Optical lens

An optical lens and lens technology, applied in the field of optical lenses, can solve problems such as increasing design difficulty, excessive deviation, and affecting product uniformity, and achieve the effects of reducing design difficulty, reducing distance, and reducing light mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Apply optical lens to TV backlight

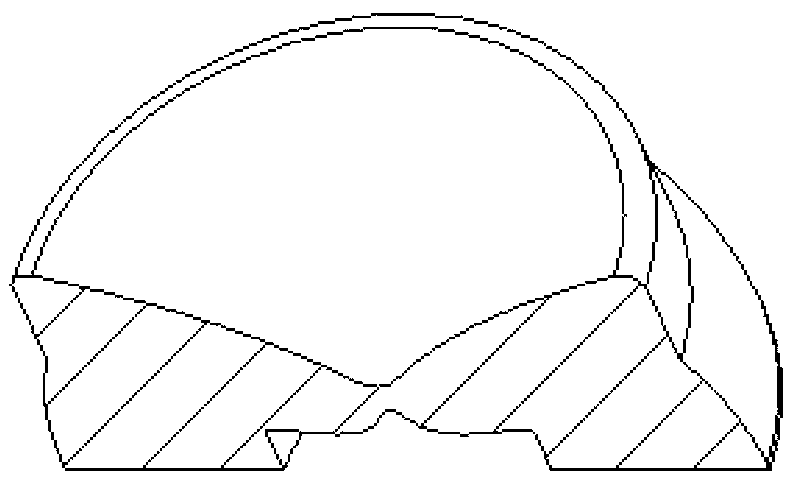

[0031] image 3 It is a cross-sectional view of the optical lens applied to the TV backlight module.

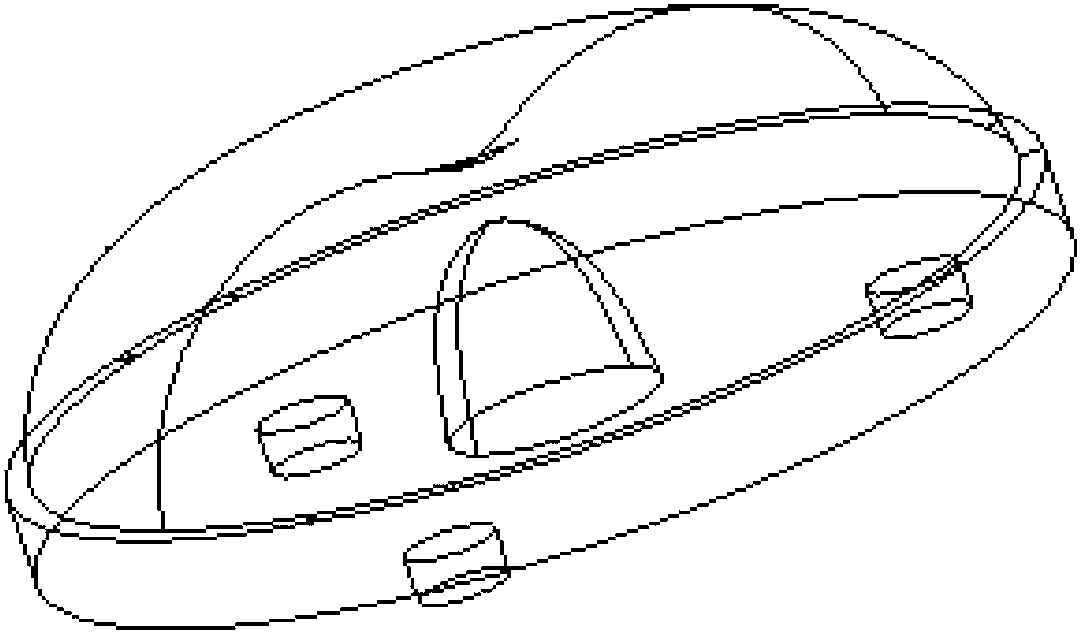

[0032] Figure 4 For this reason, the optical lens is applied to the structural diagram of the TV backlight module. The lens body 1 of the present invention is composed of a light-incident curved surface 12, at least two light-emitting curved surfaces, a bottom plane and a positioning pillar 40. The light-incident curved surface 12 formed at the bottom is a free-form surface with a center recessed upward; the light-emitting curved surface 15 formed at the top is a free-form curved surface with a center recessed downwards. The center of the light-incident curved surface 12 is recessed upwards and the center of the light exiting curved surface is recessed downwards The minimum thickness of the optical lens is 1mm, which is used to disperse the central light intensity of the LED point light source. The light-emitting curved surface 20 for...

Embodiment 2

[0036] Apply optical lens to panel light

[0037] Apply 25 pieces of this optical lens to 30w600mm x600mm panel light, 5x5 array, such as Figure 8 Shown.

[0038] The present invention has the following advantages:

[0039] 1) The present invention is formed into a shape with a thin center and thick edges, which facilitates the design of large-angle beams. The optical lens of the present invention needs to be used in conjunction with the bottom reflector. This design method can improve the light extraction efficiency of the optical lens;

[0040] 2) The light-emitting form of the present invention is refracted and matched with the reflective form. The light-emitting angle is above 270°, and the light beam above 180° is reflected by the reflective sheet placed at the bottom of the lens. It is applied to the backlight module and the refracted light is directly projected to the upper The bottom surface of the diffuser. The reflected light is emitted from the side edge of the lens, is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com