Small-flow high-pressure compact type balance valve

A balance valve and high-pressure technology, which is applied in fluid pressure actuators, fluid pressure actuator system components, servo motor components, etc., can solve problems such as shortening the service life of hydraulic cylinders, uncontrollable equipment, and damage to hydraulic cylinders. Achieve fast cleaning, sensitive response and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

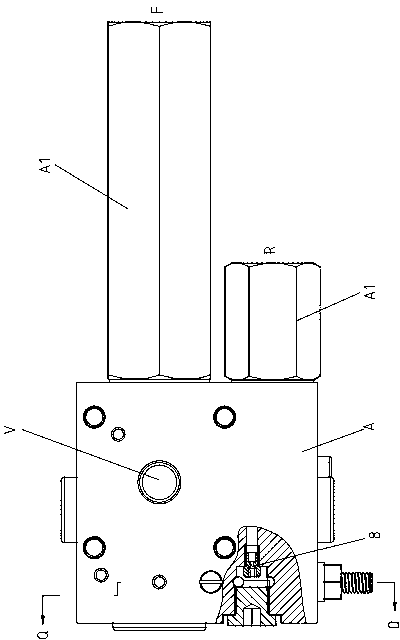

[0027] Figure 1 to Figure 10 Shown is the structural representation of the present invention.

[0028] The reference signs are: oil inlet a, oil outlet b, buffer inlet c, buffer outlet d, control input end e, control output end f, oil return end g, valve block cavity k, forward guide hole m, Small hole n, oil passage p, balance valve body A, main oil port joint A1, R port joint A2, sealing block A3, first main oil port F, second main oil port V, oil return tank port R, control Oil port S, first main oil pressure gauge port Z, second main oil pressure gauge port M, balance main valve 1, control valve block 1a, rear spring 1b, filter screen 1c, balance plate 1d, valve sleeve 1e, valve core 1f, spring seat 1g, front spring 1h, pressure adjustment screw 1i, connecting rod 1j, buffer valve 2, buffer valve sleeve 2a, buffer valve core 2b, valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com