A kind of water-based environmental protection thermal insulation coating and preparation method thereof

A thermal insulation and environmental protection technology, applied in the direction of reflection/signal paint, coating, etc., can solve the problems of complex construction, increased fire conditions, and large volume of finished products, and achieve good reflection function, good thermal insulation, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

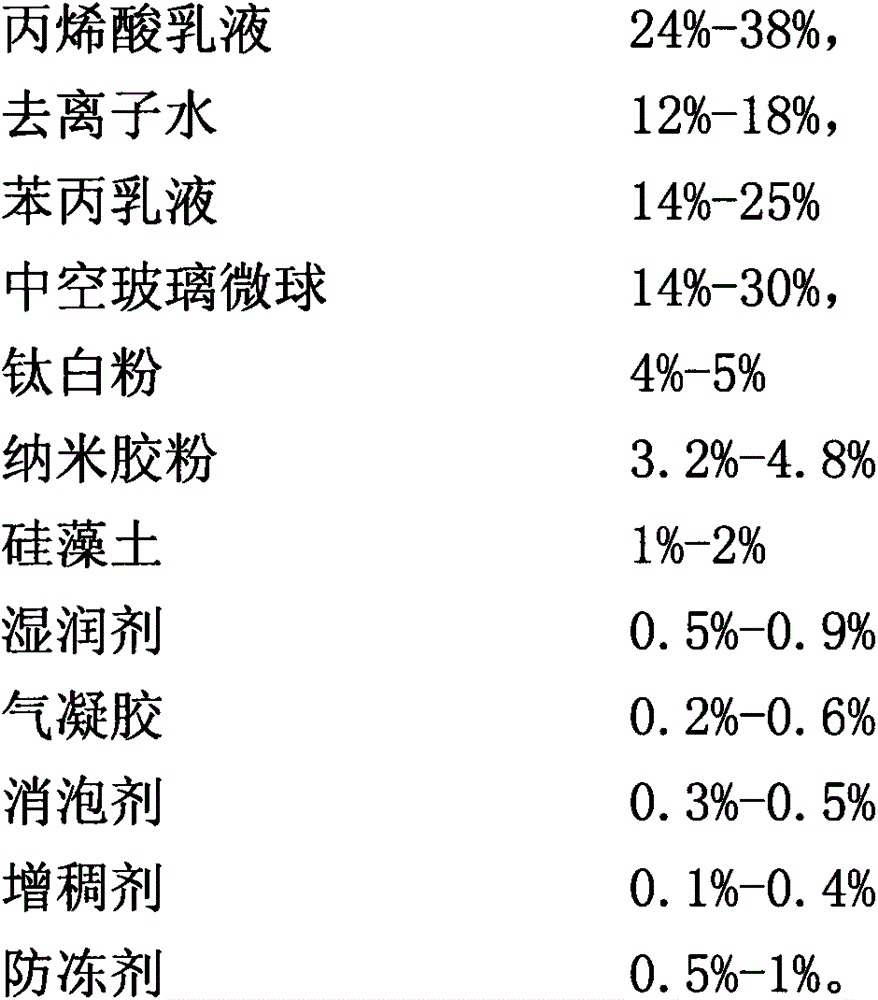

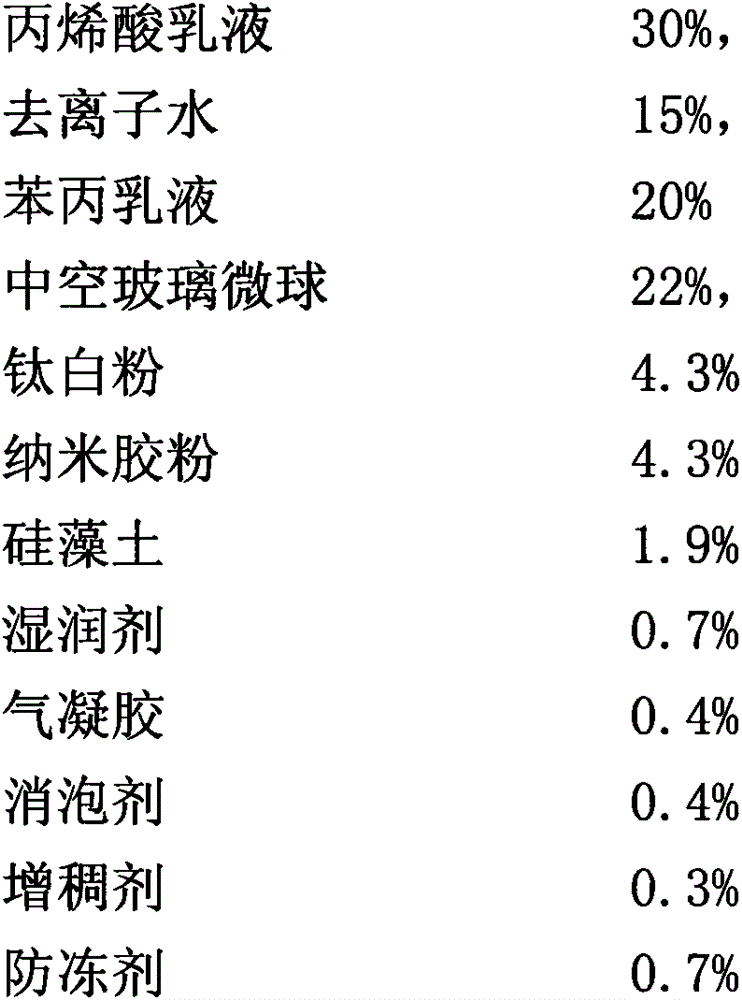

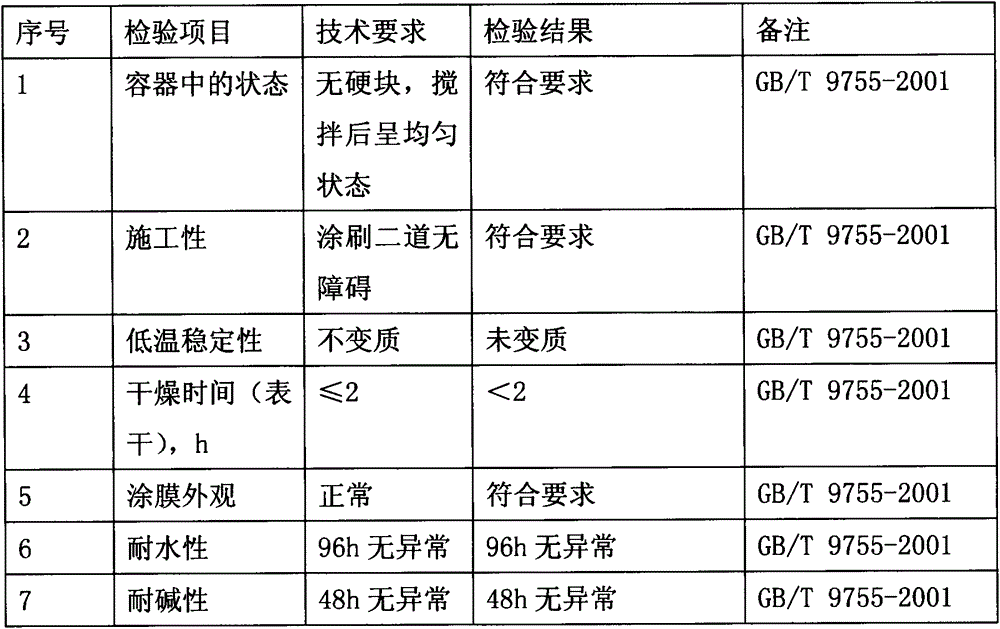

[0018] Embodiment 1 This water-based environmental protection thermal insulation coating comprises the following components calculated according to mass percentage:

[0019]

[0020] The preparation method of the water-based environmental protection thermal insulation coating comprises: adding deionized water into a stirrer, then adding airgel, wetting agent, acrylic emulsion, and styrene-acrylic emulsion in turn and stirring for 15 minutes, mixing evenly, and then adding diatomaceous earth, Stir the titanium dioxide for 20 minutes, and mix evenly; then add the remaining ingredients in sequence, stir for 30 minutes, mix evenly, and reach a uniform thick slurry state, and then filter and discharge the material, then it can be loaded into barrels.

[0021] The specific gravity of the aforementioned acrylic emulsion is 0.95-0.99, and the pH value is 7-9. The acrylic emulsion can be made by mixing and compounding SAP-600S and SAP-200H emulsions from Sanji Hwaseong Co., Ltd. in S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com