Production process of high-strength high-conductivity copper-chromium-zirconium alloy long wire

A preparation process, copper-chromium-zirconium-zirconium technology, is applied in the field of preparation process of high-strength and high-conductivity copper-chromium-zirconium alloy long wire, which can solve problems such as the decline of mechanical properties, achieve the goal of improving mechanical properties, improving mechanical and electrical properties, and relieving stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw materials such as pure copper, copper-chromium master alloy and pure zirconium are used for vacuum smelting. The chemical composition of the alloy is shown in Table 1.

[0030] Table 1 Chemical composition of the alloy (wt.%)

[0031] Alloy

Cr

Zr

Cu

Cu-0.36Cr-0.12Zr

0.36

0.15

margin

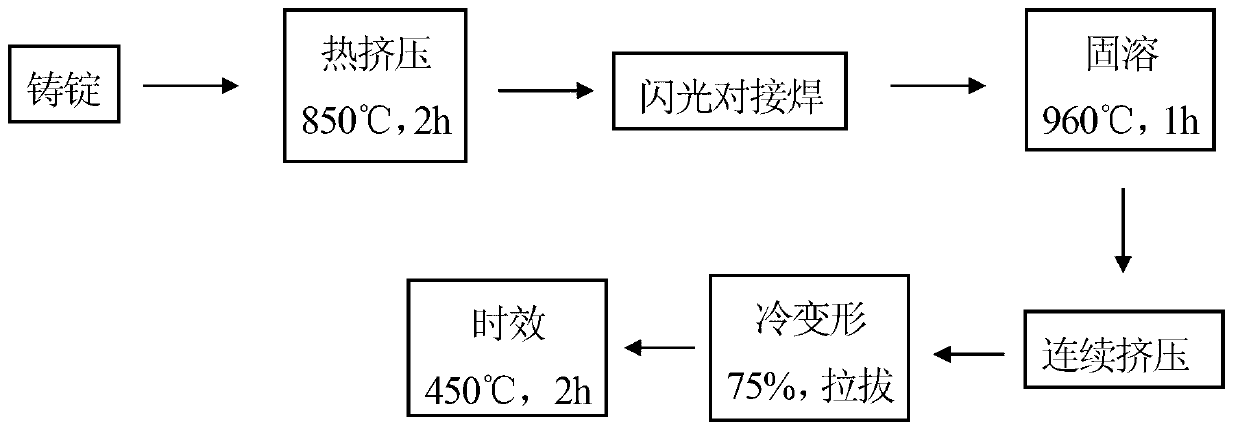

[0032] The specific production process such as figure 1 , the actual operation steps are as follows:

[0033] (1) CuCrZr alloy rods (wires) were prepared by hot extrusion for casting ingots, the hot extrusion temperature was 800-900°C, and the holding time was 1-3h (in this embodiment, the hot extrusion temperature was 850°C, and the time was 2h);

[0034] (2) Flash butt welding is used to weld alloy rods (wires). The process parameters of flash butt welding are: flash time 1-3s; flash speed 10-15mm / s; upsetting pressure: 150-200MPa; Amount of 10-15mm (in this example, flashing time 2s; flashing speed 12mm / s; upsetting pressure: 180MPa;...

Embodiment 2

[0047] Raw materials such as pure copper, copper-chromium master alloy and pure zirconium are used for vacuum smelting. The chemical composition of the alloy is shown in Table 3.

[0048]Table 3 Chemical composition of the alloy (wt.%)

[0049] Alloy

[0050] Specific steps are as follows:

[0051] (1) CuCrZr alloy rods (wires) were prepared by hot extrusion for casting ingots. The hot extrusion temperature was 840°C and the holding time was 3h;

[0052] (2) Flash butt welding is used to weld alloy rods (wires). The process parameters of flash butt welding are: flash time 3s; flash speed 10mm / s; upsetting pressure: 150MPa; upsetting allowance 10mm;

[0053] (3) Solution treatment at 950°C for 2 hours, water quenching to room temperature;

[0054] (4) Alloy rods (wires) are subjected to continuous extrusion treatment with an extrusion ratio of 0.64 and water cooled to room temperature;

[0055] During the continuous extrusion process through the continuous extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com