Miniaturization device for converting end feeding type coaxial line to circular waveguide

A circular waveguide and converter technology, applied to waveguide devices, electrical components, connecting devices, etc., can solve the problems of difficult processing and manufacturing, inconvenient adjustment and correction, large size, etc., and achieve easy processing and manufacturing, structural processing and manufacturable Good performance and convenient experiment debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the Ku frequency band, the operating frequency is 11GHz to 15GHz, and a 5-level ladder impedance transformation block structure is adopted.

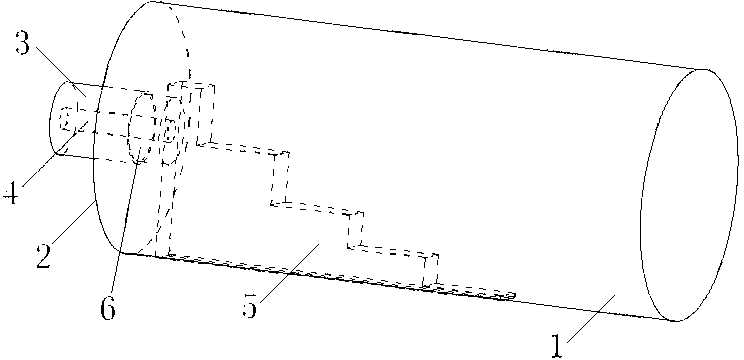

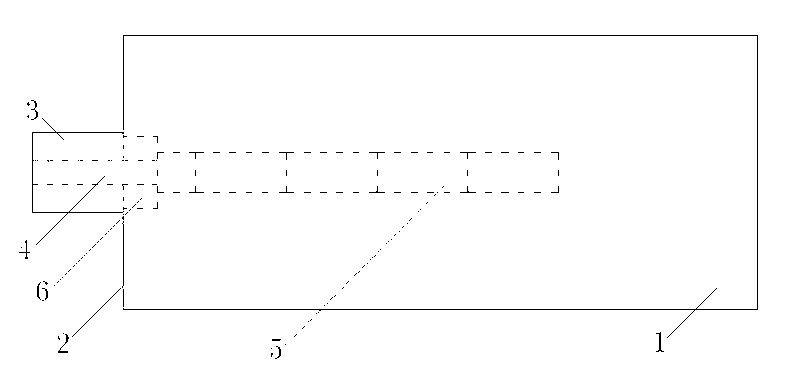

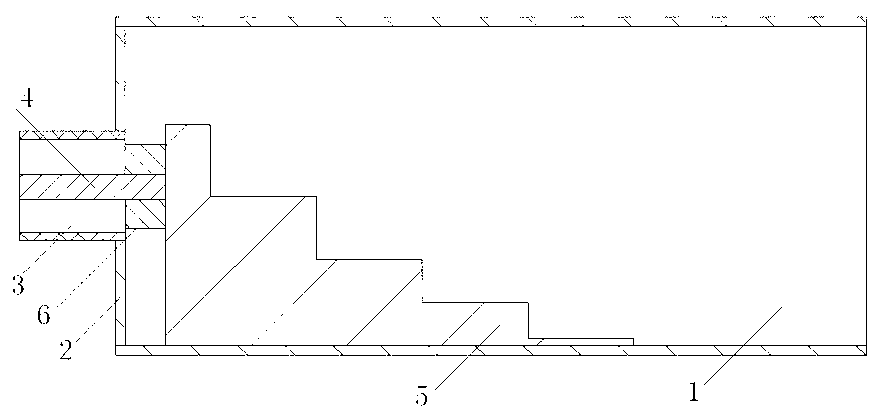

[0026] see figure 1 , figure 2 and image 3 , the miniaturized end-fed coaxial line to circular waveguide converter includes a tubular circular waveguide 1, one end of which is closed as a short-circuit end 2, and the other end is open; in the center of the short-circuit end 2 of the circular waveguide 1, a simultaneous Axial joint 3, the axial direction of the coaxial joint 3 is consistent with the transmission direction of the electromagnetic field in the circular waveguide; the inner conductor 4 of the coaxial joint 3 goes deep into the interior of the circular waveguide 1, and is connected to the five-level metal ladder impedance transformation block 5 In the first stage, the inner conductor 4 extends into the circular waveguide 1 to a depth of one-eighth of the working wavelength of the converter. The bottom surface o...

Embodiment 2

[0033] Ku frequency band, operating frequency is 11GHz ~ 15GHz, adopts seven-step impedance transformation block structure, see Figure 4 .

[0034] 1. Selection of circular waveguide 1 and coaxial connector 3

[0035] Generally, according to the required working frequency range, select a circular waveguide with a corresponding diameter: the diameter of the circular waveguide is 16.5mm; the coaxial connector 3 can be selected from the SMA standard coaxial connector according to the needs of use.

[0036] 2. Determination of parameters

[0037] The depth of the inner conductor 4 extending into the interior of the circular waveguide 1 is one-eighth of the working wavelength of the converter; the outer diameter of the dielectric ring 6 is 2.65mm; the width of the seven-step impedance transformation block 5 is 2.6mm; the width of each level Same; the length of the first stage of the seven-stage ladder impedance transformation block 5 is one-eighth of the working wavelength of th...

Embodiment 3

[0040] X-band, operating frequency is 8GHz ~ 12GHz, adopts seven-step impedance transformation block structure, see Figure 4 .

[0041] 1. Selection of circular waveguide 1 and coaxial connector 3

[0042] Generally, according to the required operating frequency range, select a circular waveguide with a corresponding diameter: the diameter of the circular waveguide is 20mm; the coaxial connector 3 can be selected from the SMA standard coaxial connector according to the needs of use.

[0043]2. Determination of parameters

[0044] The depth of the inner conductor 4 extending into the interior of the circular waveguide 1 is one-eighth of the working wavelength of the converter; the outer diameter of the dielectric ring 6 is 2.65mm; the width of the seven-step impedance transformation block 5 is 4.8mm; the width of each level Same; the length of the first stage of the seven-stage ladder impedance transformation block 5 is one-eighth of the working wavelength of the converter, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com