One-shot optical disc with surface plasmon enhancement

A surface plasmon and enhancement effect technology, applied in data recording, recording information storage, optical recording/reproduction, etc., can solve problems such as complex film structures, achieve simple film structure, and improve readout signal-to-noise ratio , Improve the effect of storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

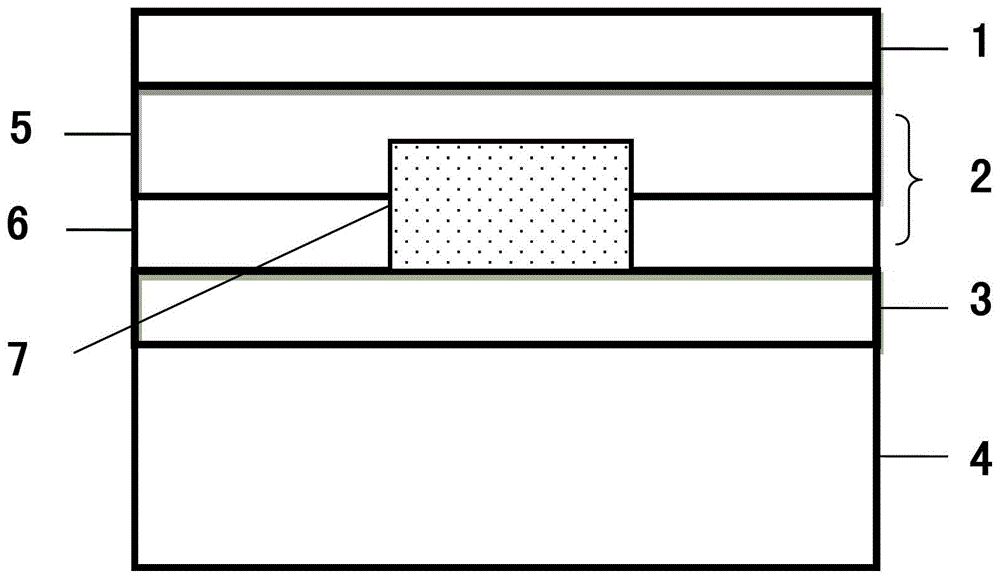

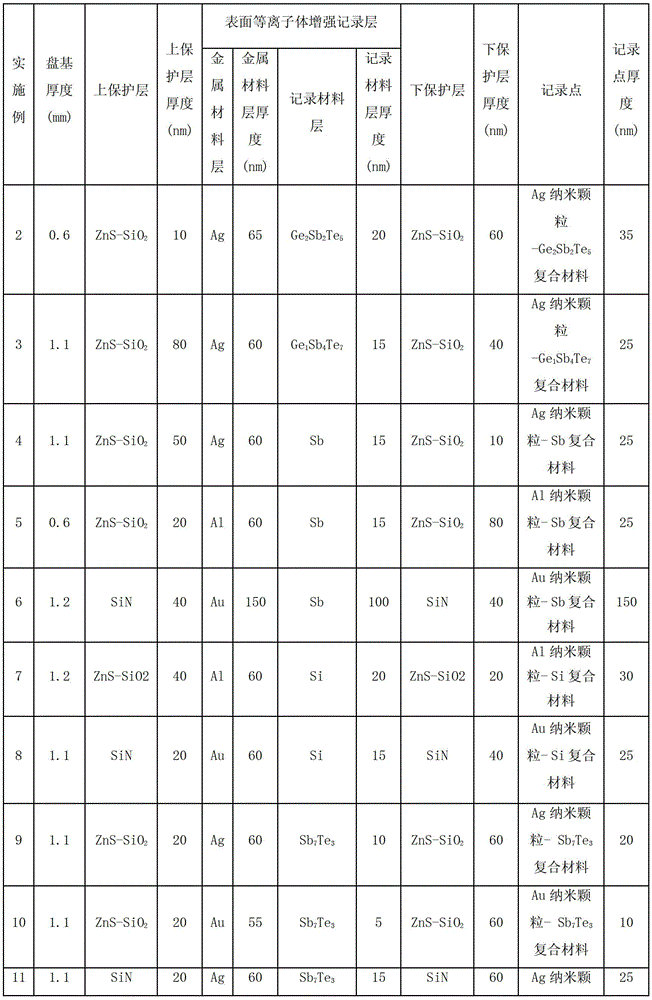

[0021] A lower protective layer 3 , a recording material layer 6 , a metal material layer 5 and an upper protective layer 1 are sequentially prepared on the disc substrate 4 by magnetron sputtering. The metal material layer 5 and the recording material layer 6 jointly constitute the surface plasmon enhanced recording layer 2 . Wherein the disc base 4 is made of polycarbonate with a thickness of 1.2mm. The lower protective layer 3 is ZnS-SiO with a thickness of 60nm 2 Thin film, the recording material layer 6 is a 15nm thick GeSb-SbTe thin film (specific chemical composition Ge 2 Sb 2 Te 5 ), the metal material layer 5 is a Ag film with a thickness of 60nm, and the upper protective layer 1 is a ZnS-SiO with a thickness of 20nm 2 film.

[0022] When the writing laser acts, a part of the metal material layer 5 in the surface plasmon-enhanced recording layer 2 is fused with the recording material layer 6 to form recording points 7 in which metal nanoparticles are dispersed an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com