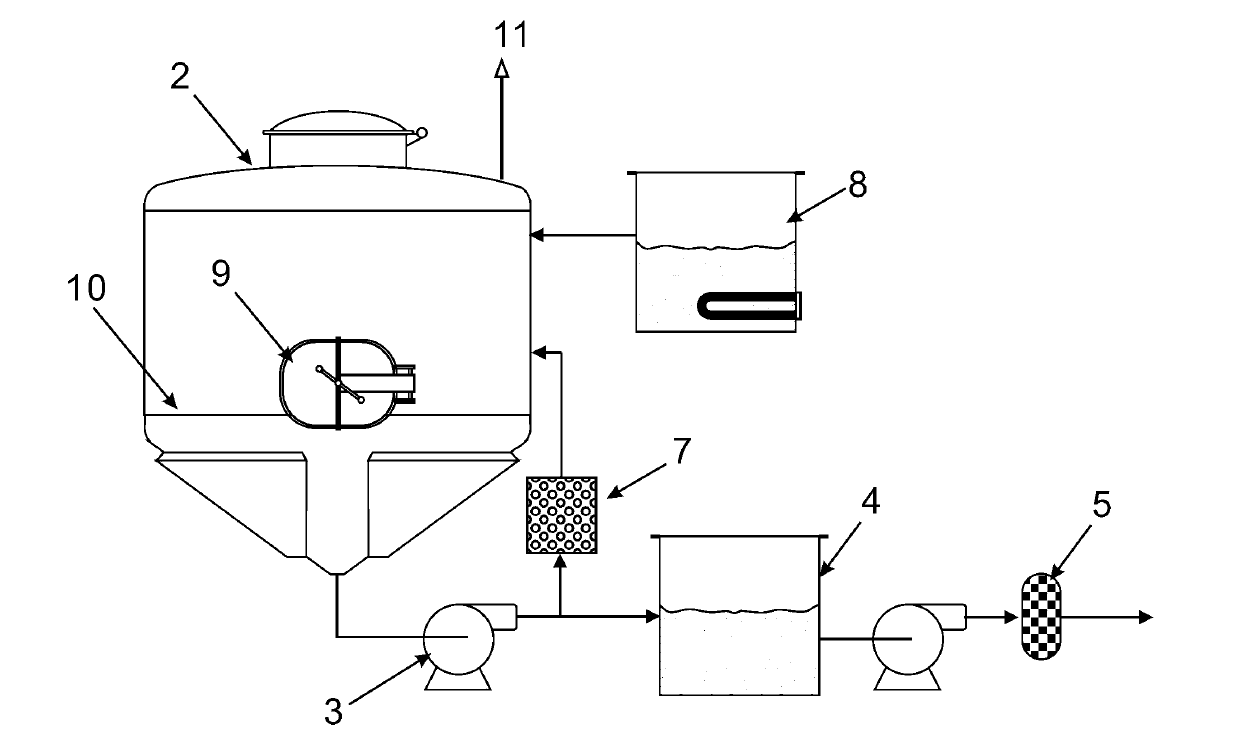

[0028] The discarded protective clothing, together with the storage bag, is put into the stainless steel melting furnace 2 (such as figure 2 ), dissolved in 95°C water while stirring, and after 1.5 hours, the aqueous solution was sent to the storage tank 4 by the delivery pump 3 for temporary storage, except for the insoluble matter such as Velcro. A very small amount of insoluble matter is bloc...

Embodiment 2

[0033] Embodiment 2, nuclear industry special work clothes and waste reprocessing thereof

[0034] Using 60 g / m2 water-soluble polyvinyl alcohol spunlace nonwoven fabric and 0.025mm water-soluble polyvinyl alcohol film, the two layers are composited together by ultrasonic waves to form a protective clothing fabric, and water-soluble polyvinyl alcohol sewing thread, Water-soluble tapes, zippers, water-soluble labels, etc., made into protective clothing. The protective clothing fabric can be completely dissolved in water.

[0035] After use and discarding, put it into a storage bag with a thickness of 0.04mm and a size of 1mX1m (such as figure 1 ), tighten the drawstring 6 to seal.

[0036] The discarded protective clothing, together with the storage bag, is put into a stainless steel melting furnace and dissolved in 95°C water while stirring. After 1.5 hours, the aqueous solution is sent to the storage tank by the delivery pump for temporary storage except for the insoluble mat...

Embodiment 3

[0041] Embodiment 3, special electric welding protective clothing for nuclear industry and its waste reprocessing

[0042] Using 130 g / m2 water-soluble polyvinyl alcohol spunlace nonwoven fabric, through two processes of flame-retardant impregnation and coating, a water-soluble biodegradable high-temperature heat-resistant and heat-resistant protective clothing fabric with a grammage of 300 g / m2 . The fabric, water-soluble polyvinyl alcohol sewing thread, water-soluble tape, zipper, water-soluble label, etc. are made into special protective clothing for maintenance and electric welding. The protective clothing fabric is 94% soluble in water.

[0043] After use and disposal, put it into a storage bag with a thickness of 0.04mm and a size of 1mX1m, and tighten the drawstring to seal it.

[0044] The discarded protective clothing, together with the storage bag, is put into a stainless steel melting furnace and dissolved in 95°C water while stirring. After 1.5 hours, the aqueous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter pore size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com