Odor gas treatment process in sludge

A technology of malodorous gas and treatment process, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of ineffective treatment of malodorous waste gas in sludge, and achieve the effect of prolonging the service life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the oxidizing agent is sodium hypochlorite, a mixed acid of sulfuric acid and hydrochloric acid (wherein sulfuric acid accounts for 60%, and hydrochloric acid accounts for 40%), and the alkaline absorbing liquid is sodium hydroxide.

[0031] A process for treating malodorous waste gas in sludge, comprising the following steps:

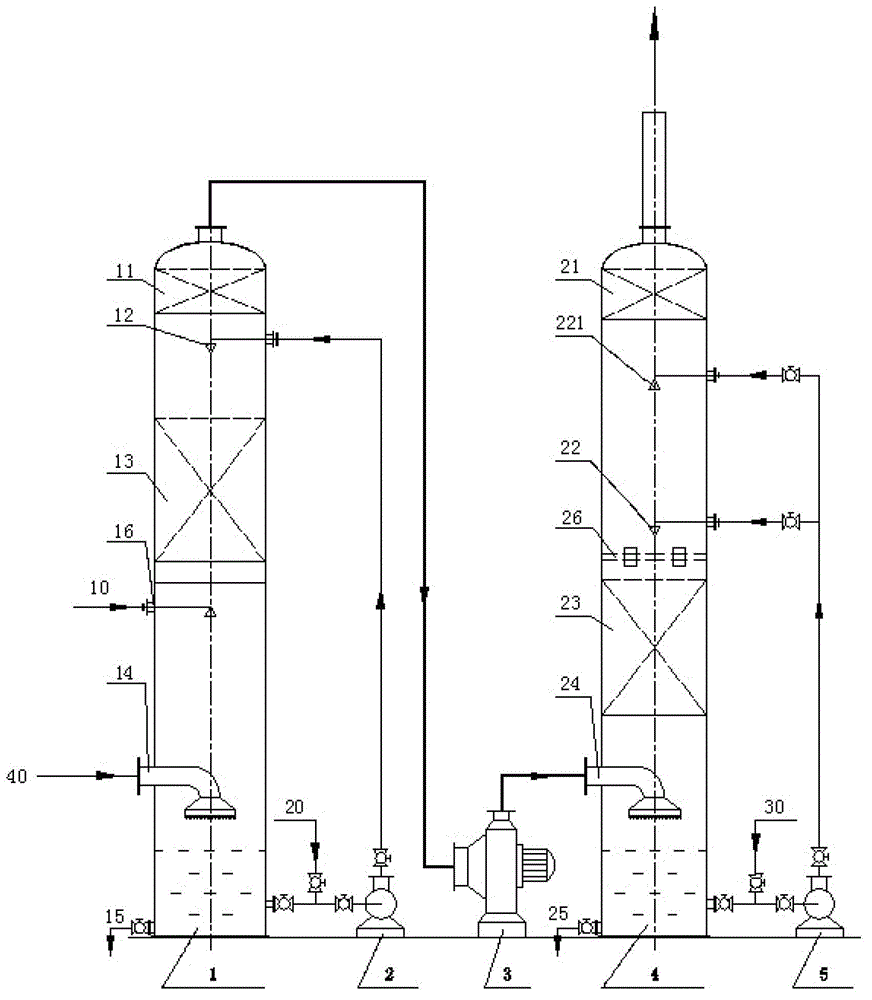

[0032] a. the sulfuric acid and hydrochloric acid mixed acid (wherein sulfuric acid accounts for 60% and hydrochloric acid accounts for 40%) with a concentration of 15% (calculated as sulfuric acid) 20 are delivered to the first nozzle 12 by the primary absorption circulation pump 2, and the first nozzle 12 will The mixed acid 20 is sprayed to the first packing layer 13, the mixed acid 20 trickles from top to bottom along the first packing layer 13 and falls to the bottom of the primary absorption tower 1, and the mixed acid 20 passes through the bottom of the primary absorption tower 1 again The primary absorption circulatio...

Embodiment 2

[0055] In this embodiment, the oxidizing agent is calcium hypochlorite, the acidic absorbing liquid is hydrochloric acid, and the alkaline absorbing liquid is sodium hydroxide.

[0056] The malodorous gas treatment process in the sludge includes the following steps:

[0057] a. Concentration is that the hydrochloric acid 20 of 10-30% is sent to the first nozzle 12 by the first pump 2, and the first nozzle 12 sprays the hydrochloric acid 20 to the first packing layer 13, and the hydrochloric acid 20 is along the first packing layer 13 from trickle from top to bottom and fall to the bottom of the primary absorption tower 1, the hydrochloric acid 20 is transported from the bottom of the primary absorption tower 1 to the first nozzle 12 again through the first pump 2, so that the hydrochloric acid 20 is recycled;

[0058] b. Calcium hypochlorite 10 is added into primary absorption tower 1 from medicament inlet 16, and calcium hypochlorite 10 reacts with hydrochloric acid 20 to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com