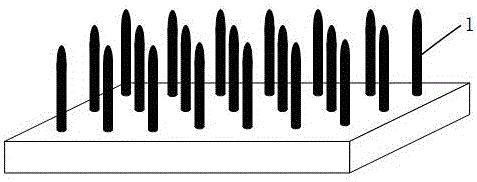

Nano-nickel rod array atomic force microscope tip characterization sample and its manufacturing method

An atomic force microscope and nanorod array technology, applied in scanning probe microscopy, scanning probe technology, measuring devices, etc., can solve the problems of poor consistency, high preparation cost, large size, etc., and reduce wear and preparation costs. Low, small feature size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

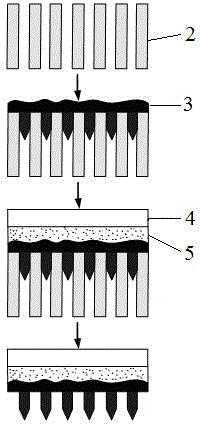

[0034] (1) Wash the high-purity aluminum film with a purity of 99.99% in acetone solution for 20 minutes, infiltrate 5% NaOH solution for 7 minutes to remove the oxide layer on the surface of the aluminum film, rinse it with distilled water, and then perform annealing treatment;

[0035] (2) At 0°C, put the high-purity aluminum film obtained in the previous step into C 2 h 5 OH and HClO 4 Perform constant-pressure chemical polishing in the mixed solution for 8 minutes to remove the oxide layer on the surface of the aluminum sheet and improve the flatness of the surface;

[0036] (3) Put the polished high-purity aluminum film into the anodizing device for the first anodic oxidation, the first anodic oxidation is 5min, the oxidation is carried out under constant pressure conditions, and the PAA template obtained after the primary oxidation is immersed in 6%H 3 PO 4 and 1.8% H 2 CrO 4 In the mixed solution, place it at 60°C for more than 2.5 hours to dissolve the barrier l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com