Preparation method for pazufloxacin mesilate for injection

A technology for pazufloxacin mesylate and injection, which is applied in the field of preparation of pazufloxacin mesylate for injection, can solve the problems of long sublimation time and excessive cost waste in the freeze-drying process, and achieves the freeze-drying process. The effect of shortened process time, reduced production costs and high quality inspection of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

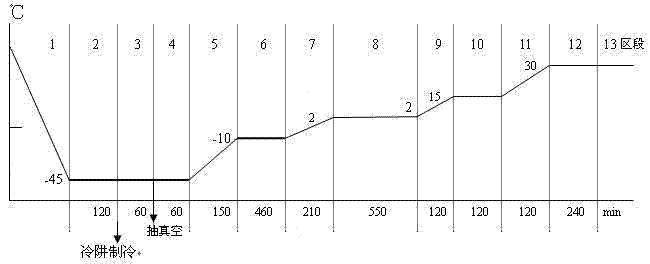

Image

Examples

Embodiment 1

[0047] Embodiment 1: the preparation method of pazufloxacin mesylate for injection, its prescription is as follows:

[0048] Pazufloxacin mesylate (calculated as Pazufloxacin): 390.6g

[0049] Mannitol: 60g

[0050] 0.1mol / L hydrochloric acid pH adjustment to 3.0~4.0

[0051] Add water for injection to 2000ml

[0052]

[0053] A total of 1000 bottles were made

[0054] Its preparation method is as follows:

[0055] 1. Precisely weigh 390.6g of the main drug pazufloxacin mesylate, add 2000ml of water for injection and stir to dissolve.

[0056] 2. Add the prescribed amount of 60g mannitol and stir to dissolve;

[0057] 3. Use 0.1mol / L HCl solution to adjust the pH value of the liquid to between 3.0 and 4.0, and add water for injection to the full amount;

[0058] 4. Add an appropriate amount of activated carbon for needles, heat to 70-80°C and stir for 15 minutes to decolorize, and filter to remove carbon;

[0059] 5. Sterilize by filtration with a 0.22 μm microporous...

Embodiment 2

[0066] Embodiment 2: the preparation method of pazufloxacin mesylate for injection, its prescription is as follows:

[0067] Pazufloxacin mesylate (calculated as Pazufloxacin): 390.6g

[0068] Mannitol: 60g

[0069] 0.1mol / L hydrochloric acid pH adjustment to 3.0~4.0

[0070] Add water for injection to 2000ml

[0071]

[0072] A total of 1000 bottles were made

[0073] Its preparation method is as follows:

[0074] 1. Precisely weigh 390.6g of the main drug pazufloxacin mesylate, add 2000ml of water for injection and stir to dissolve.

[0075] 2. Add the prescribed amount of 60g mannitol and stir to dissolve;

[0076] 3. Use 0.1mol / L HCl solution to adjust the pH value of the liquid to between 3.0 and 4.0, and add water for injection to the full amount;

[0077] 4. Add an appropriate amount of activated carbon for needles, heat to 70-80°C and stir for 20 minutes to decolorize, and filter to remove carbon;

[0078] 5. Sterilize by filtration with a 0.22 μm microporous...

Embodiment 3

[0085] Embodiment 3: the preparation method of pazufloxacin mesylate for injection, its prescription is as follows:

[0086] Pazufloxacin mesylate (calculated as Pazufloxacin): 390.6g

[0087] Mannitol: 60g

[0088] 0.1mol / L hydrochloric acid pH adjustment to 3.0~4.0

[0089] Add water for injection to 2000ml

[0090]

[0091] A total of 1000 bottles were made

[0092] Its preparation method is as follows:

[0093] 1. Precisely weigh 390.6g of the main drug pazufloxacin mesylate, add 2000ml of water for injection and stir to dissolve.

[0094] 2. Add the prescribed amount of 60g mannitol and stir to dissolve;

[0095] 3. Use 0.1mol / L HCl solution to adjust the pH value of the liquid to between 3.0 and 4.0, and add water for injection to the full amount;

[0096] 4. Add an appropriate amount of activated carbon for needles, heat to 70-80°C and stir for 18 minutes to decolorize, and filter to remove carbon;

[0097] 5. Sterilize by filtration with a 0.22 μm microporous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com