Method for monitoring COD (chemical oxygen demand) in fluorescent wastewater

A chemical oxygen demand, fluorescent wastewater technology, applied in the measurement of color/spectral characteristics, preparation of test samples, etc., can solve the problem that cannot meet the monitoring requirements of large-scale, fast, high-efficiency, energy-saving, environmental protection, and the occupation of return devices. Large space, large consumption of precious reagents, etc., to achieve accurate and reliable test results, less secondary pollution, and comparable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Verification of Oxidation Ability of Closed Tube Digestion Spectrophotometry for Determination of Chemical Oxygen Demand

[0025] Sodium acetate was used to prepare standard solutions with COD theoretical values of 1000 mg / L and 250 mg / L, respectively, and were determined by closed-tube digestion method, open-tube digestion method and national standard GB / T11914-1989 potassium dichromate method. The method of digestion spectrophotometry is as follows:

[0026] 1) Draw 2.5mL of homogeneous mixed water sample into the reaction tube, add 0.7mL of the above oxidant solution, add 4.8mL of the above composite catalyst, add 0.35mL of the above masking agent, and shake well;

[0027] 2) Place the above reaction tube in a digester at 160-165°C, cover the reaction tube, digest for 10-15 minutes and take it out;

[0028] 3) After taking it out, cool it in the air, add 2.5mL deionized water, mix well, and then cool it to room temperature;

[0029] 4) Then pour it into...

