Technology for treating waste water produced by rubber accelerator production

A rubber accelerator and treatment process technology, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of long treatment process, high cost and complicated operation, and achieve The effect of compact process flow, reduced odor of wastewater, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

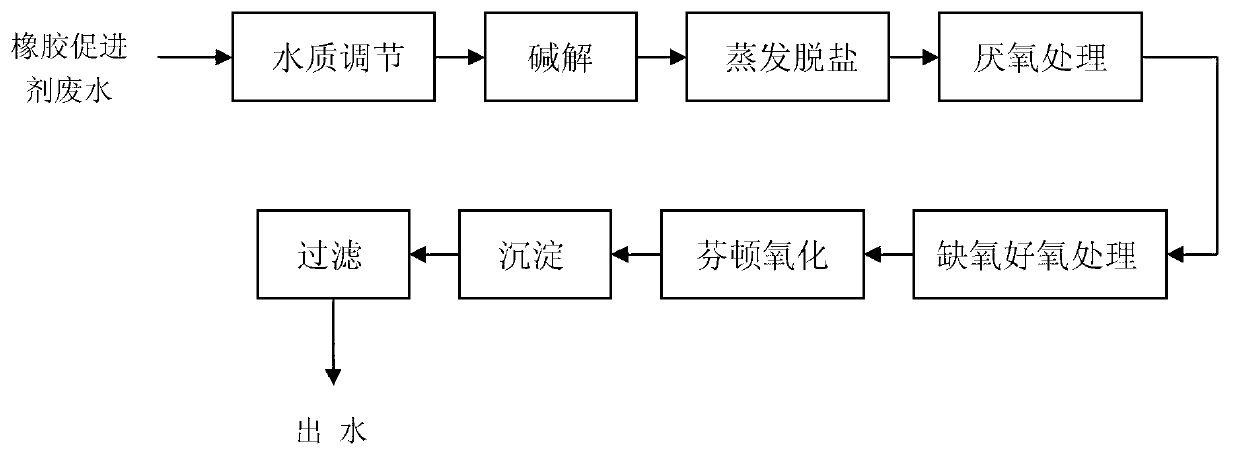

[0022] The flow chart of the treatment process of rubber accelerator production waste water of the present invention is as figure 1 Shown:

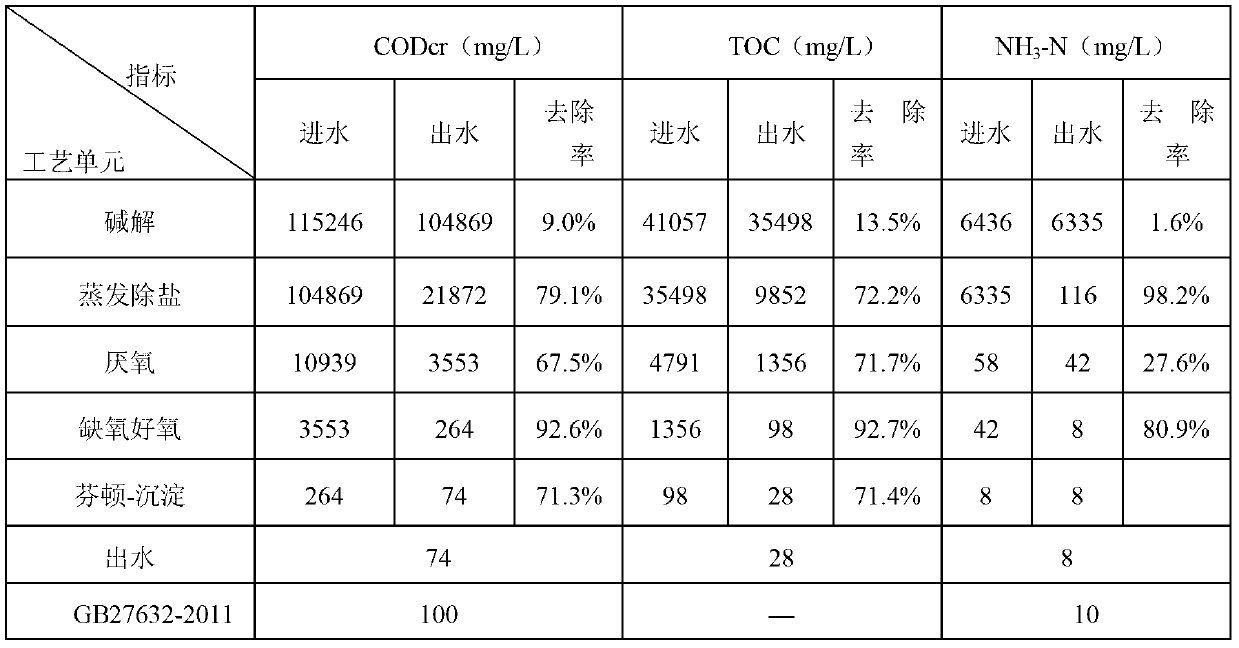

[0023] The initial CODcr115246mg / L, TOC41057mg / L, ammonia nitrogen 6436mg / L, salinity 31.2% and chromaticity below 10 in the waste water produced by a certain rubber accelerator. First adjust the water quality, then adjust the pH value of the wastewater to 11.5, adjust the temperature of the constant temperature oscillator to 70°C, put the sealed glass vessel containing the waste water into the constant temperature oscillator for alkaline hydrolysis reaction, and continue for 2 hours; at this time, the pH of the alkali hydrolysis effluent value dropped to 8.0, fine-adjust the pH value to weakly acidic 6.0 with sulfuric acid, and then use a vacuum pump to perform decompression (vacuum degree of 0.05) evaporation and desalination treatment; dilute the above-mentioned treated wastewater by 2 times, fine-adjust the pH value to 7.0, and then e...

Embodiment 2

[0026] The initial CODcr115012mg / L, TOC41036mg / L, ammonia nitrogen 6430mg / L, salinity 32.5% and chromaticity below 10 in the waste water produced by a rubber accelerator. First, adjust the water quality, then adjust the pH value of the wastewater to 12.5, adjust the temperature of the constant temperature oscillator to 85°C, put the sealed glass vessel containing the wastewater into the constant temperature oscillator for alkaline hydrolysis reaction, and continue for 3 hours; at this time, the pH of the alkali hydrolysis effluent The pH value drops back to 7.2, fine-adjust the pH value to weakly acidic 5.0 with sulfuric acid, and then perform decompression (vacuum degree of 0.045) evaporation and desalination treatment; fine-adjust the pH value of the above-mentioned wastewater to 8.0, and then enter anaerobic and anaerobic sludge The concentration is maintained at 9500mg / L, the anaerobic HRT is maintained at 24h, and the sludge reflux ratio is 1.0; the effluent from anaerobic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com