Embodiment 2

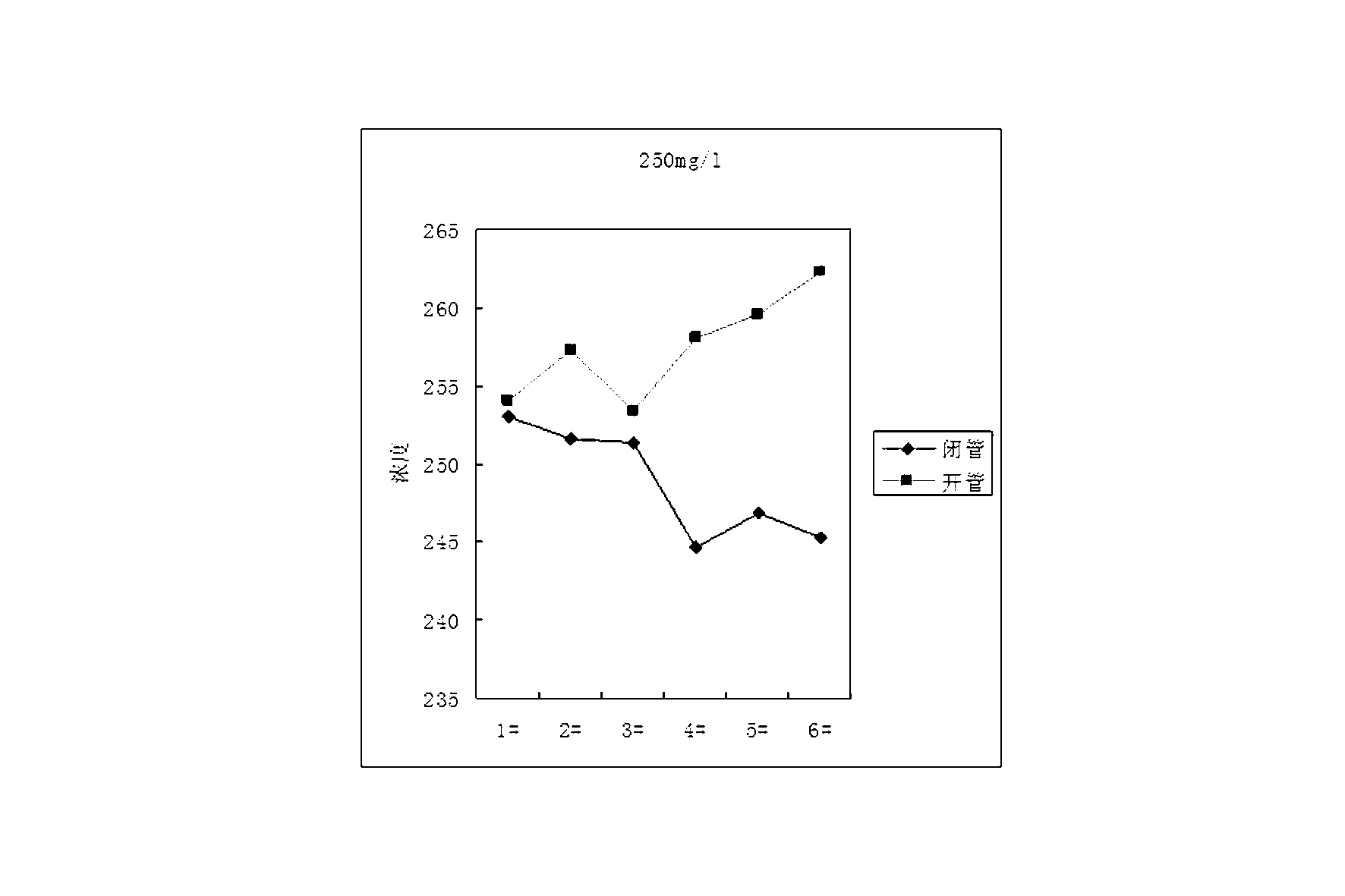

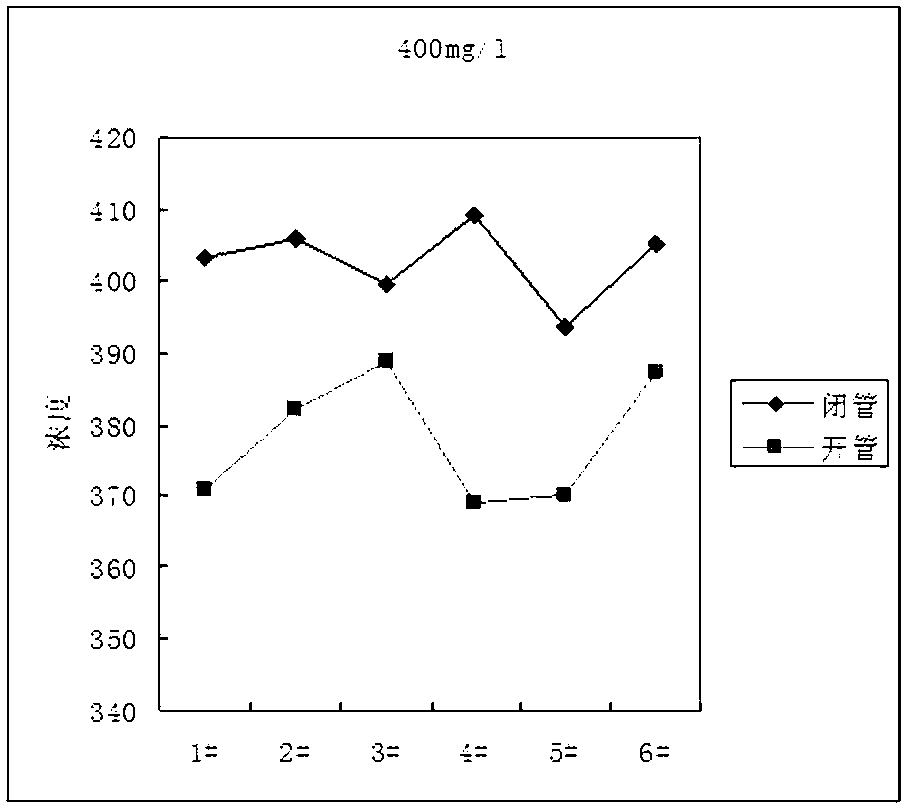

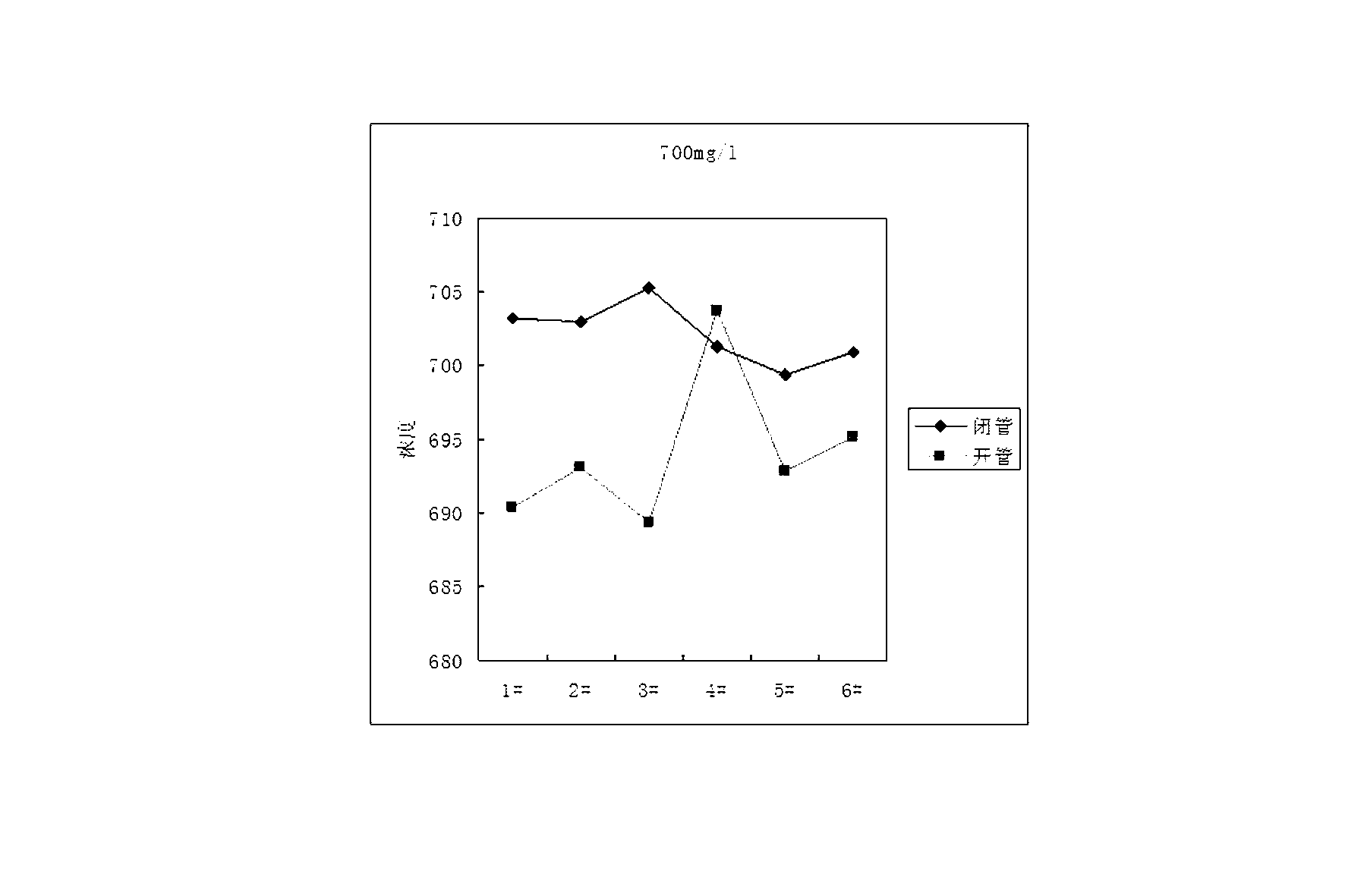

[0034] Example 2 The comparison of standard solutions with different concentration levels using the closed tube digestion method and the open tube digestion method to test COD

[0035] Potassium hydrogen phthalate was used to prepare standard solutions with COD concentrations of 250 mg / L, 400 mg / L, 700 mg / L and 1000 mg / L, respectively. Potassium hydrogen phthalate standard solution: Weigh 0.8502 g of potassium hydrogen phthalate that was baked at 105°C to constant weight, dissolve in water, transfer to a 1000 mL volumetric flask, dilute to the mark and mix well, this solution is equivalent to 1000mg / LO 2 The COD of the above-mentioned potassium hydrogen phthalate standard solution was measured by closed-tube digestion method and open-tube digestion method respectively.

[0036] The closed-tube digestion method is as follows:

[0037] 1) Draw 2.5mL homogeneous mixed water sample into the reaction tube, add 0.7mL oxidant solution, add 4.8mL composite catalyst, add 0.35mL maski...

Embodiment 3

[0043] Embodiment 3 Using the closed-pipe digestion method of the present invention, the open-pipe digestion method and the national standard potassium dichromate method to monitor the comparison of fluorescent wastewater at the company's total sewage discharge outlet and workshop outlet

[0044] Fluorescent wastewater from the total sewage discharge outlet and the workshop outlet were collected in five different time periods. The components of the fluorescent wastewater mainly include fluorescent agents, mineral oil, kerosene, surfactants and additives and other macromolecular chain substances. Simultaneously Closed tube digestion method, open tube digestion method and standard potassium dichromate method were used to determine the COD value in wastewater. The results are shown in Table 2 below: From the data in Table 2, it can be seen that the data measured by the closed-tube method is more comparable to the national standard potassium dichromate method, and the closed-tube d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com